Alfalfa seed obducens agent and production process thereof

A technology of seed pill coating agent and alfalfa, which is applied in application, organic fertilizer, nitrogen fertilizer, etc., can solve the problems of mutual antagonism between effective parts, and achieve significant production and application effects, reduce pollution, and save production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

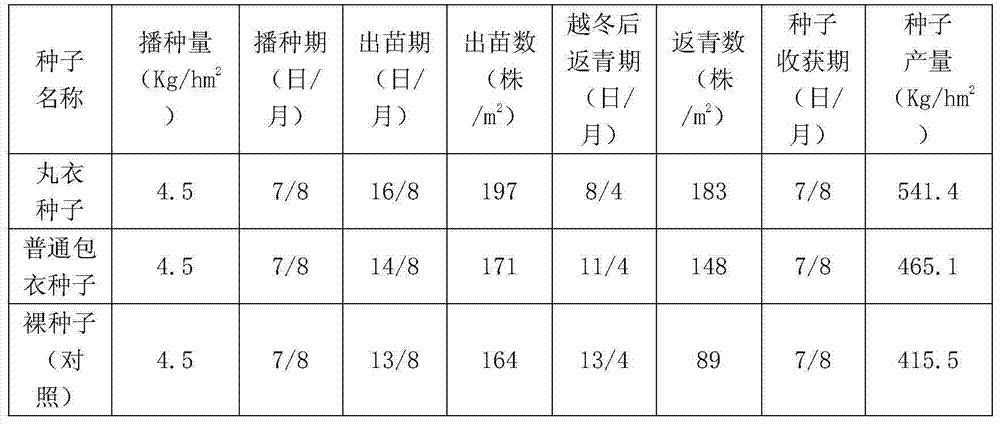

Embodiment 1

[0027] 1.1 The alfalfa seed coating of the present invention is made up of the following raw materials in percentage by weight: carboxymethyl cellulose 1.5%, alfalfa rhizobium 3%, biological humic acid 0.5%, urea 3%, potassium dihydrogen phosphate 0.2% , ammonium molybdate 0.7%, borax 0.1%, sulfur powder 6%, ferrous sulfate 0.15%, sodium polyacrylate 8%, indole butyric acid 0.01%, gibberellin 0.05%, lysacetic acid 0.01%, thiram 8.0 %, thiophanate-methyl 2.0%, and the balance is alfalfa seeds.

[0028] 1.2 The concrete steps of the production technology of alfalfa seed pill coating agent of the present invention are as follows:

[0029] (1) take raw materials by proportioning;

[0030] (2) Add alfalfa seeds to the seed coating machine, first spray the prepared carboxymethyl cellulose and continue to stir until the alfalfa seeds are moist, then add the Rhizobium alfalfa and continue to stir to check whether each seed is infected with bacteria, until the bacteria are uniform Th...

Embodiment 2

[0036] 2.1 The alfalfa seed pill coating agent of the present invention is made up of the following raw materials in weight percentage: carboxymethyl cellulose 5%, alfalfa rhizobium 0.5%, biological humic acid 7%, urea 0.2%, potassium dihydrogen phosphate 3% , ammonium molybdate 0.1%, borax 0.5%, sulfur powder 2%, ferrous sulfate 0.7%, sodium polyacrylate 5%, indole butyric acid 0.05%, gibberellin 0.01%, lysacetic acid 0.05%, thiram 1.0 %, thiophanate-methyl 8.5%, and the balance is alfalfa seeds.

[0037] 2.2 The production technology of alfalfa seed pill coating agent of the present invention

[0038] 1.2 with embodiment 1.

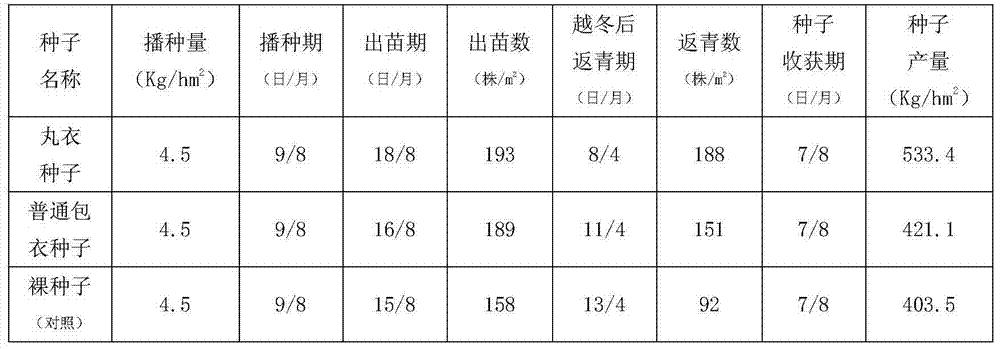

[0039] From 2007 to 2008, the test was carried out at the seed production base of Jiuquan Daye Seed Industry Company (Shangba Town, Suzhou District, Jiuquan City), and the results are shown in Table 2:

[0040] Table 207 Alfalfa Seed Pill Coating Test Investigation Form

[0041]

[0042] The test results show that the seeds coated with pellets are...

Embodiment 3

[0044] 3.1 The alfalfa seed coating of the present invention is made up of the following raw materials in percentage by weight: carboxymethyl cellulose 3%, alfalfa rhizobium 2%, biological humic acid 4%, urea 1.5%, potassium dihydrogen phosphate 1.5% , ammonium molybdate 0.4%, borax 0.3%, sulfur powder 4%, ferrous sulfate 0.5%, sodium polyacrylate 7%, indole butyric acid 0.03%, gibberellin 0.03%, lysacetic acid 0.03%, thiram 5 %, thiophanate-methyl 5%, and the balance is alfalfa seeds.

[0045] 3.2 The production technology of alfalfa seed pill coating agent of the present invention

[0046] 1.2 with embodiment 1.

[0047] From 2007 to 2008, the test was carried out at the seed production base of Jiuquan Daye Seed Industry Company (Shangba Town, Suzhou District, Jiuquan City), and the results are shown in Table 3:

[0048] Table 307 Alfalfa Seed Pill Coating Test Investigation Form

[0049]

[0050] The test results show that the seeds coated with pellets are better than...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com