Resonance tunneling diode with double InGaN sub quantum wells and manufacturing method thereof

A resonant tunneling and diode technology, applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of high activation energy and defect density, device I-V characteristic attenuation, high interface roughness, etc., to reduce dislocation density and activation performance, lower threshold voltage, and lower power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

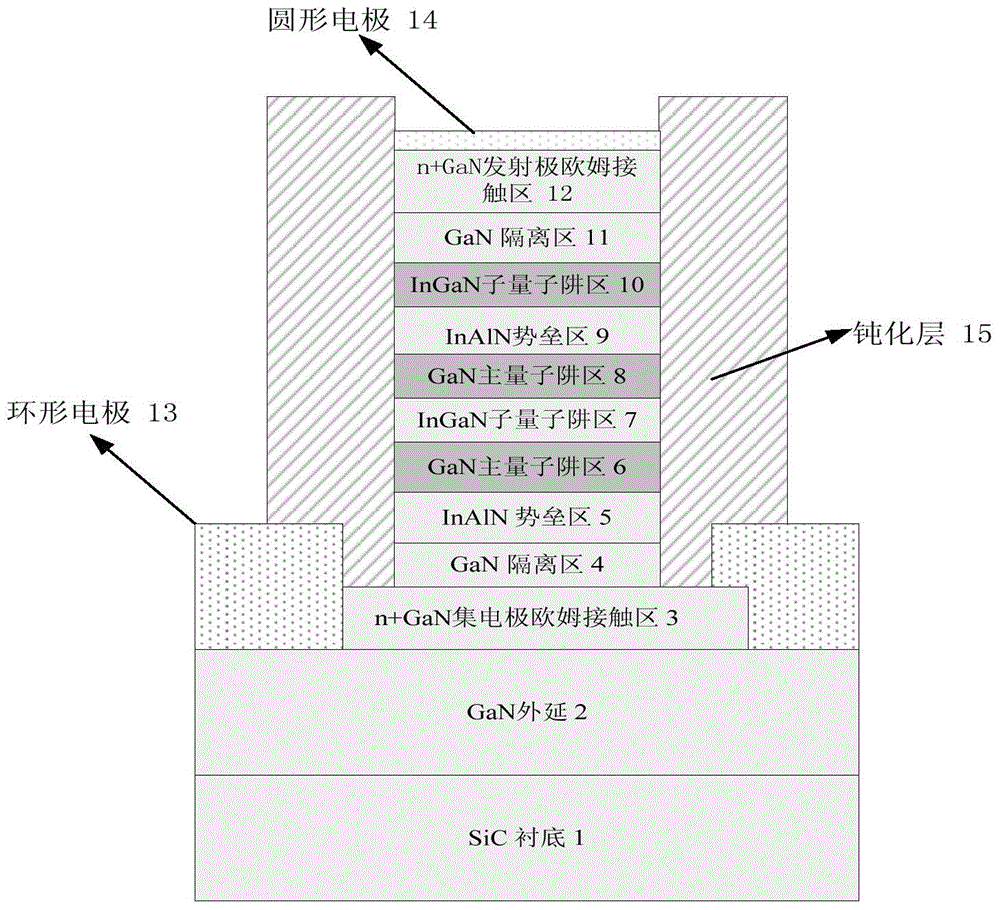

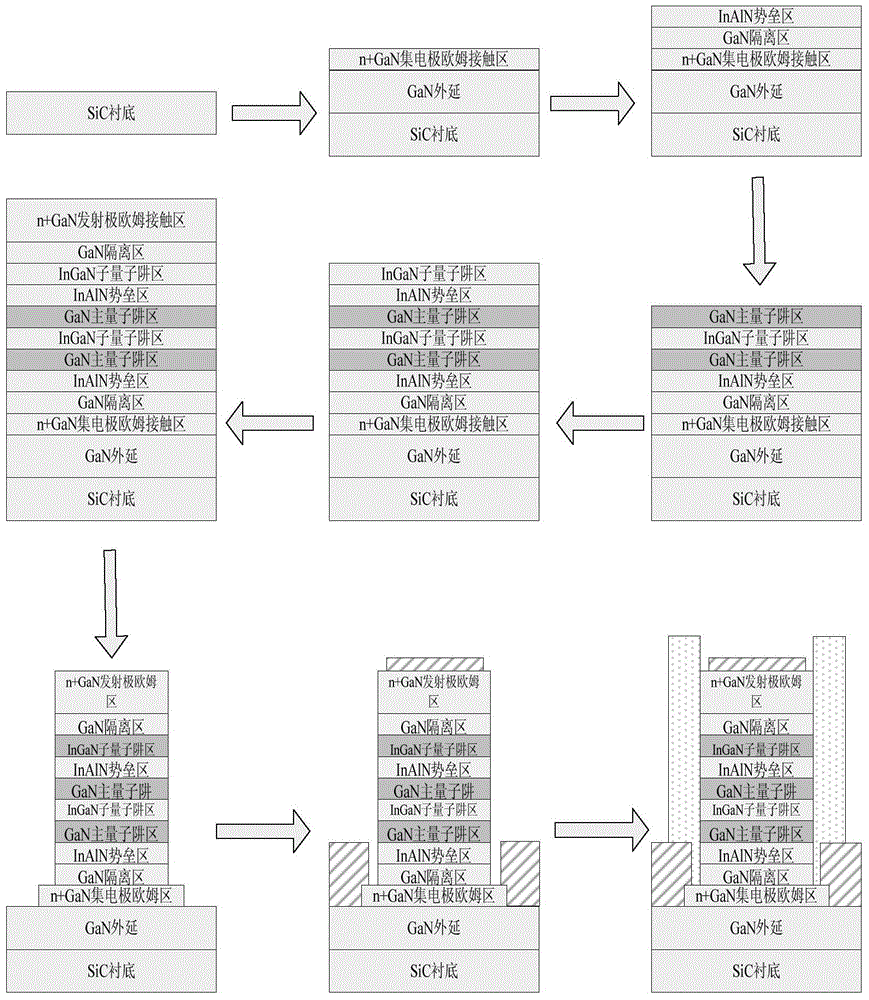

[0040] Embodiment 1: Fabricate a resonant tunneling diode with a first InGaN sub-quantum well layer with a thickness of 0.8nm and an In composition of 3% and a second InGaN sub-quantum well layer with a thickness of 0.8nm and an In composition of 3%.

[0041] In step 1, a SiC substrate is selected.

[0042] A 4H-SiC insulating SiC substrate with a diameter of 2 inches is selected, and the back side thereof is thinned to a thickness of 150 μm.

[0043] Step 2, epitaxial GaN layer on SiC substrate.

[0044] Using triethylgallium and high-purity nitrogen as the source of gallium and nitrogen respectively, under the conditions of temperature 450 ℃ and pressure 40 torr, metal-organic chemical vapor deposition MOCVD method was used to epitaxially grow thickness 2 μm GaN layer.

[0045] Step 3, grow n on the GaN epitaxial layer + GaN collector ohmic contact layer.

[0046] Using triethylgallium and high-purity nitrogen as the gallium source and nitrogen source respectively, using...

Embodiment 2

[0084] Embodiment 2: Fabricate a resonant tunneling diode with a first InGaN sub-quantum well layer with a thickness of 1 nm and an In composition of 5% and a second InGaN sub-quantum well layer with a thickness of 1 nm and an In composition of 5%.

