Porous material capable of removing total phosphorus in wastewater and preparation method of porous material

A porous material and wastewater technology, applied in chemical instruments and methods, other chemical processes, water/sewage treatment, etc., can solve the problems of complex operating conditions, large consumption of chemicals, and high operating costs, and achieve good chemical stability and use. Simple method and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A preparation method of a porous material applied to the removal of total phosphorus in wastewater comprises the following steps:

[0032] Preparation of porous material matrix: Weigh 5 kg of alumina, 1 kg of potassium feldspar, 50 kg of bentonite, 2 kg of quartz powder, 0.5 kg of calcite, 0.5 kg of talcum powder, and 2.5 kg of graphite powder, add water, balls, and dispersant , the dispersant is sodium tripolyphosphate, and their ratio is material: water: ball: dispersant = 1: 0.8: 2: 0.003, and then they are put into the ball mill tank together for 18 hours; Mesh sieve, pour it into a stainless steel tray, and then put it into an oven for drying; shape the dried mud powder into a ball through an extruder, put the ball into an oven for drying, and dry the water below 0.8%, and finally use it electric furnace firing;

Embodiment 2

[0034] Preparation of porous material matrix: Weigh and take 1 kg of CaO, 1 kg of alumina, 3 kg of potassium feldspar, 5 kg of bentonite, 3 kg of quartz powder, 1.5 kg of calcite, and 3.5 kg of graphite powder, then add water and balls, Their ratio is material: water: ball = 1:0.8:2, put them together into the ball mill tank for ball milling for 18 hours; pass the ball milled slurry through a 300-mesh screen, pour it into a stainless steel plate, and then put it into the oven together Carry out drying; the dried mud powder is rolled into balls by machinery, put the balls in an oven to dry, the dry moisture is less than 0.8%, and finally fired in an electric furnace. Thus, porous materials are synthesized. The specific surface of the porous material is 220m 2 / g, with an average pore size of 25nm.

[0035] The influent water of this project is the tail water discharged from a sewage treatment plant.

[0036] sewage type pH COD cr BOD 5 SS TP NH 3 -N ...

Embodiment 3

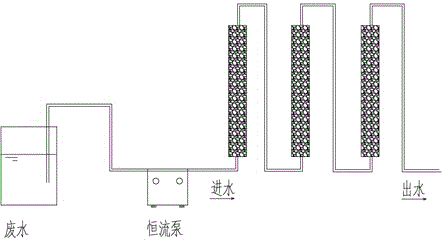

[0041] With embodiment 1, embodiment 2 and embodiment 2 materials are connected in sequence such as figure 1 , the filling quality of each material is 157g, 145g, 156g respectively, and it is filtered at a flow rate of 8ml / min. After filtering 500ml of tail water, 50ml is sampled to detect NH 3 -N and TP, experimental setup, the results are shown in Table 3.

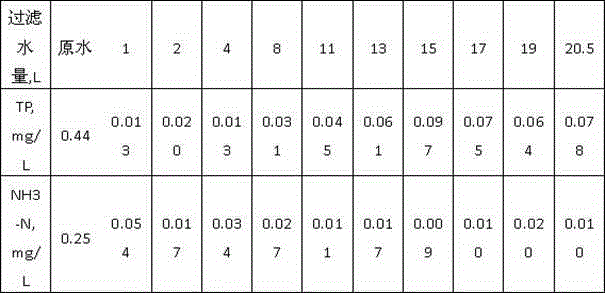

[0042] Table 3 Results of optimized combined phosphorus and ammonia nitrogen removal

[0043]

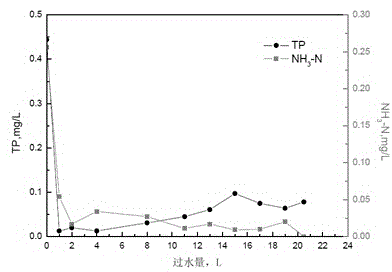

[0044] For Table 3 filtered water volume and TP and NH 3 -N, make a change curve, as attached figure 2 shown, from figure 2 It can be seen that under this optimized combination, the removal of total phosphorus and ammonia nitrogen in the tail water is very good. When the permeate volume reaches 20L, the concentrations of total phosphorus and ammonia nitrogen are 0.078mg / L and 0.010mg / L, respectively. It is far lower than the requirements for Class IV water bodies in the "Surface Water Environmental Quality Standard"...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com