Paraffin-attapulgite composite phase-change material and preparation method thereof

A technology of composite phase change material and attapulgite, which is applied in the field of paraffin-attapulgite composite phase change material and its preparation, can solve the problems of low phase change enthalpy, complicated preparation methods, and low phase change enthalpy, and achieve high Thermal conductivity and phase change enthalpy, practical value for wide application, effect of improving adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

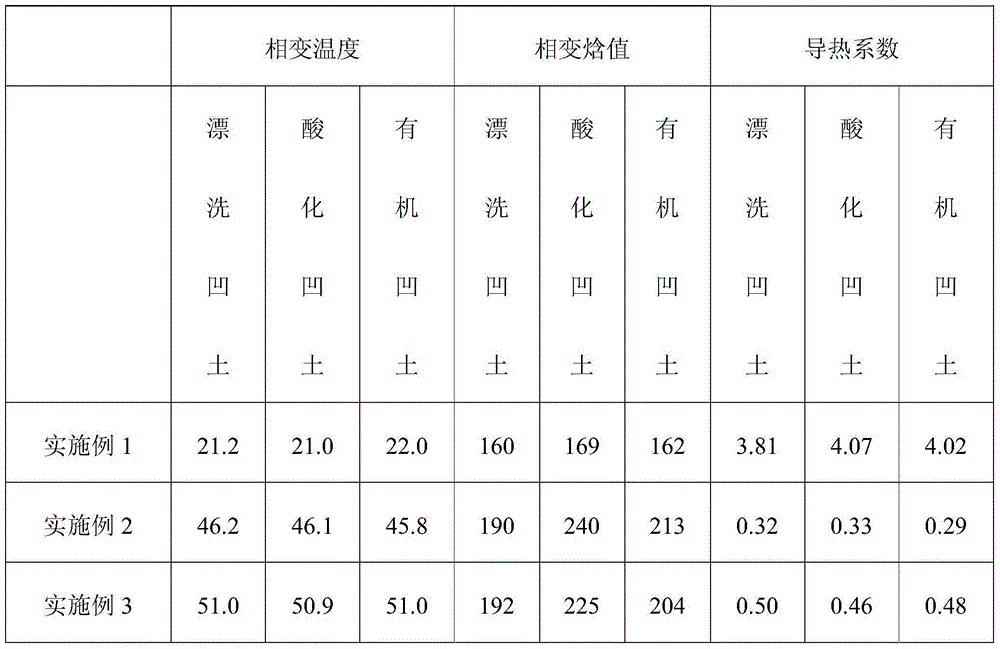

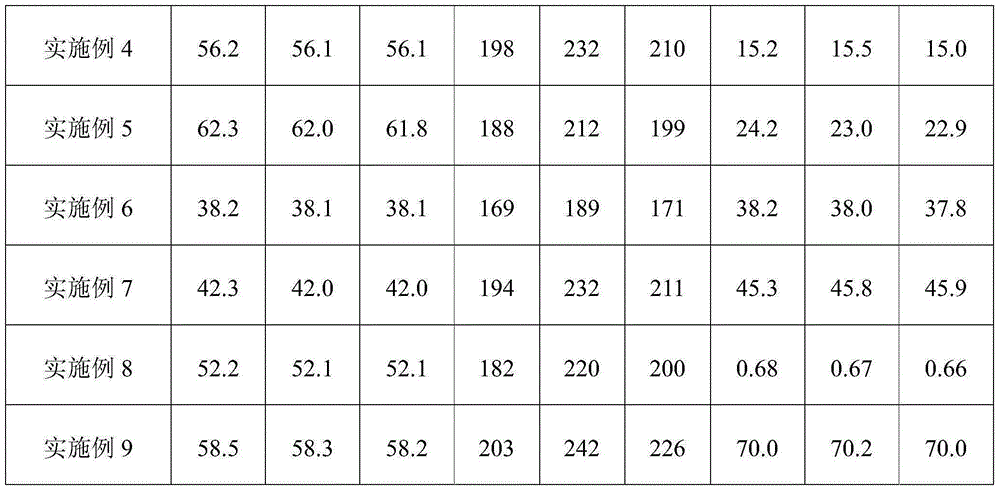

Embodiment 1

[0030] Mix attapulgite and water at a solid-to-liquid ratio of 1g: 5mL, stir thoroughly at 60°C for 1 hour, filter with suction, dry, crush and sieve to obtain 200-mesh rinsed attapulgite; rinse attapulgite with 5wt% The sulfuric acid solution was mixed according to the solid-to-liquid ratio of 1g: 3mL, stirred at 70°C for 6h, after the completion, the obtained slurry was filtered, washed until neutral, dried, crushed and sieved to obtain 200-mesh acidified attapulgite; Mix the rinsed attapulgite and water at a solid-to-liquid ratio of 1g: 5mL, stir and heat to 60°C, then add cetyltrimethylammonium bromide, whose mass is 5% of the mass of the rinsed attapulgite, stir After reacting for 2 hours, the resulting slurry was filtered, washed, dried, pulverized and sieved to obtain 200-mesh organic attapulgite.

[0031] Take 50g rinsed attapulgite, 50g acidified attapulgite, 50g organic attapulgite, and 0.5g Al 2 o 3 Mix evenly, add 100g of melted C17 alkane phase-change paraffin, ...

Embodiment 2

[0033] Referring to Example 1, the difference is: prepare rinsed attapulgite, attapulgite and water at a solid-to-liquid ratio of 1g: 8mL, stir at 80°C for 2h; prepare acidified soil, rinse attapulgite and 12wt% hydrochloric acid solution by The ratio is 1g: 6mL, stirring at 90°C for 5h; prepare organic attapulgite, acidified attapulgite and water according to the solid-liquid ratio of 1g: 12mL, the mass of octadecyltrimethylammonium bromide is the mass of acidified attapulgite 15wt%, stirred at 70°C for 5h; to prepare a composite phase change material, take 80g of rinsed attapulgite, 80g of acidified attapulgite, 80g of organic attapulgite, and mix evenly with 6g of foamed aluminum and 6g of expanded graphite, and add 120g of molten 48 No. phase-change paraffin, adsorbed at 60°C for 5h.

Embodiment 3

[0035] Referring to Example 1, the difference is: prepare rinsed attapulgite, attapulgite and water at a solid-to-liquid ratio of 1g:10mL, stir at 80°C for 2.5h; prepare acidified soil, rinse attapulgite and 25wt% nitric acid solution by solid The liquid ratio is 1g: 10mL, and stirred at 140°C for 3 hours; prepare organic attapulgite, acidified attapulgite and water according to the solid-liquid ratio of 1g: 15mL, the mass of cetyl dimethyl benzyl ammonium bromide is acidified attapulgite 20wt% of the mass of the soil, stirred at 80°C for 4 hours; to prepare a composite phase change material, take 100g of rinsed attapulgite, 100g of acidified attapulgite, 100g of organic attapulgite, and 10g of organic attapulgite, and mix them evenly with 10g of foamed copper, and add 150g of melted No. 50 Phase change paraffin, adsorption at 60°C for 5h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Phase transition temperature | aaaaa | aaaaa |

| Phase change enthalpy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com