Electric melting forming method of metal component

A metal component and electrofusion technology, which is applied in the field of metal component electrofusion forming, achieves the effects of no macro segregation, improved mechanical properties, and improved plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

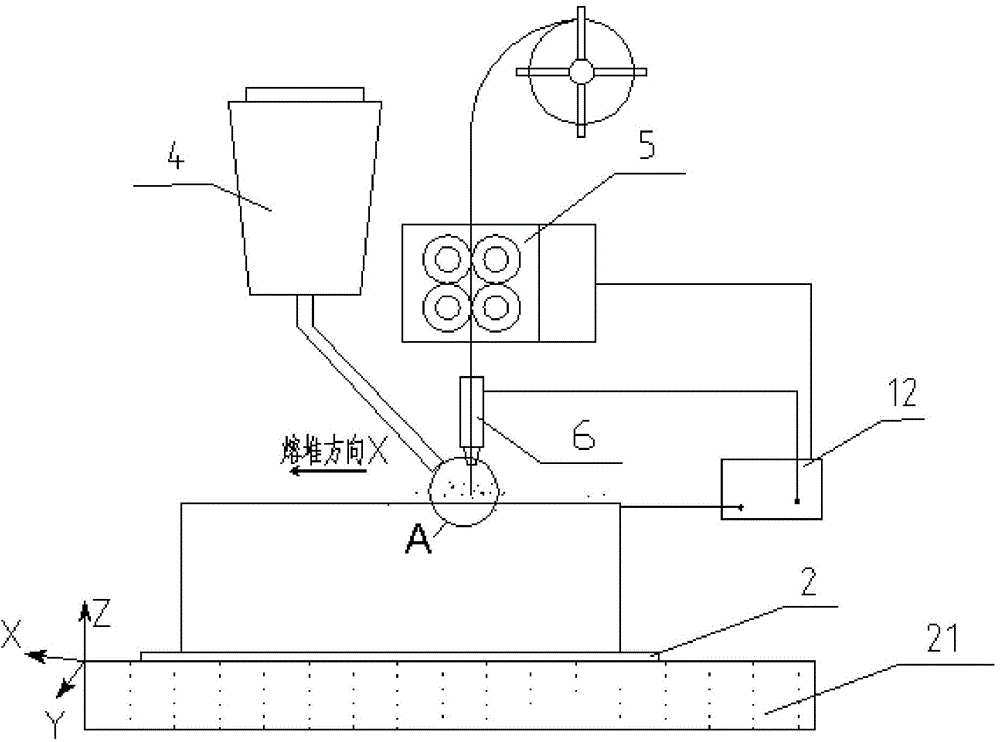

[0039] Horizontal production of rotary cylinder. This example describes the process of making a cylinder by horizontal electrofusion forming. The material is ordinary low-carbon steel. The equipment used includes:

[0040] (1) Rotary support table; (2) Electrofusion power supply; (3) Electrofusion head; (4) Automatic wire feeding device; (5) Automatic auxiliary material conveying and auxiliary material automatic recovery device; (6) Heating device; (7) Cooling device; (8) substrate; (9) control device (computer).

[0041] figure 2 It is a schematic explanatory diagram for showing the electrofusion forming method of this embodiment, and devices such as a power supply and an automatic wire feeding device are omitted in the figure. Such as figure 2 As shown, select common low-carbon steel raw material wire material 101, diameter 4mm, 19 electrofusion heads 401, the electrofusion power supply is a DC power supply, the electrofusion head 401 is connected to the negative pole o...

Embodiment 2

[0053] Vertical production of rotary body. Adopt a kind of metal member electrofusion forming method vertical growth to make a cylindrical metal member, the equipment used in this embodiment includes,

[0054] (1) Rotary support table; (2) Electrofusion power supply; (3) Electrofusion head; (4) Automatic wire feeding device; (5) Automatic auxiliary material conveying and auxiliary material automatic recovery device; (6) Blocking auxiliary material device; (7) ) heating device; (8) cooling device; (9) substrate; (10) control device.

