The method of one-time fruiting of bag-grown shiitake mushrooms

A technology for shiitake mushrooms and bag cultivation, which is applied in the field of edible fungi production, can solve the problems of low biotransformation rate, low biotransformation efficiency, long fruiting cycle of mushroom sticks, etc. The effect of fruiting speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

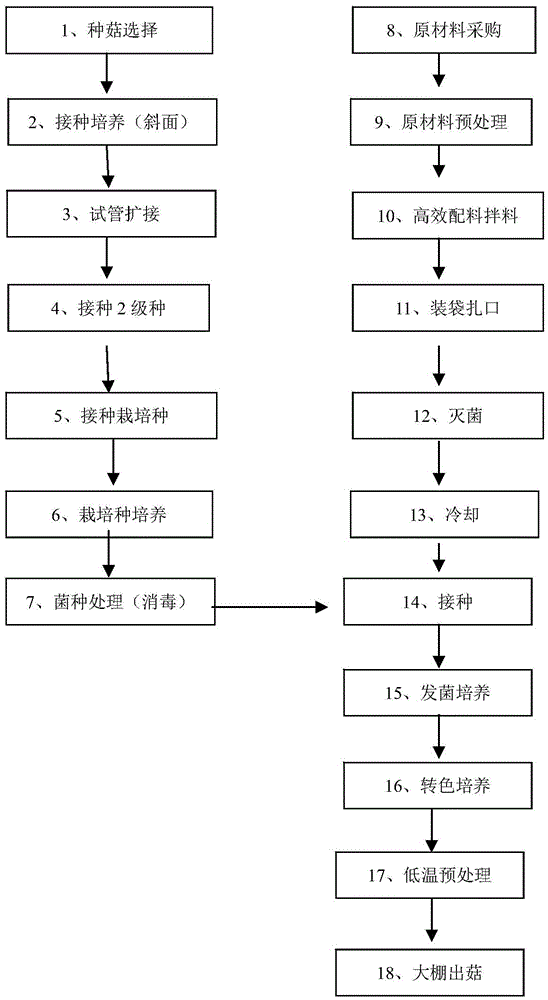

Image

Examples

Embodiment 1

[0033] Taking a certain spring greenhouse in Qingdao in early summer as an example, the mushroom compost is selected as 25 parts by weight of oak sawdust, 30 parts by weight of apple sawdust, 20 parts by weight of bran, and 5 parts by weight of corncob. , parts by weight of perlite are 5 parts, parts by weight of gypsum are 1 part, parts by weight of river mud are 0.8 parts, KH 2 PO 4 Parts by weight are 0.15 parts, MgSO 4 The parts by weight are 0.05 parts, adding water to adjust the moisture content of the mixture to 50%, wherein the particle diameter of the oak wood chips is 6 mm, and the particle size of the apple wood chips is 2 mm.

[0034] The specific operation is as follows:

[0035] 1. Strain treatment

[0036] (1) Choose fresh shiitake mushrooms with short stalks, many hair scales, and unopened umbrellas as seed mushrooms;

[0037] (2) Inoculation and cultivation: On the ultra-clean bench, tear the shiitake mushrooms from the stems, cut the mung bean-sized bacte...

Embodiment 2

[0054] Taking a certain spring greenhouse in Qingdao in summer as an example, the mushroom compost is selected as 27 parts by weight of oak sawdust, 35 parts by weight of apple sawdust, 25 parts by weight of bran, and 7 parts by weight of corncob. , parts by weight of perlite are 7 parts, parts by weight of gypsum are 3 parts, parts by weight of river mud are 0.9 parts, KH 2 PO 4 Parts by weight are 0.172 parts, MgSO 4 The parts by weight are 0.07 parts, and water is added to adjust the moisture content of the mixture to 55%, wherein, the particle diameter of oak wood chips is 8 mm, and the particle size of apple wood chips is 3 mm.

[0055] The specific operation is as follows:

[0056] The difference from Example 1 is that the culture material is mixed with water to adjust the water content to 55%, and the rest of the operations are the same as in Example 1. It was placed in the greenhouse on July 11, 2014. The temperature in the greenhouse was controlled at around 25°C d...

Embodiment 3

[0058] Taking a certain spring warming greenhouse in Qingdao at the end of summer as an example, the mushroom compost is selected as 30 parts by weight of oak sawdust, 40 parts by weight of apple sawdust, 30 parts by weight of bran, and 10 parts by weight of corncob. Parts, parts by weight of perlite are 10 parts, parts by weight of gypsum are 5 parts, parts by weight of river mud are 1 part, KH 2 PO 4 Parts by weight are 0.2 parts, MgSO 4 The parts by weight are 0.1 part, water is added to adjust the water content of the mixture to 0.58, wherein the particle size of oak wood chips is 10 mm, and the particle size of apple wood chips is 3 mm.

[0059] The specific operation is as follows:

[0060] The difference from Example 1 is that the culture material is mixed with water to adjust the water content to 58%, and the rest of the operations are the same as in Example 1. It was put into the greenhouse on September 20, 2014. The temperature in the greenhouse was controlled at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com