Method for recycling and reusing waste hydrocracking catalyst

A hydrocracking and catalyst technology, applied in catalyst regeneration/reactivation, physical/chemical process catalysts, molecular sieve catalysts, etc., can solve the problems of low recycling rate, high pollution, etc., and achieve simple process, environmental protection and recycling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

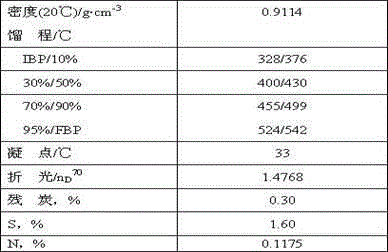

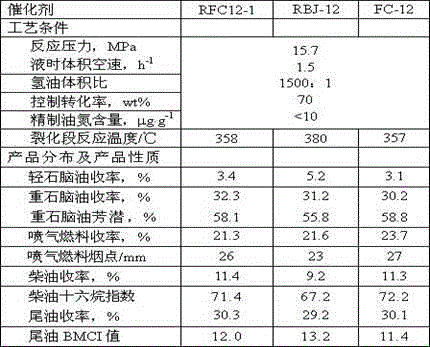

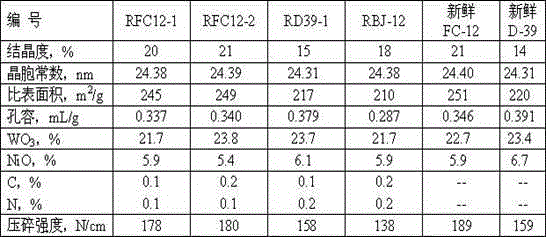

Embodiment 1

[0021] Take the FC-12 flexible hydrocracking catalyst (regenerated twice, with a total service life of 9 years) that has completed the service life of the industry, grind it into powder, and sieve it with a 200-mesh standard sieve. Then the catalyst powder was placed in a muffle furnace, and a nitrogen-oxygen mixture with an oxygen content of 2.0% was passed into the muffle furnace, and calcined at 460°C for 6h. Put 200g of roasted powder into an alkaline buffer solution of sodium carbonate and sodium hydroxide with a pH value of 12 for beating, the solid-to-liquid ratio is 1:4, the beating temperature is 75°C, the time is 60min, the solid-liquid separation is carried out, and the filter is washed with 70°C distilled water. Cake until neutral, and dry at 120°C for 6 hours; put 400g of the above dry powder into a roller compactor, add 4g / 100mL dilute nitric acid solution, and scallop powder, etc., and grind it into a paste shape, extruding it into a shape with a diameter of 1.5 ...

Embodiment 2

[0023] The buffer solution of example 1 is replaced by ammonium nitrate and ammoniacal liquor, the pH value is adjusted to 11.0, the solid-to-liquid ratio is 1:6, and the modified Y-1 molecular sieve (unit cell constant 24.40, crystallinity 90%) is added in the rolling process ), 28.0g tungstic acid and 20.0g nickel nitrate, other preparation methods are the same as in Example 1, and the obtained catalyst number is RFC12-2.

Embodiment 3

[0025] Replace the one in Example 1 with high and medium-sized industrial waste catalyst D-39, replace the buffer solution with ammonium carbonate and ammonia water, adjust the pH value to 12.0, the solid-to-liquid ratio is 1:5, the beating temperature is 65°C, the beating time is 120min, and the rolling process Add 16.0g of modified Y-2 molecular sieve (unit cell constant 24.30, crystallinity 95%), 28.0g tungstic acid and 20.0g nickel nitrate, other preparation methods are the same as in Example 1, and the catalyst number is RD39-1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com