Fabric coating agent, ultrathin windproof and moisture permeable ultraviolet resistant fabric and preparation method thereof

An anti-ultraviolet and coating agent technology, which is applied in the fields of fabric coating agent, anti-ultraviolet coating processing, windproof, moisture-permeable and anti-ultraviolet fabric and its preparation, can solve the problem of inability to play a good protective effect, anti-ultraviolet, and moisture permeability It does not have, cannot achieve ultra-thinness and other problems, and achieves the effects of enhanced anti-ultraviolet synergistic effect, strong hydrophilic and moisture-conducting effect, and excellent moisture permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Base fabric selection: 15D×15D380T polyester spinning peacock blue grey fabric 38g / m 2

[0041] Waterproof: Waterproofing agent FS-508A 2.5% (ie, 2.5g parts of waterproofing agent and 97.5 parts of water are mixed to form a finishing solution)

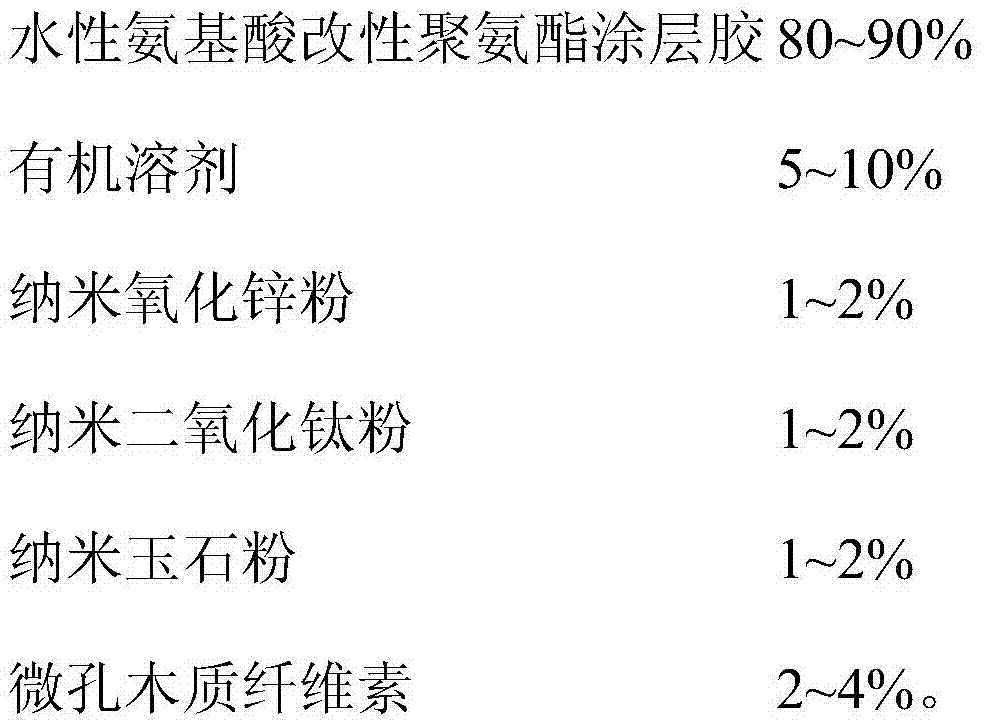

[0042] According to the mass percentage of each component of the fabric coating agent, the fabric coating agent includes:

[0043]

[0044] Water-based amino acid modified polyurethane coating glue FS-417 and water-repellent agent FS-508A are produced by Liaoning Star Fine Chemical Co., Ltd.; nano zinc oxide powder, nano titanium dioxide powder, nano jade powder, microporous lignocellulose (particle size 15μm≤d ≤30μm) are commercially available products.

[0045] The preparation method of the ultra-thin wind-proof, moisture-permeable and UV-resistant fabric includes:

[0046] Waterproof (two dipping and two rolling, baking temperature 170℃, drying time 50-60s);

[0047] Calendering (temperature 80℃, pressure 80T, base fabric traveling spe...

Embodiment 2

[0054] Base cloth selection: 20D×20D420T nylon GQiaogli yellow grey cloth 40g / m 2

[0055] Waterproof: Waterproofing agent TG-5802.0% (ie, 2.0g parts of waterproofing agent and 98.0 parts of water are mixed to form a finishing solution)

