Biodegradable copolyester nanometer composite material and temporary plugging agent prepared from biodegradable copolyester nanometer composite material

A technology of nanocomposite materials and inorganic nanomaterials, applied in the direction of single-component polyester rayon, rayon manufacturing, and drilling compositions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

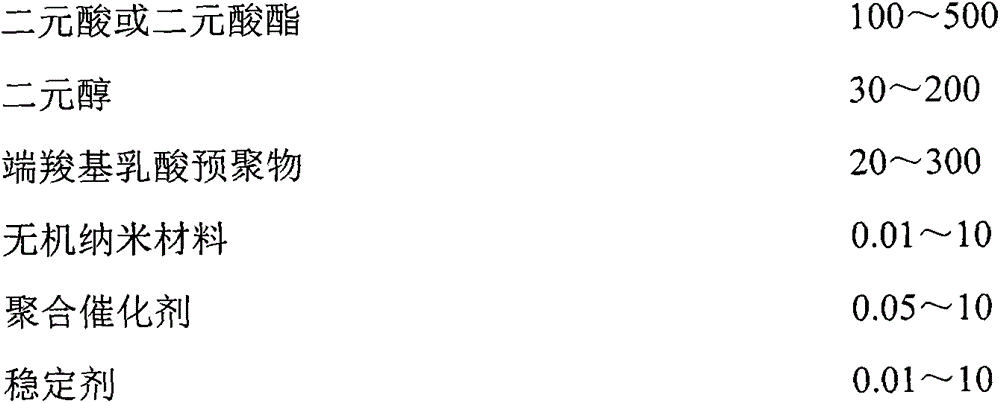

Method used

Image

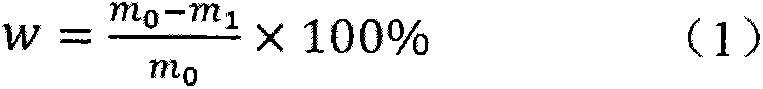

Examples

Embodiment 1

[0050] Take 300g of L-lactic acid and keep stirring in a 500ml three-necked flask. First, distill under reduced pressure for 2-4 hours at a temperature of 60-100°C and a vacuum of 6.5-3.5mmHg to remove free water and bound water in the raw materials; then add The catalyst is 1.52g of stannous octoate, and it is reacted for 6-10 hours at a temperature of 120-165°C and a vacuum of 2.5-1mmHg; finally, 4.91g of adipic acid is added to keep the reaction temperature at 165-170°C and a vacuum of 2.5 ~1mmHg, carry out the capping reaction for 4~6h to obtain the carboxyl-terminated lactic acid prepolymer with a viscosity-average molecular weight of 5836.

Embodiment 2

[0052] Based on the synthesis process parameters of Example 1, get 3000g of L-lactic acid, 12.31g of stannous octoate, and 49.98g of end-capping agent, and carry out the synthesis of carboxyl-terminated lactic acid prepolymer in a pilot scale reactor with a volume of 12L to obtain A carboxyl-terminated lactic acid prepolymer with a viscosity-average molecular weight of 5890.

Embodiment 3

[0054] Take 1,500g of terephthalic acid and 703ml of ethylene glycol in a 12L pilot test reactor under nitrogen protection to carry out esterification reaction for 3 hours with continuous stirring. The esterification temperature is 230-250°C and the esterification pressure is 0.23-0.28MPa. After completion, 0.78 g of antimony ethylene glycol and 0.70 g of triphenyl phosphate were added, and the polymerization reaction was carried out under the conditions of a vacuum of 0.05-1 mmHg and a temperature of 260-280 ° C. The intrinsic viscosity and melting point data of the obtained samples are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com