Composite all-solid-state polymer electrolyte and preparation method thereof

An all-solid polymer and electrolyte technology, which is applied in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, circuits, etc., can solve the problems of unstable electrochemical properties of electrolytes, achieve improved interface compatibility, improve mechanical properties, and improve electrochemical performance. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

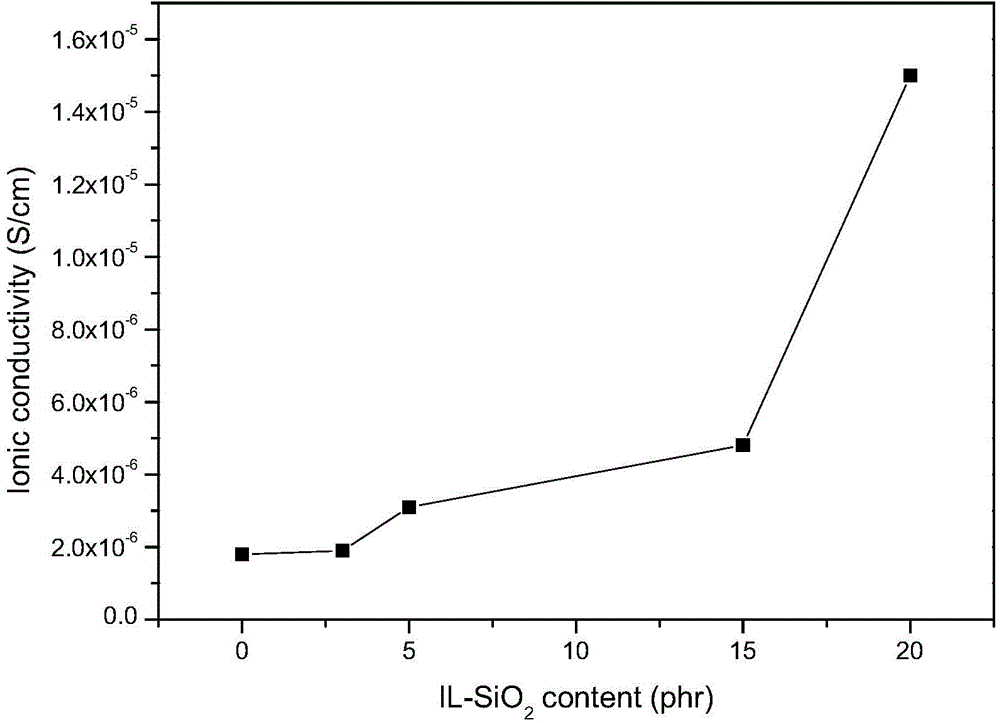

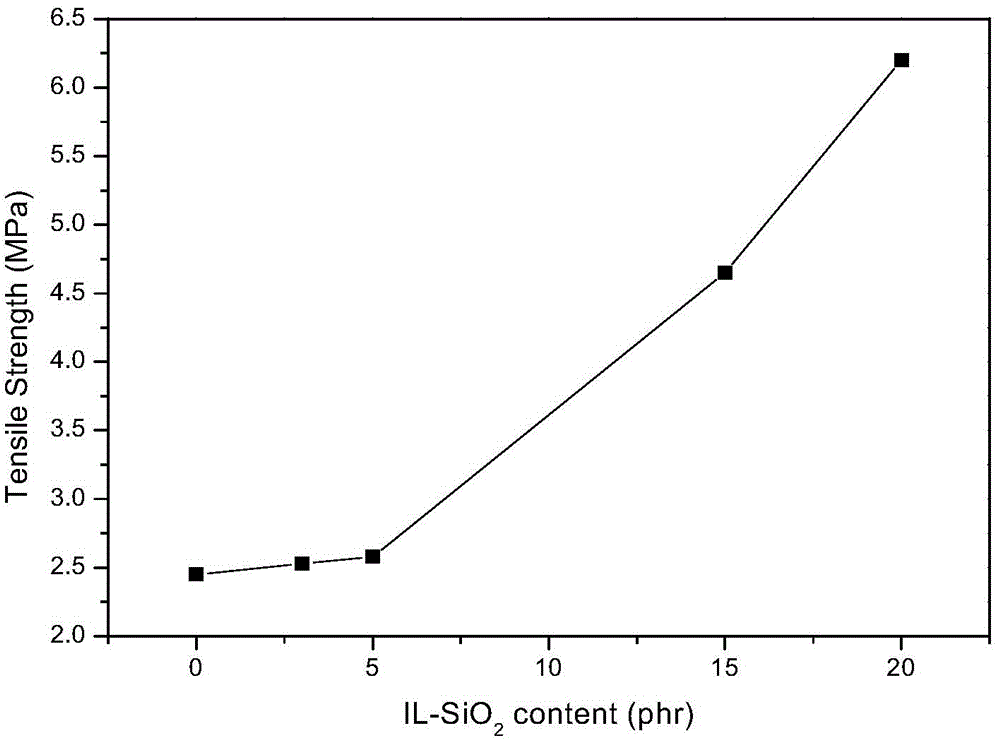

Embodiment 1~4

[0046] (1)IL-SiO2 2 preparation of

[0047] Add a certain proportion of polyoxyethylene-polyoxypropylene-polyoxyethylene block copolymer (P123), 12mol / L HCl aqueous solution, and deionized water into the flask, stir at 40°C until P123 is completely dissolved, and orthosilicic acid Add ethyl ester to the flask, continue stirring for 24 hours, raise the temperature to 90°C, stop stirring, crystallize for 24 hours, wash with deionized water and ethanol after separation by suction filtration, extract at 130°C for 24 hours, and extract the powder Dry in a vacuum oven at 80°C for 4 hours to obtain mesoporous SiO 2 .

[0048] Mesoporous SiO 2Disperse in dewatered DMF solvent and sonicate for 1h. Dissolve the quantitative IL in the dewatered dimethylformamide (DMF) solvent, and add dropwise 4-dimethylaminopyridine (DMAP) and dicyclohexyl in the ice-water bath and stirring condition, respectively. Carbodiimide (DCC), after 1h dropwise addition of mesoporous SiO 2 Dispersions. Af...

Embodiment 5

[0070] A composite all-solid polymer electrolyte, which is prepared by using the raw materials of the following components and contents;

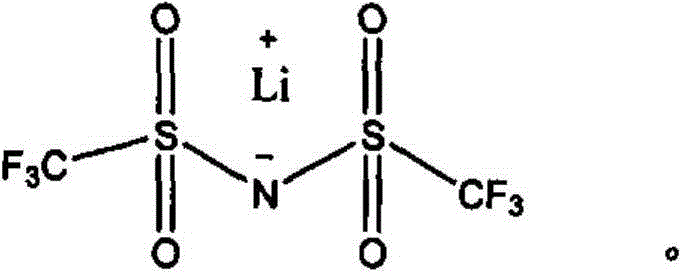