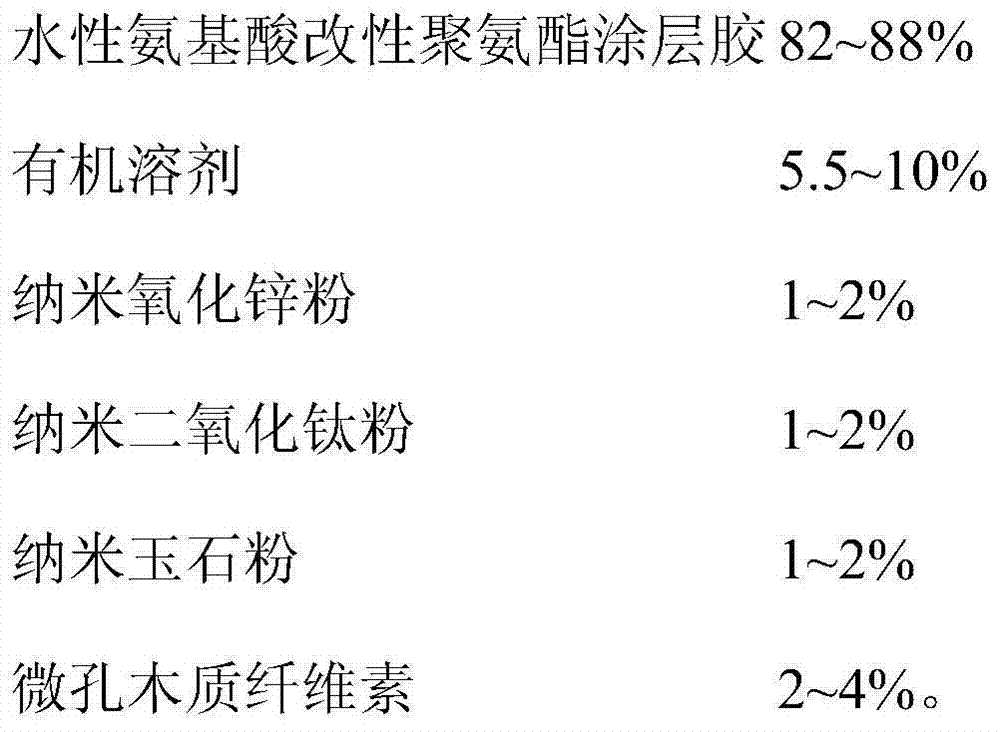

[0056] According to the mass percentage of each component of the fabric coating agent, the fabric coating agent includes:

[0057]

[0058] The preparation method of the ultra-thin wind-proof, moisture-permeable and UV-resistant fabric includes:

[0059] Waterproof (two dipping and two rolling, baking temperature 180℃, drying time 50~60s)

[0060] Calendering (temperature 80℃, pressure 80T, base fabric traveling speed 30m / min)

[0061] Coating fabric coating agent (sizing amount 6g / m 2 , The drying tunnel adopts a temperature gradient, the temperature gradient from the entrance to the exit of the drying tunnel is 150℃~155℃~160℃~165℃, and the drying time is 40~50s).

[0062] Index test

[0063] Table 320D×20D420T Nylon Gechogri Yellow Coating Before and Af...

Embodiment 3

[0068] Base fabric selection: 15D×15D380T polyester spinning peacock blue grey fabric 38g / m 2

[0069] Waterproof: Waterproof agent TG-5812.5% (that is, 2.5g parts of waterproofing agent and 97.5 parts of water are mixed to form a finishing solution)

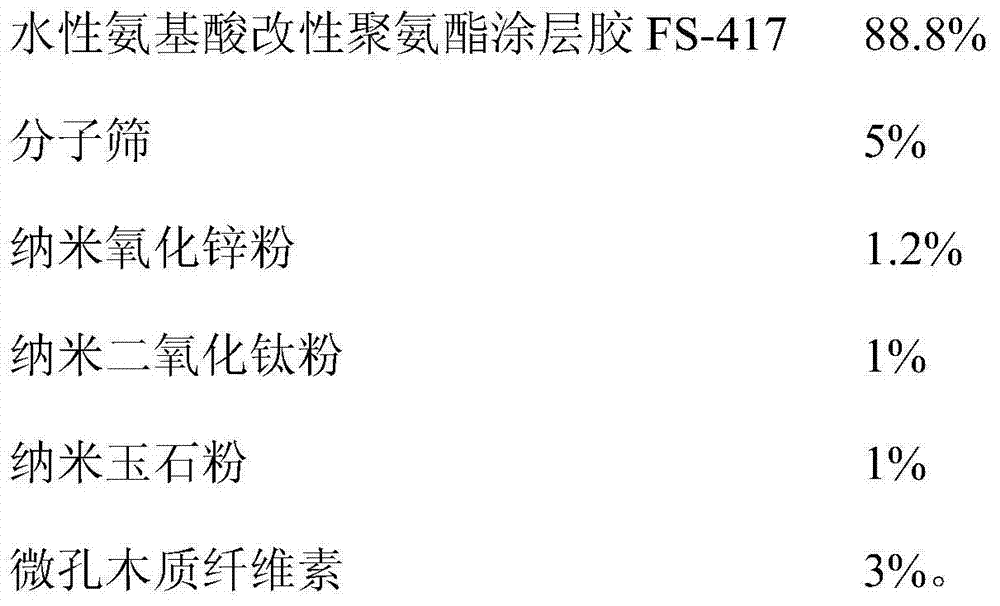

[0070] According to the mass percentage of each component of the fabric coating agent, the fabric coating agent includes:

[0071]

[0072] The water-based amino acid modified polyurethane coating glue FS-417 is produced by Liaoning Hengxing Fine Chemical Co., Ltd., and the waterproofing agent TG-581 is produced by Japan Daikin Industry Co., Ltd., nano zinc oxide powder, nano titanium dioxide powder, nano jade powder, microporous Lignocellulose is commercially available as a nanometer product.

[0073] The preparation method of the ultra-thin wind-proof, moisture-permeable and UV-resistant fabric includes:

[0074] Waterproof (two dipping and two rolling, baking temperature 170℃, drying time 50-60s);

[0075] Calendering (temperature 70...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com