A kind of antistatic biodegradable film and preparation method thereof

A biodegradable and antistatic technology, applied in the field of materials, can solve the problems that the film properties need to be further improved, limit the application of biodegradable material films, and have no antistatic properties, so as to reduce electrostatic aggregation, complete degradation, and excellent mechanical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

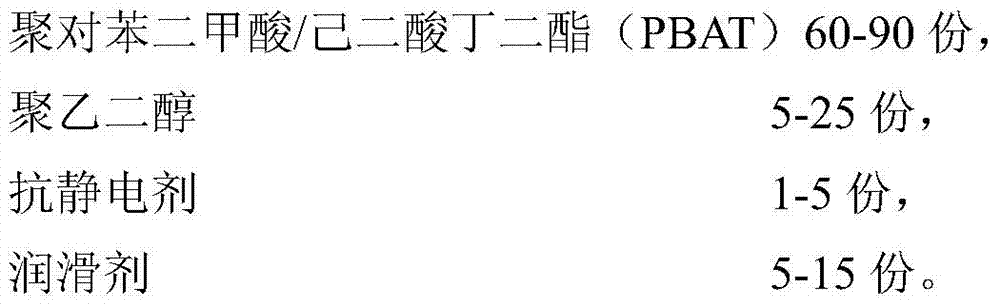

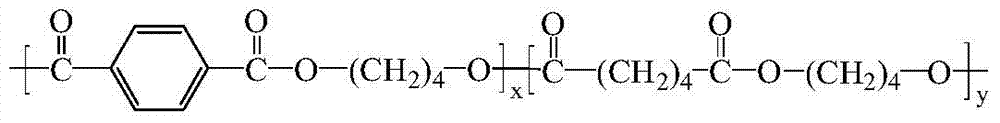

Method used

Image

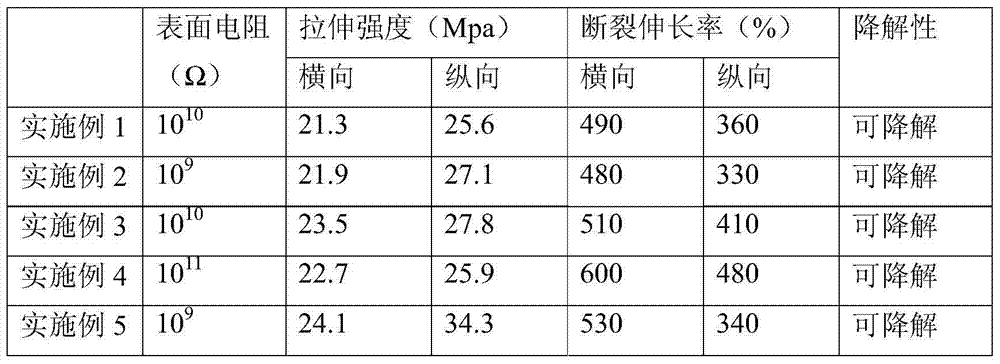

Examples

Embodiment 1

[0030] (1) Dry the PBAT at a drying temperature of 70°C and a drying time of 9 hours;

[0031] (2) Weigh 70 parts of polybutylene terephthalate / adipate, 15 parts of polyethylene glycol, 3 parts of antistatic agent (polyamide), and 12 parts of lubricant (stearic acid amide). Mix evenly in the mixer, and the mixing time is 5 minutes;

[0032] (3) Add the mixed materials into a twin-screw extruder for melt blending, then strand and pelletize to obtain blended polyester pellets, and the extrusion temperature is 110°C;

[0033] (4) Blow the blended polyester particles and lubricant through a film blowing machine to obtain an antistatic degradable polyester film. The feeding temperature of the film blowing machine is set at 130°C, and the temperature of the plasticizing section is set at 165°C , and the die temperature was set to 155°C.

Embodiment 2

[0035] (1) Dry the PBAT at a drying temperature of 60°C and a drying time of 10 hours;

[0036] (2) Weigh 60 parts of polybutylene terephthalate / adipate, 25 parts of polyethylene glycol, 5 parts of antistatic agent (polyoxyethylene ether), 15 parts of lubricant (methylene bis stearamide) Parts, mix evenly in a high mixer, mixing time 3min;

[0037] (3) Put the mixed material into a twin-screw extruder for melt blending, then strand and pelletize to obtain blended polyester pellets, and the extrusion temperature is 100°C;

[0038] (4) Blow the blended polyester particles and lubricant through a film blowing machine to obtain an antistatic degradable polyester film. The feeding temperature of the film blowing machine is set at 120°C, and the temperature of the plasticizing section is set at 150°C , the die temperature was set to 150 °C.

Embodiment 3

[0040] (1) Dry the PBAT at a drying temperature of 80°C and a drying time of 8 hours;

[0041] (2) Weigh 80 parts of polybutylene terephthalate / adipate, 10 parts of polyethylene glycol, 2 parts of antistatic agent (trialkylaniline salt), lubricant (calcium stearate, stearin Zinc acid) 4 parts each, mix evenly in a high-speed mixer, and the mixing time is 7 minutes;

[0042] (3) Put the mixed material into a twin-screw extruder for melt blending, then strand and pelletize to obtain blended polyester pellets, and the extrusion temperature is 120°C;

[0043] (4) Blow the blended polyester particles and lubricant through a film blowing machine to obtain an antistatic degradable polyester film. The feeding temperature of the film blowing machine is set at 135°C, and the temperature of the plasticizing section is set at 160°C , the die temperature was set to 160 °C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface resistance | aaaaa | aaaaa |

| Transverse tensile strength | aaaaa | aaaaa |

| Longitudinal tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com