Water jet and laser etching machine and method for ceramics

A technology of laser etching and water jet, which is applied in the direction of laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of affecting the surface processing quality of materials, severe thermal stress and microcracks of the recast layer, and achieve low cost, The effect of reducing the thickness of the recast layer and reducing the heat-affected zone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

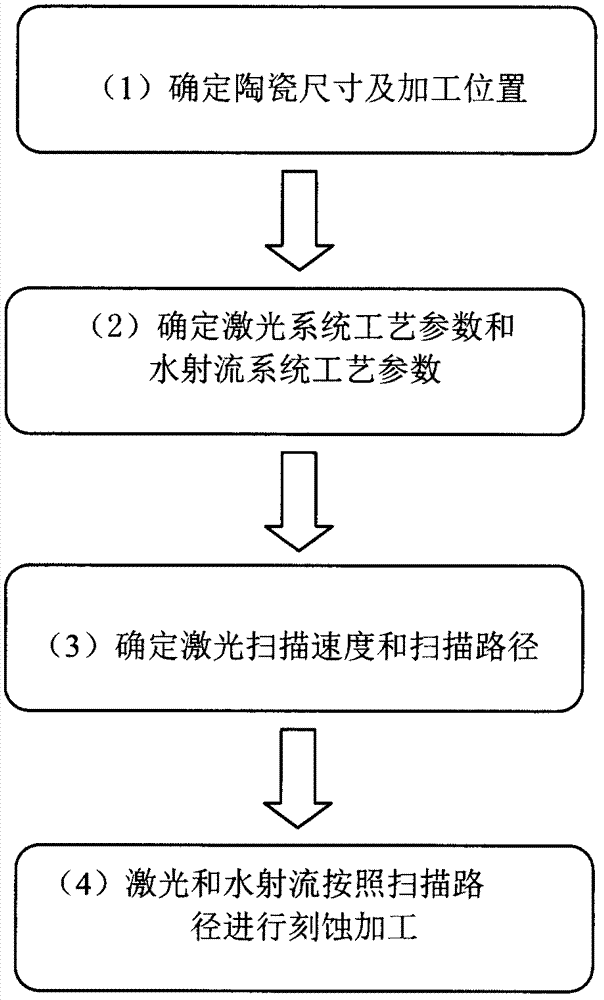

[0031] In order to show the present invention more clearly, the present invention will be further described below in conjunction with the accompanying drawings.

