A kind of method and application of chelating functionalized magnetic polyvinyl alcohol microspheres

A polyvinyl alcohol microsphere and functionalization technology, which is applied in the direction of magnetism of organic materials/organic magnetic materials, preparation of microspheres, preparation of microcapsules, etc., to achieve rapid separation and recovery, obvious effect and mild conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The preparation method of ferroferric oxide magnetic particles is chemical co-precipitation method (see: Lu, A.-H.; Salabas, E. L.; Schüth, F., Magnetic Nanoparticles: Synthesis, Protection, Functionalization, and Application. Angewandte Chemie International Edition 2007,46 (8), 1222-1244.);

[0039] Mix ferrous sulfate heptahydrate and ferric chloride hexahydrate into a three-necked flask, add ammonia water into a dropping funnel under nitrogen at constant temperature in a water bath, adjust the pH to alkaline, stir vigorously, wash repeatedly with distilled water, vacuum dry, and grind.

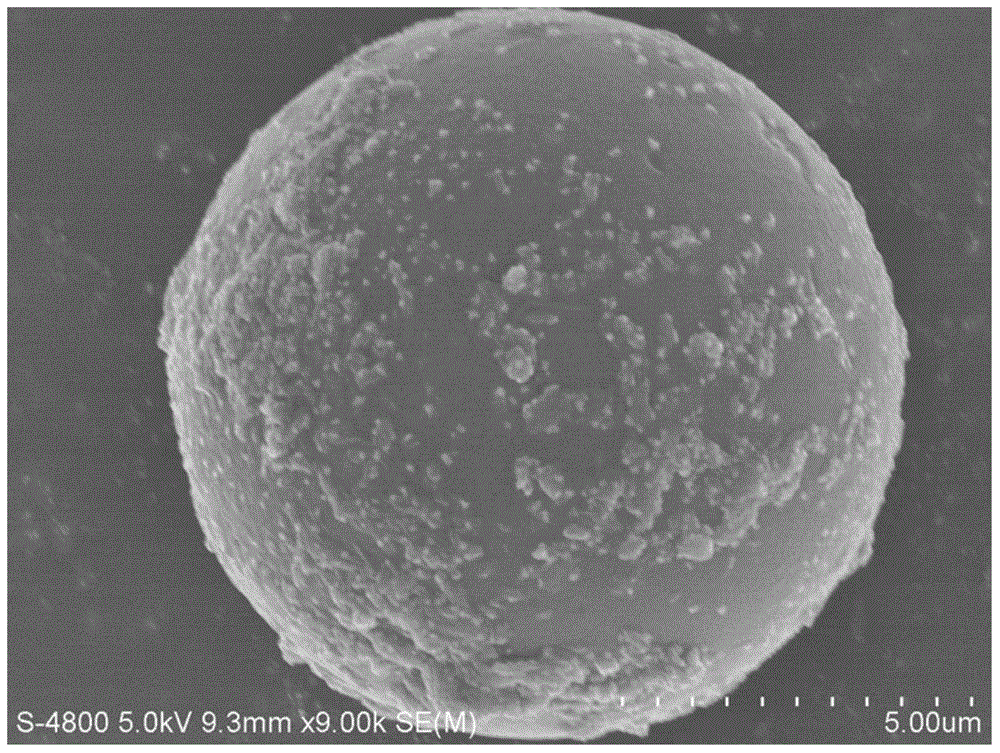

[0040] The preparation method of the magnetic polyvinyl alcohol microspheres is a reverse-phase suspension cross-linking method, and the particle size of the obtained magnetic polyvinyl alcohol microspheres is 5-50 μm (see: Shi Hanchang; Bai Xue; Wang Qing; Li Bing. Immobilized Laccase Microsphere carrier and its preparation method and application. Invention patent application num...

