Nanometer core shell structure thermite and preparation method thereof

A core-shell structure, thermite technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems affecting thermal performance indicators, particle crystal form damage, difficult aluminum and oxide uniformity Problems such as compounding or mixing, to achieve the effect of improving uniformity and integrity, improving thermal performance indicators, and facilitating uniform suspension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

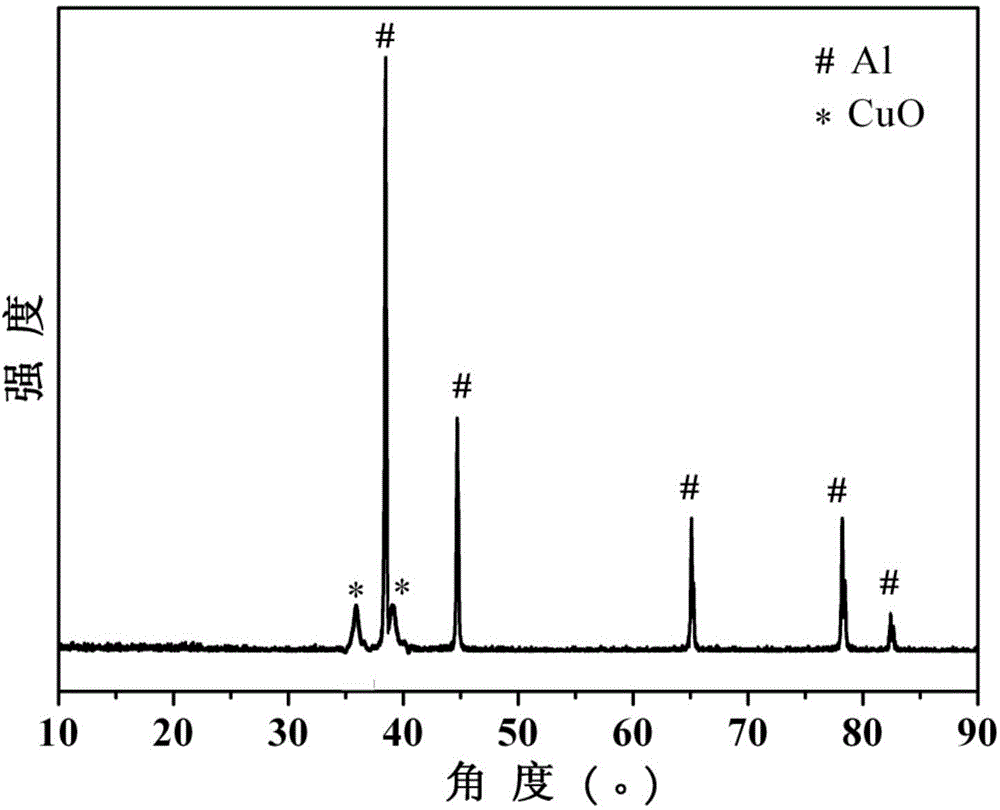

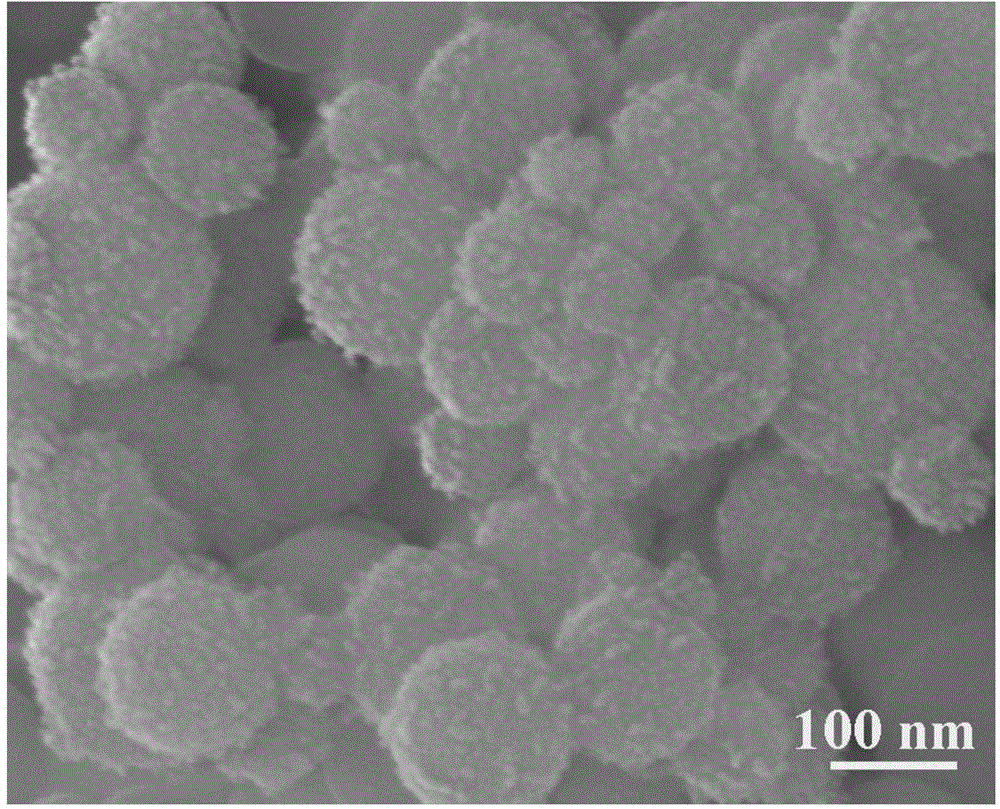

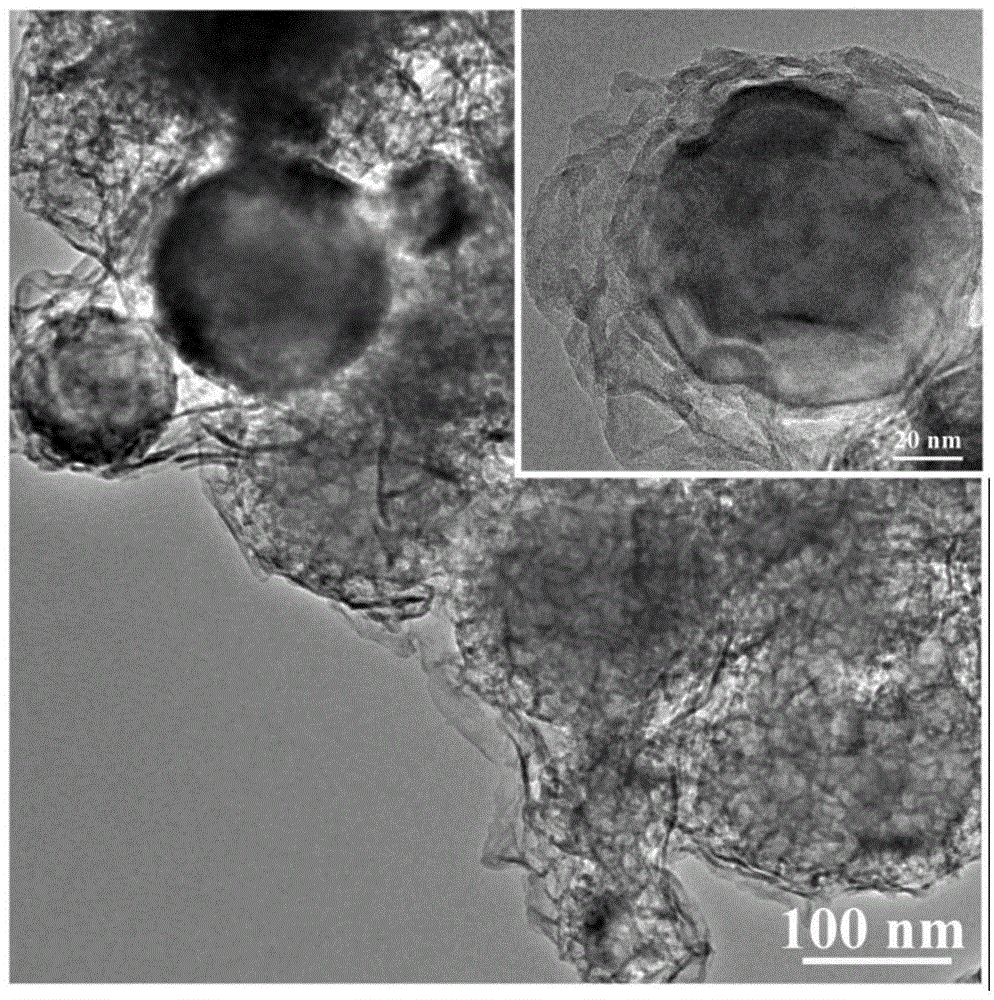

Embodiment 1

[0027] Fully mix 1,4-butanediol and deionized water according to the volume ratio of 1:1, and ultrasonicate the above solution for 0.5 hours to form a colorless and clear mixed solvent. Accurately measure 50 mL of the above mixed solvent, and then add 0.01mol of CuCl 2 4H 2 Dissolve O in the above solution for use; Accurately weigh 0.01 mol of nanoscale Al powder according to the Cu / Al molar ratio of 3:2, disperse it in the above copper salt solution, and ultrasonicate for 0.5 hours to form a stable suspension The solution was transferred to a 500mL three-necked flask, placed in an