A kind of anti-pid packaging adhesive film for photovoltaic cells

A technology for encapsulating adhesive films and photovoltaic cells, applied in photovoltaic power generation, circuits, adhesives, etc., can solve problems that are not conducive to the aging resistance of encapsulating adhesive films, the decline in polyolefin insulation performance, and the large amount of silane coupling agent volatilization, etc., to achieve excellent performance Anti-PID performance, avoid PID effect, improve the effect of aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0035] The polyolefin resins adopted in the following examples are all purchased from American Dow Company or American DuPont Company. The melt index under the conditions of 190° C. and 2.16 kg load is 15 to 35 grams / 10 minutes, and the melting point measured by differential scanning calorimetry is It is 60-100°C, and the Vicat softening point is greater than 45°C.

[0036] Preparation of anti-PID packaging film for photovoltaic cells

[0037]Add clathrate polysilsesquioxane, peroxide crosslinking agent, co-crosslinking agent, light stabilizer, and ultraviolet light absorber to polyolefin resin, mix all raw materials evenly, and melt them in a single-screw extruder Extruded, then cast, cooled, coiled and other processes to finally obtain the encapsulation film.

[0038] Preparation of Photovoltaic Cell Modules

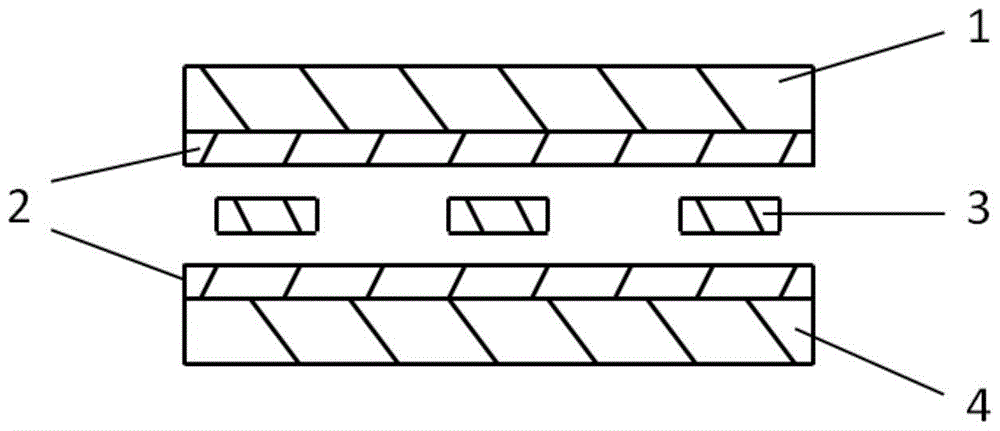

[0039] Use the encapsulation adhesive film of embodiment to prepare photovoltaic cell assembly, such as figure 1 As shown, the upper layer is tempered glass, the mi...

Embodiment 1

[0041] Add 10 parts of chlorine-based clathrate polysilsesquioxane, 2 parts of peroxide crosslinking agent bis(tert-butyl cumene peroxide) (Akzo Nobel, Perkadox 14s) in 100 parts (parts by mass) of polyolefin resin -f1), 0.5 part of co-crosslinking agent trimethylol propyl trimethacrylate (Sartomer, SR351), 0.1 part of UV absorber 2-hydroxyl-4-n-octyloxybenzophenone and 0.1 part of light stabilizer bis(2,2,6,6-tetramethyl-4-piperidinyl) sebacate, mix all raw materials evenly, put them into a single-screw extruder to melt and extrude, and then flow through Stretching, cooling, pulling, coiling and other processes to obtain packaging film A1, the weight of the film (the quality of the film whose length and width are 10cm×10cm) is 4g.

[0042] The resulting encapsulation film is prepared into a photovoltaic cell assembly, such as figure 1 As shown, the upper layer is a glass substrate 1 with a thickness of 3 mm, the middle layer is a battery sheet 3 , the lower layer is a fluori...

Embodiment 2

[0044] Add 15 parts of ethoxyl clathrate polysilsesquioxane, 1.5 parts of peroxide crosslinking agent 2,5-dimethyl-2,5-bis(tert-butyl) to 100 parts by mass of polyolefin resin Peroxide) hexane (AkzoNobel, TRIGONOX 101), 0.55 part of cross-linking agent trimethylolpropyl trimethacrylate (Sartomer, SR351), 0.15 part of ultraviolet light absorber 2-hydroxyl-4 -n-octyloxybenzophenone and 0.15 parts of light stabilizer bis(2,2,6,6-tetramethyl-4-piperidinyl) sebacate, mix all raw materials evenly, add to single screw extruder Melting and extruding in the machine, and then through casting, cooling, pulling, coiling and other processes, the encapsulation film A2 is obtained.

[0045] The resulting encapsulation film is prepared into a photovoltaic cell assembly, such as figure 1 As shown, the upper layer is a glass substrate 1 with a thickness of 3 mm, the middle layer is a battery sheet 3 , the lower layer is a fluorine-containing material back plate 4 with a thickness of 0.33 mm, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com