Embodiment 1

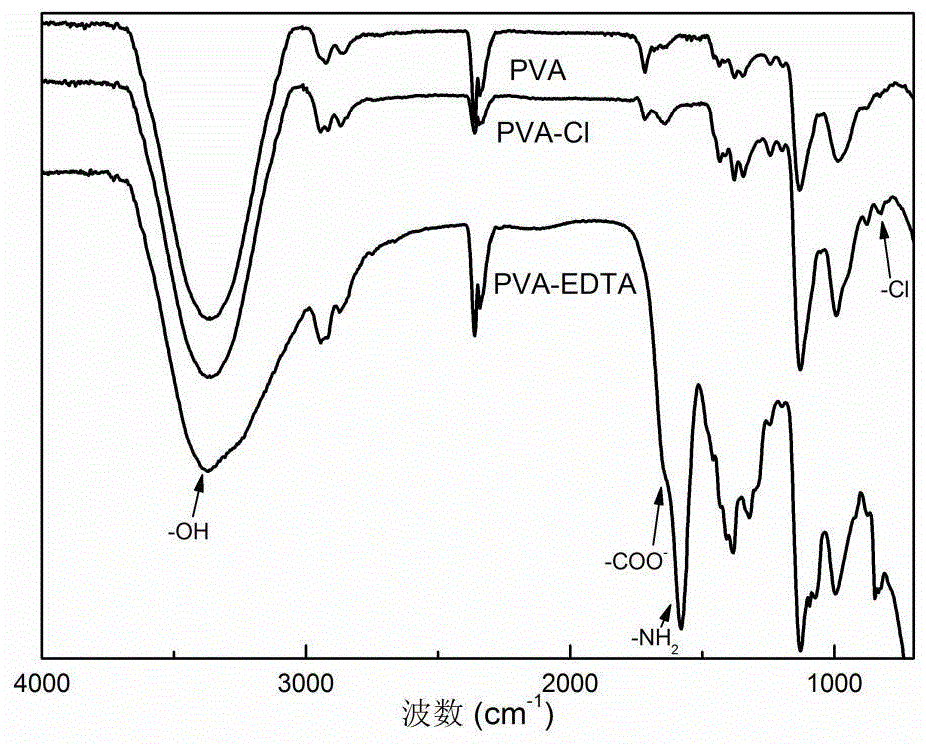

[0041] Embodiment 1, a kind of functionalization of magnetic polyvinyl alcohol microspheres

[0042] Dissolve 4g of polyvinyl alcohol (PVA) (1799) and 0.4g of ferroferric oxide magnetic particles in 40mL of water, stir mechanically in a boiling water bath for 1 hour, remove from the boiling water bath, wait for the reaction to cool to 60°C, add 80mL of liquid paraffin , stirred for 2h to form microspheres, then added 2mL of 1mol·L -1 hydrochloric acid solution and 4mL glutaraldehyde solution at a rotation speed of 500rpm (the radius of the stirring paddle is 2cm), after stirring for 30min, centrifuge at a rotation speed of 4000rpm (the radius of the centrifuge is 13.5cm) for 3min to separate the microspheres and wash them with petroleum ether for 3 times, and then vacuum-dried for 48 hours to obtain a brown powdery solid, that is, magnetic polyvinyl alcohol microspheres, with a particle size of 5-50 μm.

[0043] Take 2g of the above-prepared magnetic polyvinyl alcohol microsp...

Embodiment 2

[0047] Embodiment 2, a kind of functionalization of magnetic polyvinyl alcohol microspheres

[0048] Take 2g of the magnetic polyvinyl alcohol microspheres prepared in Example 1 and 20mL of epichlorohydrin, and add them to 200mL of hydrochloric acid at pH=5. After stirring for 5 hours in a water bath at 100° C. at a rotational speed of 2000 rpm, it was washed with distilled water for 3 times, and then vacuum-dried for 48 hours to obtain chlorinated magnetic polyethylene microspheres.

[0049] Then take 1 g of the chlorinated magnetic polyethylene microsphere solid powder obtained above and put it in 50 mL 1,4-dioxane to expand for 5 h, pour it into a three-necked flask, and then add 5 g of sodium hydroxide, 0.5 g of tetrabutyl bromide ammonium chloride, quickly pour 50mL of ethylenediamine. Heat it in a water bath to 100°C, keep stirring at 2000rmp for 10h, filter with distilled water, wash with petroleum ether three times, and dry in vacuum for 48h to obtain aminated magneti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com