A kind of LED fluorescent transparent polycarbonate grating and preparation method thereof

A polycarbonate and transparent technology, which is applied in the field of LED fluorescent transparent polycarbonate grating and its preparation, can solve the problem of decreased light transmittance of polycarbonate composition, difficulty in controlling the thickness and shape of phosphor coating, human eye irritation, etc. problems, to achieve the effect of improving glare and uneven light distribution, slowing down and avoiding deactivation, and eliminating the need for processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

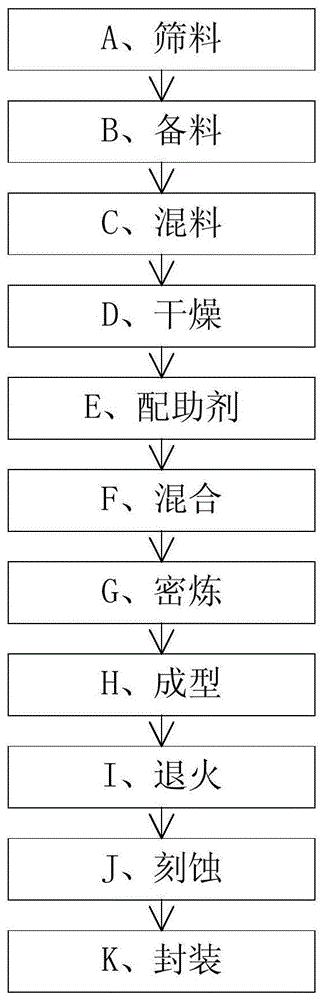

[0035] refer to figure 1 , a method for preparing an LED fluorescent transparent polycarbonate grating, comprising the following steps:

[0036] A, sieve material, screen out the polycarbonate powder that particle diameter is 30-90um with 150 purpose experiments;

[0037] B, prepare materials, take phosphor powder by component mass ratio, particle diameter is 30-90um polycarbonate;

[0038] C. Mixing, put the polycarbonate powder and fluorescent powder into a variable frequency planetary ball mill for mixing, the speed of the variable frequency planetary ball mill is 160-250r / min, and the mixing time is 1-5h to obtain a compound;

[0039] D, drying, put the mixed material into a vacuum constant temperature drying oven to dry, the drying temperature is 50-120 ℃, and the drying time is 3-20h, to obtain a dried mixed material, the maximum moisture content of the polycarbonate powder is less than 0.020%;

[0040] E, compounding auxiliary agent, weigh antioxidant and light diffus...

Embodiment 1

[0060] Embodiment 1: comprise the following steps:

[0061] A, sieve material, screen out the polycarbonate powder that particle diameter is 30-90um with 150 purpose experiments;

[0062] B, prepare materials, weigh the phosphor powder according to the mass ratio of the first group of components in Table 1, and the particle size is 30-90um polycarbonate; wherein the phosphor powder only weighs the yellow phosphor powder;

[0063] C. Mixing, put the polycarbonate powder and fluorescent powder into a variable frequency planetary ball mill for mixing, the speed of the variable frequency planetary ball mill is 160-250r / min, and the mixing time is 1-5h to obtain a compound;

[0064] D, drying, put the mixed material into a vacuum constant temperature drying oven to dry, the drying temperature is 50-120 ℃, and the drying time is 3-20h, to obtain a dried mixed material, the maximum moisture content of the polycarbonate powder is less than 0.020%;

[0065] E, adjuvant, weigh antioxid...

Embodiment 2-7

[0073] Embodiment 2-7, the step flow is the same as that of embodiment 1, and the data used in the steps B and E are according to the data of the 2-7 groups in Table 1 respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com