Texture pretreatment liquid for diamond wire cutting polycrystalline silicon wafer, texturing pretreatment method, texturing pretreatment silicon wafer and application thereof

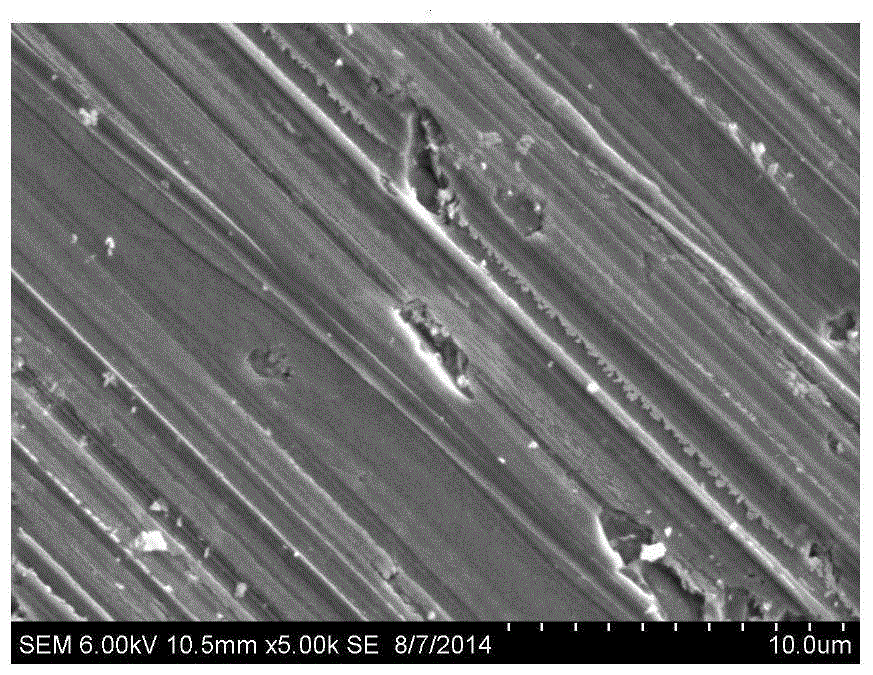

A diamond wire cutting, polycrystalline silicon wafer technology, applied in the directions of post-processing, post-processing details, chemical instruments and methods, etc., can solve the problems of too shallow damage layer on the surface of the silicon wafer, dense surface traces, etc., and achieve a simple and good ratio. Compatibility, effect of short processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] A kind of texturing pretreatment method of diamond wire cut polysilicon chip, comprises the steps:

[0059] (1) Preparation of velvet pretreatment liquid:

[0060] Mixing nitric acid, hydrofluoric acid, acetic acid and water to obtain a texturing pretreatment solution, wherein the volume ratio of nitric acid, hydrofluoric acid, acetic acid and water is 10-15:1-5:2-6:10-30;