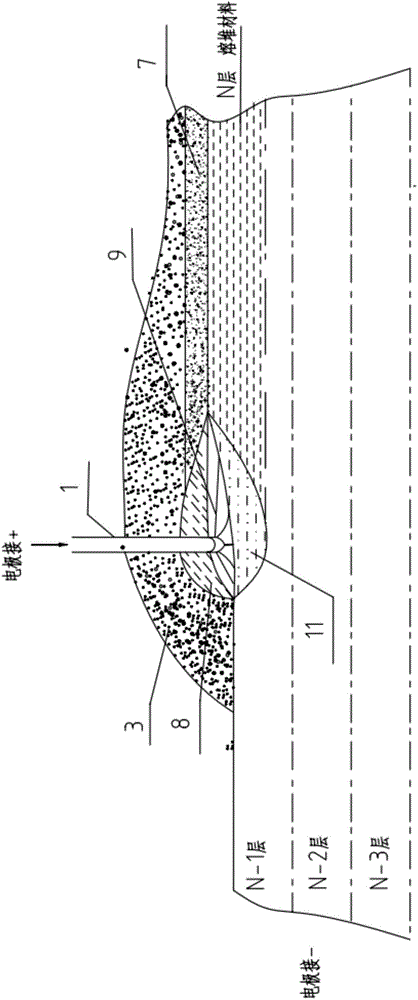

[0055] image 3 It is a schematic explanatory diagram showing the electrofusion forming method of this embodiment, and devices such as a rotary support table and a power supply are omitted in the figure. Such as image 3 As shown, choose ordinary low-carbon steel raw material wire, diameter 5mm, special auxiliary materials, an electric fusion head 602, the electric fusion power supply is a DC power supply, the electric fusion head is connected ...

Embodiment 3

[0066] Production of special-shaped workpieces. H08A ordinary low-carbon steel wire is selected, and a metal member electrofusion forming method is used to vertically grow the head metal member. The equipment used in this embodiment includes:

[0067] (1) Rotary support table; (2) Electrofusion power supply; (3) Electrofusion head; (4) Automatic wire feeding device; (5) Automatic auxiliary material conveying and auxiliary material automatic recovery device; (6) Blocking auxiliary material device; (7) ) heating device; (8) cooling device; (9) substrate; (10) control device.

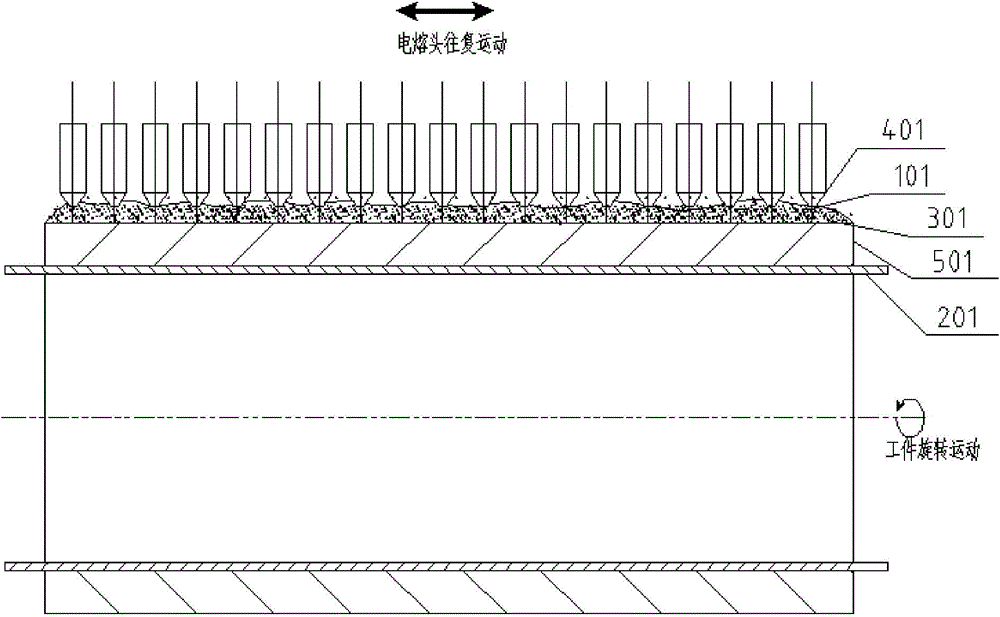

[0068] Figure 4 It is a schematic explanatory diagram showing the electrofusion forming method of this embodiment, and the equipment is omitted in the figure for simplification. The selected parameters are: diameter of wire rod is 5mm, auxiliary material is 30% Fe powder added to standard melting flux SJ101, setting electric melting current is 900A, electric melting voltage is 40V, electric fusion head ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com