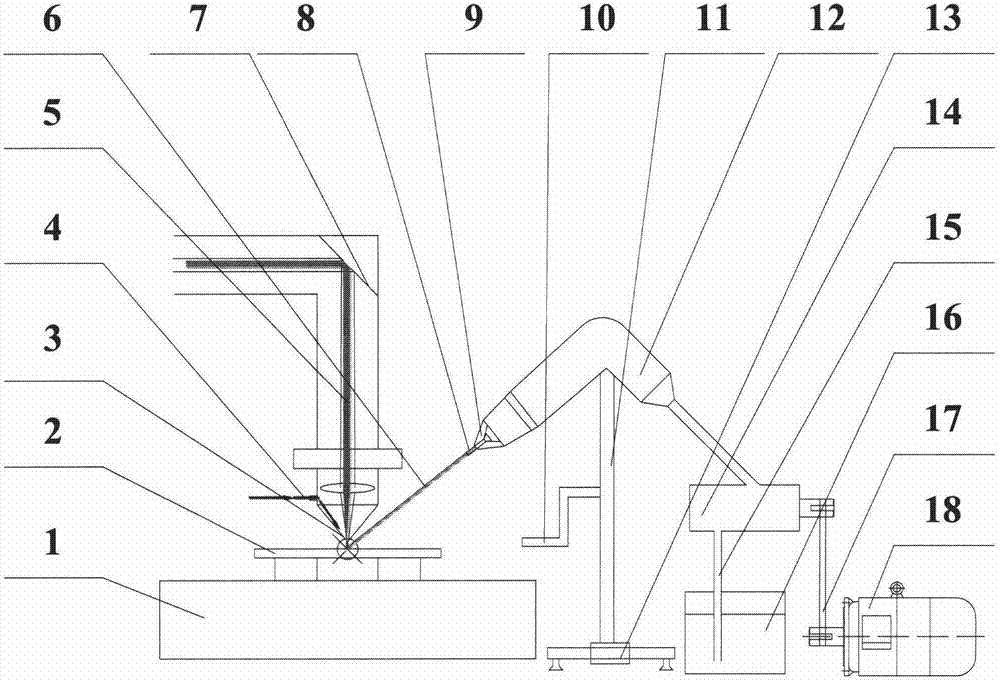

[0032] like figure 1 As shown, it includes a laser system and a water jet system. The laser system is the main body. The ablation effect of the laser beam (5) can etch corresponding grooves on the ceramic surface. The water jet system plays an auxiliary role. The water jet beam (6) The erosion effect effectively reduces the slag on the surface of the groove.

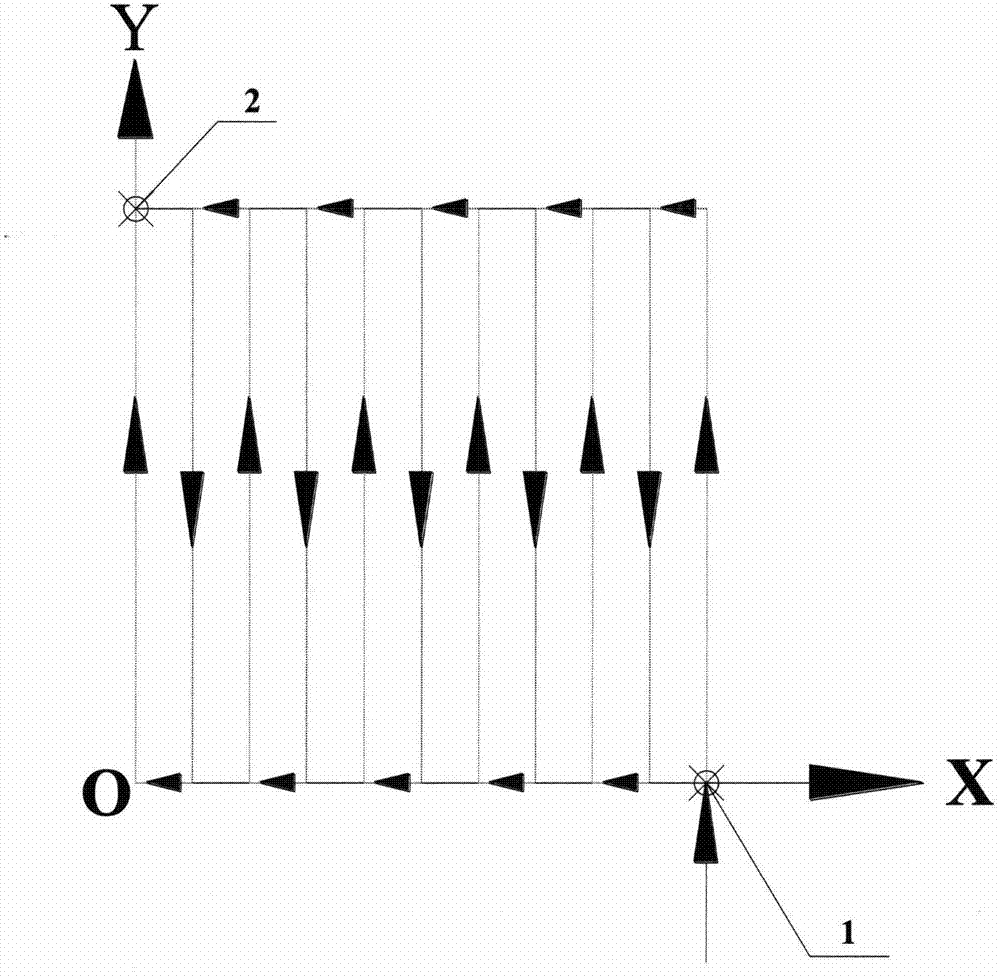

[0033] The pulsed laser current intensity of the laser system is 150+50A, the pulse width is 0.6+0.2ms, the pulse frequency is 30±10Hz, the scanning speed is 0.8±0.2mm / s, and the laser etching ceramic depth is nanometer level. The required laser system The process parameters cannot be too large.

[0034] The water jet system ejects the water jet stream (6) through the medical needle (8) installed on the nozzle (9). Guide rail (13) adjustment.

[0035] Turn ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com