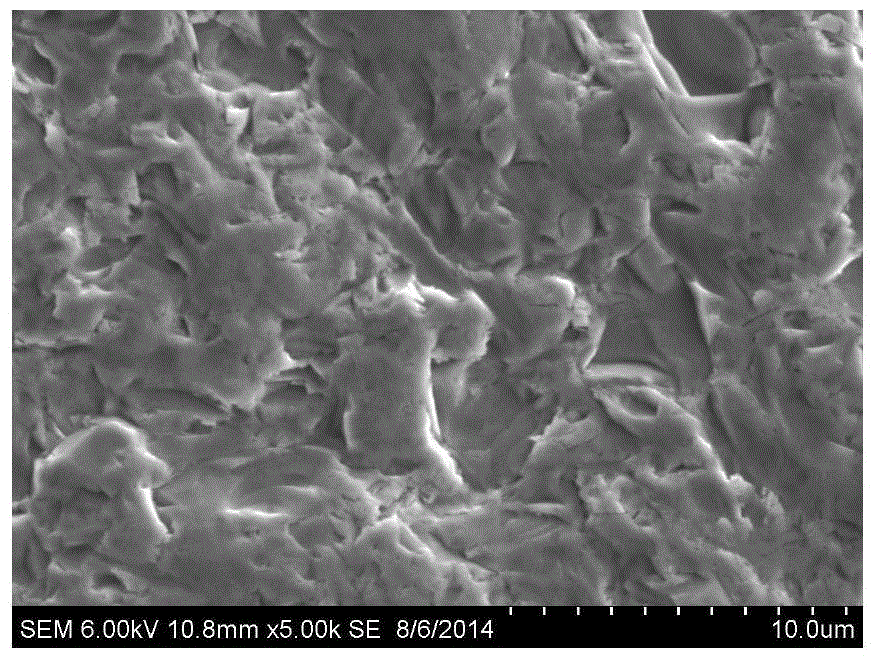

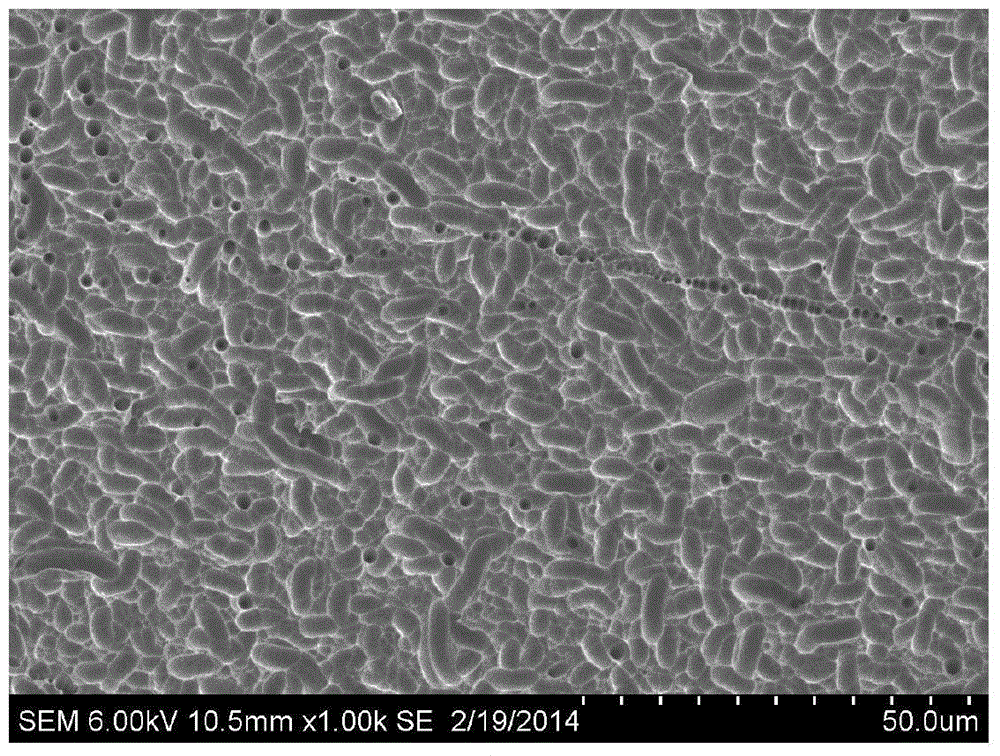

[0061] (2) Preparation of porous silicon structure:

[0062] Take the diamond wire-cut polycrystalline silicon wafer and clean it with a concentration of 10% dilute HF solution to remove the oil stain and oxide layer on the surface of the silicon wafer, and then place it in the texturing pretreatment solution for pretreatment. The treatment temperature is At room temperature, the treatment time is 5 minutes to obtain a polysilicon wafer with a porous structure, that is, a pretreated polysilicon wafer for texturing.

[0063] Get the textured pretreated polysilicon wafer obtained by the above pretre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com