Preparation method for POSS/PDMAEMA organic/inorganic hybrid material according to thiol-ene click chemistry method

A technology of polydimethylaminoethyl methacrylate and dimethylaminoethyl methacrylate, applied in the field of new materials, to achieve high compatibility and thermal stability, excellent solubility, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

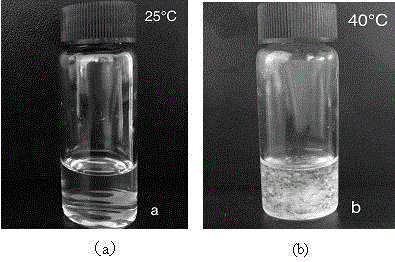

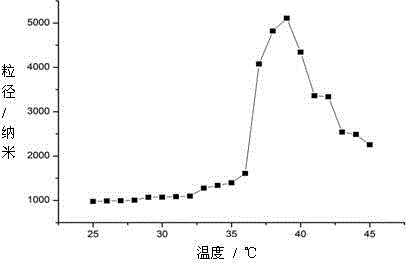

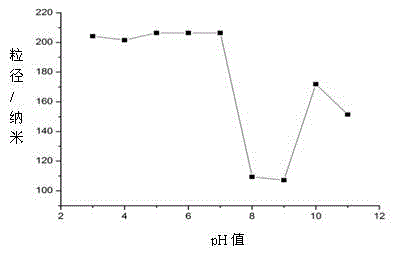

Image

Examples

Embodiment 1

[0033] Weigh 9.34g monomer dimethylaminoethyl methacrylate, 0.048g chain transfer agent 4-cyano-4-(thiobenzoyl)valeric acid, 0.0098g initiator 4,4'-azobisiso Add butyronitrile (AIBN) into a 50mL single-necked flask, slowly add 15mL of 1,4-dioxane to the single-necked flask, and dissolve completely; then place it in a water bath with a magnetic heating stirrer at 70°C for 12 hours to end the reaction Finally, the product was dialyzed in deionized water with a pH of 4.5 for 5 days, and the dialyzed solution was vacuum rotary evaporated at 45°C, and then vacuum-dried at 65°C for 24h to obtain light pink polydimethylaminoethyl methacrylate. Esters (PDMAEMA);

[0034] Weigh 0.5g of PDMAEMA obtained in step (1) and 1.0g of POSS containing vinyl groups respectively, place them in a 25mL single-necked flask, weigh 5mL of tetrahydrofuran to dissolve them, seal the single-necked flask with a rubber stopper, and then use a micro-sampler Add 29 μL dimethylphenylphosphine and 35 μL n-hexy...

Embodiment 2

[0036] Embodiment 2: Same as Example 1, but the consumption of chain transfer agent 4-cyano-4-(thiobenzoyl) valeric acid in step (1) is changed from 0.048g to 0.072g. 0.01~0.1g

Embodiment 3

[0037] Embodiment 3: Same as Example 1, but the consumption of chain transfer agent 4-cyano-4-(thiobenzoyl) valeric acid in step (1) is changed from 0.048g to 0.096g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com