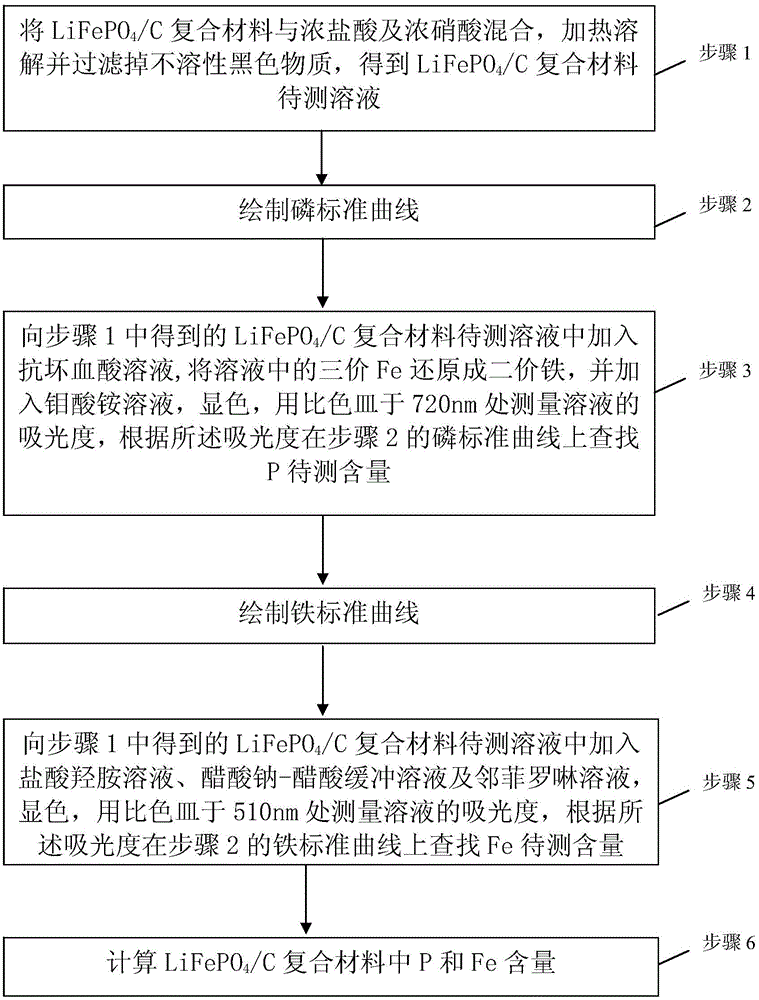

Method for detecting content of phosphorus and iron in LiFePO4/C composite material

A composite material and detection method technology, applied in the measurement of color/spectral characteristics, etc., can solve the problems of test error and test instability, test accuracy deviation, time-consuming constant weight, etc., to achieve a simple test method and easy operation. ,Reliable quality control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] 1. Prepare lithium iron phosphate test solution:

[0073] Weigh 0.1g of the sample into a 50ml beaker, add 6ml of concentrated hydrochloric acid and 6ml of concentrated nitric acid, place the beaker on a heating plate at 80°C and heat to dissolve for 10min, pay attention to cover the beaker with a watch glass during heating to prevent the acid from volatilizing. After the sample is completely dissolved, filter it into a 250ml volumetric flask through double-layer filter paper to remove the black insoluble carbon impurities in the sample, and wash the residual liquid on the beaker and filter paper several times to ensure no loss of raw materials. Finally distill and dilute to the mark to obtain the lithium iron phosphate sample treatment solution.