[0085] Step 1: Select a 6H-SiC insulating SiC substrate with a diameter of 2 inches, and thin the back surface to a substrate thickness of 150 μm.

[0086] Step 2, using triethylgallium and high-purity nitrogen as the gallium source and nitrogen source respectively, using metal organic chemical vapor deposition MOCVD method, under the process conditions of temperature of 450 °C and external pressure of 40 Torr, the epitaxial growth thickness is 2μm GaN layer.

[0087] Step 3, using high-purity nitrogen gas and triethylgallium as the nitrogen source and gallium source respectively, and silane gas as the n-type doping source, using metal organic chemical vapor deposition MOCVD method, at a temperature of 1000 ° C and a pressure of 4...

Embodiment 3

[0104] Embodiment 3: Fabricate a resonant tunneling diode with a first InGaN sub-quantum well layer with a thickness of 1.2nm and an In composition of 7% and a second InGaN sub-quantum well layer with a thickness of 1.2nm and an In composition of 7%.

[0105] Step A, select a 6H-SiC conduction-type n-type SiC substrate with a diameter of 2 inches, and a doping concentration of 2.0×10 18 cm -3 , the backside is thinned to a substrate thickness of 150 μm.

[0106] Step B, epitaxially growing a GaN layer, n + GaN collector ohmic contact layer and GaN isolation layer:

[0107] (B1) Using triethylgallium and high-purity nitrogen as gallium source and nitrogen source, using metal organic chemical vapor deposition MOCVD method, under the process conditions of temperature 450 ℃ and pressure 40 torr, epitaxial growth on the substrate GaN layer with a thickness of 3 μm;

[0108] (B2) using the same nitrogen source and gallium source as in (B1), using silane gas as the n-type doping ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com