A kind of high hydroxyl fluorocarbon copolymer coating and its application

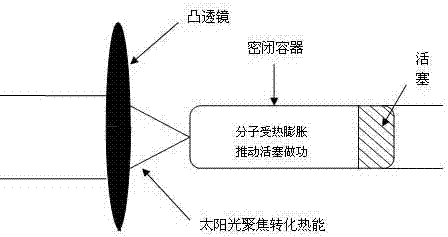

A high-hydroxyl fluorocarbon copolymer and coating technology, applied in polyurea/polyurethane coatings, coatings, instruments, etc., can solve the problems of being easily polluted by dust and other particles, power generation efficiency decline, and the feasibility of convex lenses is not high. Effect of dust prevention, reduction of unevenness, effect of solving self-cleaning problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] (1) Preparation of paint: Add 600g of chlorotrifluoroethylene copolymer (hydroxyl value 135 mgKOH / g) to the container, then stir at high speed, maintain the speed of 1500r / min, add 30g diluent methyl ethyl ketone, 90g ethyl acetate, ring After 105g of hexanone, add 9g of defoamer BYK110, 6g of adhesion promoter Z-6040, 26g of leveling agent EFKA3777, ultraviolet absorber UV-912g, 16g of antistatic agent MONENG-6002, and 14g of anti-sagging agent AT723. Finally, 20 g of diluent methyl ethyl ketone, 45 g of ethyl acetate and 50 g of cyclohexanone were added. Add 300g hardener HDI. See Table 1 for specific ingredients.

[0042] (2) Preparation of coating: Use 30cm×15cm glass as the substrate, use water and butyl acetate to clean the surface oil and impurities and dry. Use 517 spray gun nozzle, spray air pressure is 0.2~0.3MPa, when spraying, the nozzle is 25~30cm away from the substrate. The high-hydroxy fluorocarbon coating is sprayed on the substrate by 10μm, and after 3...

Embodiment 2

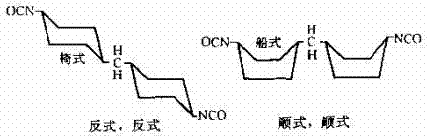

[0046] (1) Preparation of paint: Add 605g of chlorotrifluoroethylene copolymer (hydroxyl value 136mgKOH / g) to the container and stir at high speed, keep 1500r / min, add 57g of diluent xylene, 70g of butyl acetate, and methyl isobutyl ketone After 80g, add 6g defoamer BYK141 and TEGO substrate wetting agent ® Wet270 8g, adhesion promoter Z-6020 9g, leveling agent EFKA3600 15g, antistatic agent HA-66 7g, finally add diluent xylene 40g, butyl acetate 44g, methyl isobutyl ketone 59g. Add 450g of curing agent IPDI. See Table 1 for specific ingredients.

[0047] (2) Preparation of coating: Use 30cm×15cm glass as the substrate, use water and butyl acetate to clean the surface oil and impurities and dry. Use the nozzle of the 517 spray gun, the spraying air pressure is 0.4~0.5MPa, and the nozzle is 20~25cm away from the substrate during spraying. Spray 10μm of high-hydroxy fluorocarbon hydrophobic dustproof coating on the substrate, and then continue to spray 20-30μm on the substrate ...

Embodiment 3

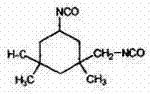

[0051] (1) Preparation of paint: Add 620g of chlorotrifluoroethylene copolymer (hydroxyl value 145 mgKOH / g) to the container, stir at high speed, keep 1500r / min, add 160g of diluent ethylene glycol ethyl ether acetate, add defoamer separately BYK066N12g, substrate wetting agent TEGO ® WetKL245 16g, adhesion promoter Z-6040 12g, leveling agent BYK310 30g, ultraviolet absorber HTUV120 18g, antistatic agent HDC-308 12g, anti-sagging agent BYK430 10g, and finally add diluent diluent glycol ethyl ether acetic acid 100g of ester. Add curing agent HMDI 200g, HDI 200g. See Table 1 for specific ingredients.

[0052] (2) Preparation of coating: Use 30cm×15cm glass as the substrate, use water and butyl acetate to clean the surface oil and impurities and dry. Use 517 spray gun nozzle, spray air pressure is 0.3~0.4MPa, when spraying, the nozzle is 23~28cm away from the substrate. The high-hydroxy fluorocarbon hydrophobic dust-proof coating is sprayed on the substrate for 10μm, after 50s,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com