UV hand feeling coating based on elastic urethane acrylate and preparation method of UV hand feeling coating

A polyurethane acrylate and elastic polyester technology, which is applied in the field of UV-curable hand-feel coatings, can solve problems such as poor fast curing ability and complicated curing process, and achieve convenient adjustment of coating hand feel, good adhesion, elasticity and flexibility good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A kind of preparation based on the UV feel paint of elastic polyurethane acrylate is as follows:

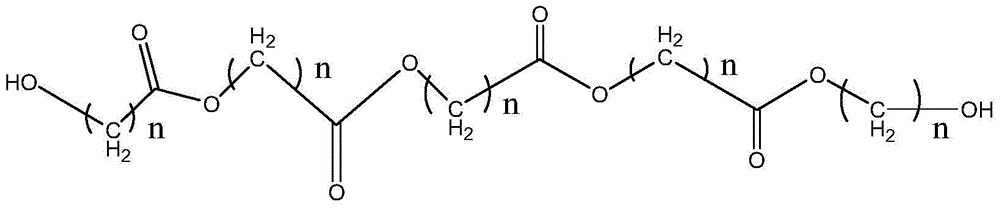

[0034] The structural formula of described elastic polyester diol is:

[0035]

[0036] Pretreatment of raw materials: vacuumize the elastic polyester diol at 110°C to remove moisture; and vacuumize pentaerythritol triacrylate and isophorone diisocyanate for several hours at 70°C Processing, the hydroxyethyl methacrylate containing 2,6-di-tert-butyl-4-methylphenol, hydroquinone and dibutyltin dilaurate is vacuum-dried in a vacuum oven;

[0037] Add 1.3g of pretreated isophorone diisocyanate and 2.5g of pentaerythritol triacrylate into a three-necked flask equipped with a thermometer, a reflux condenser, and a stirrer, and stir and mix evenly at 50°C. In the same way, within 1 hour, 5g of elastic polyester diol was added to the three-necked bottle in batches, and then the temperature was raised to 65°C. Measure the content of isocyanate after 1 hour of reaction, when t...

Embodiment 2

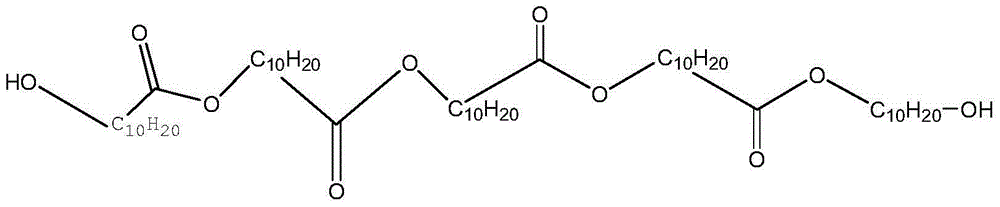

[0042] The structural formula of described elastic polyester diol is:

[0043]

[0044] Pretreatment of raw materials: vacuumize the elastic polyester diol at 110°C to remove moisture; reduce trimethylolpropane triacrylate and isophorone diisocyanate for several hours at 70°C Pressure vacuum treatment, in a vacuum drying oven, vacuumize the hydroxyethyl methacrylate containing bis(3,5-di-tert-butyl-4-hydroxyphenyl) sulfide, p-hydroxyanisole and stannous octoate dry;

[0045] Add 1.5g of pretreated isophorone diisocyanate and 2g of trimethylolpropane triacrylate into a three-neck flask equipped with a thermometer, a reflux condenser, and a stirrer, and stir and mix evenly at 50°C, then use In the way of adding multiple times, add 5.3g of elastic polyester diol to the three-necked bottle in batches within 1 hour, and then raise the temperature to 65°C. Measure the content of isocyanate after 1 hour of reaction, when the content of isocyanate reaches the theoretical value, it ...

Embodiment 3

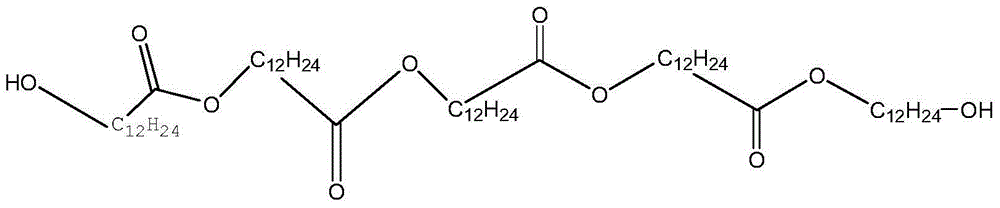

[0050] The structural formula of described elastic polyester diol is:

[0051]

[0052] Pretreatment of raw materials: vacuumize the elastic polyester diol at 120°C to remove moisture; trimethylolpropane triacrylate, pentaerythritol triacrylate, dipentaerythritol pentaacrylate at 80°C The mixture and isophorone diisocyanate are subjected to vacuum treatment under reduced pressure for several hours. -4-hydroxyphenyl) sulfide, hydroquinone and hydroxyethyl methacrylate of dibutyltin dilaurate are vacuum-dried;

[0053] Add 1.7g of pretreated isophorone diisocyanate and 1.2g of p-trimethylolpropane triacrylate, pentaerythritol triacrylate, dipentaerythritol pentaacrylate in a three-neck flask equipped with a thermometer, reflux condenser, and stirrer For the mixture of esters, stir and mix evenly at 55°C, add 5.7g of elastic polyester diol to the three-necked bottle in batches within 2 hours by adding multiple times, and then raise the temperature to 70°C . After reacting f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com