ice-salt bath, and stirred for 10 minutes; 50mL of a hydrazine hydrate solution with a concentration of 0.1mol / L was prepared with deionized water, and added dropwise to the three-necked flask while stirring. In the bottle, after the dropwise addition, crystallize at 60°C for 3 hours. The whole reaction process does not need to be protected by an inert atmosphere, and the H generated by the reactio...

Embodiment 2

[0029] Fully mix ethylene glycol and deionized water according to the ratio of volume ratio of 10:1, ultrasonicate the above solution for 0.5 hours to form a colorless and clear mixed solvent, accurately measure 50mL of the above mixed solvent, and then add 0.05mol of FeCl 3 ·7H 2 Dissolve O in the above solution for use; Accurately weigh 0.05 mol of nanoscale Al powder according to the Fe / Al molar ratio of 1:1, disperse it in the above iron salt solution, and ultrasonicate for 0.5 hours to form a stable suspension After the solution was transferred to a 500mL three-necked flask, placed in an ice-salt bath, stirred for 10 minutes; NaBH with a concentration of 0.1mol / L was prepared with deionized water 4 Add 20mL of the solution dropwise to the three-necked flask under stirring conditions, and crystallize at 60°C for 3 hours after the dropwise addition. The whole reaction process does not need to be protected by an inert atmosphere, and the H 2 An oxygen-free environment can b...

Embodiment 3

[0031] Fully mix 1,4-butanediol and deionized water at a volume ratio of 5:1, and ultrasonicate the above solution for 0.5 hours to form a colorless and clear mixed solvent. Accurately measure 50 mL of the above mixed solvent, and then add 0.05 mol of FeSO 4 ·7H 2 Dissolve O in the above solution for use; Accurately weigh 0.05 mol of nanoscale Al powder according to the Fe / Al molar ratio of 1:1, disperse it in the above iron salt solution, and ultrasonicate for 0.5 hours to form a stable suspension After the solution was transferred to a 500mL three-necked flask, placed in an ice-salt bath, stirred for 10 minutes; NaBH with a concentration of 0.1mol / L was prepared with deionized water 4 Add 20mL of the solution dropwise to the three-necked flask under stirring conditions, and crystallize at 60°C for 3 hours after the dropwise addition. The whole reaction process does not need to be protected by an inert atmosphere, and the H 2 An oxygen-free environment can be provided. Aft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com