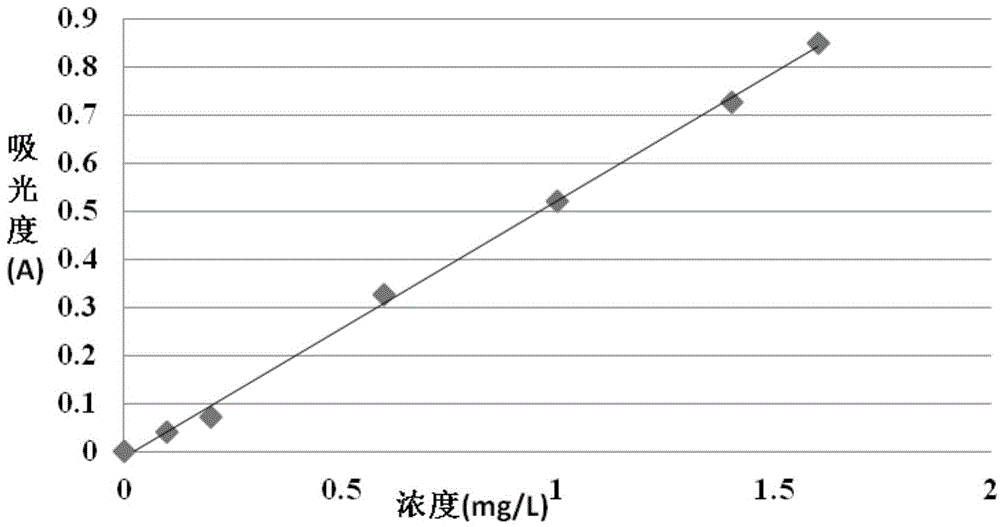

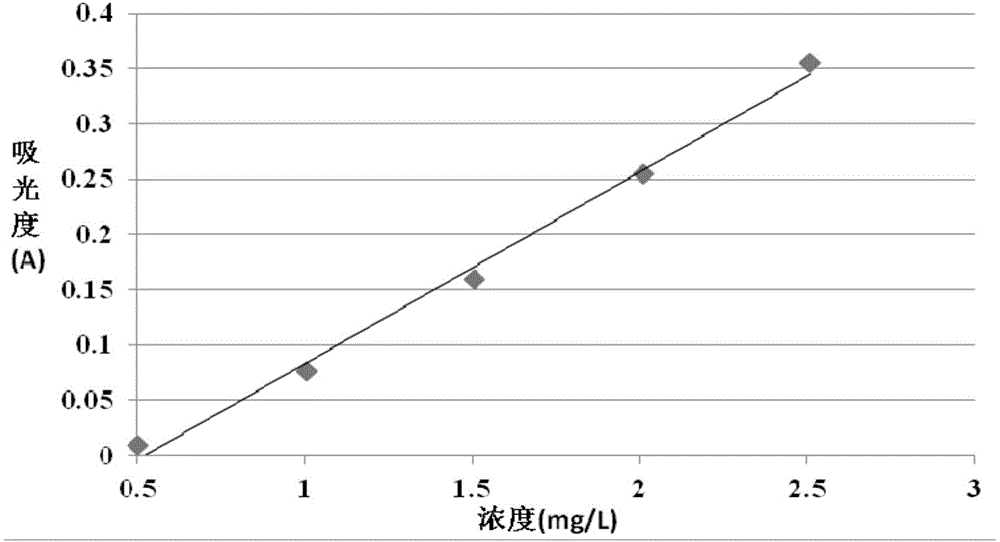

[0074] 2. Test of phosphorus content in the sample

[0075] (1) Preparation of reagents:

[0076] Ammonium molybdate solution: Weigh 10g of ammonium molybdate and 0.3g of oxyantimony potassium tartrate, dissolve them in a s...

Embodiment 2

[0098] 1. Prepare lithium iron phosphate test solution:

[0099] Weigh 0.11g of sample into a 50ml beaker, add 10ml of concentrated hydrochloric acid and 10ml of concentrated nitric acid, place the beaker on a 70°C heating plate and heat to dissolve for 5min, pay attention to cover the beaker with a watch glass during heating to prevent the acid from volatilizing. After the sample is completely dissolved, filter it into a 250ml volumetric flask through double-layer filter paper to remove the black insoluble carbon impurities in the sample, and wash the residual liquid on the beaker and filter paper several times to ensure no loss of raw materials. Finally distill and dilute to the mark to obtain the lithium iron phosphate sample treatment solution.

[0100] 2. Test of phosphorus content in the sample

[0101] (1) Preparation of reagents:

[0102] Ammonium molybdate solution: Weigh 10g of ammonium molybdate and 0.5g of oxyantimony potassium tartrate, dissolve them in a small ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com