[0071] Carboxylated nitrile rubber 1kg; vulcanizing agent 0.02kg; lithium salt 0.2kg; IL-SiO 2 0.01kg. Among them, the Mooney viscosity ML of carboxylated nitrile rubber 1+4 It is 40 at 100°C, wherein the content of acrylonitrile is 27wt%, and the content of carboxyl group is 5wt%. The vulcanizing agent is dicumyl peroxide. The lithium salt is lithium bistrifluoroformimide, and its structural formula is as follows:

[0072]

[0073] IL-SiO 2 It is a complex of 1-carboxymethyl-3-methylimidazole bistrifluoromethanesulfonimide salt (ionic liquid, abbreviated as IL) and mesoporous silica. The molecular structure of IL is as follows:

[0074]

[0075] Mesoporous SiO 2 The pore size is 4nm, and it is prepared by the following method: add polyoxyethylene-polyoxypropylene-polyoxyethylene block copolymer, 12mol / L HCl aqueous solution, an...

Embodiment 6

[0086] A composite all-solid polymer electrolyte, which is prepared by using the following components and contents of raw materials:

[0087] Carboxylated nitrile rubber 1kg; vulcanizing agent 0.03kg; lithium salt 0.6kg; IL-SiO 2 0.5kg. Among them, the Mooney viscosity ML of carboxylated nitrile rubber i+4 It is 50 at 100°C, wherein the acrylonitrile content is 29 wt%, and the carboxyl content is 7 wt%. The vulcanizing agent is dicumyl peroxide. The lithium salt is lithium bistrifluoroformimide, and its structural formula is as follows:

[0088]

[0089] IL-SiO 2 It is a complex of 1-carboxymethyl-3-methylimidazole bistrifluoromethanesulfonimide salt (ionic liquid, abbreviated as IL) and mesoporous silica. The molecular structure of IL is as follows:

[0090]

[0091] Mesoporous SiO 2The pore size is 8nm, and it is prepared by the following method: add polyoxyethylene-polyoxypropylene-polyoxyethylene block copolymer, 12mol / L HCl aqueous solution, and deionized wate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Ionic conductivity at room temperature | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com