Organic boron zirconium crosslinking agent

A technology of cross-linking agent and organic boron, which is applied in the field of oil field fracturing fluid, can solve the problems of difficulty in market production of organic boron-zirconium cross-linking agent, high raw material cost of organic boron-zirconium cross-linking agent, and reduction of economic benefits of oil field fracturing, etc. , to achieve the effect of improving the ability of seam making and carrying proppant, improving temperature resistance and shear resistance, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

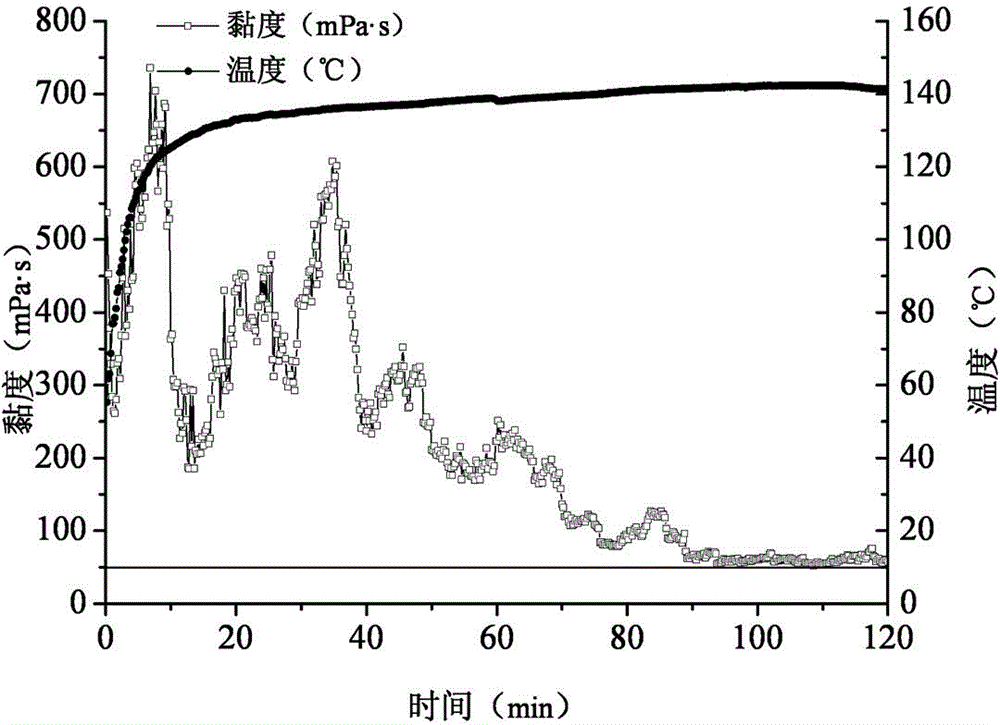

Embodiment 1

[0036] A kind of organic boron zirconium crosslinking agent, its formula is:

[0037] Calculated in parts by weight:

[0038] 1 part of zirconium oxychloride; 2 parts of water; 3 parts of isopropanol; 0.4 part of boric acid; 4 parts of methanol; 2 parts of glycerol; 1 part of sodium lactate; 1 part of triethanolamine;

[0039] This organic boron zirconium crosslinking agent is prepared by the following steps:

[0040] (1) Mix 10g of zirconium oxychloride with 20g of water and 30g of isopropanol to form a zirconium salt solution, add it to a flask, and feed ammonia gas into the solution at 55°C, and reflux for 0.5 hours;

[0041] (2) Add 20g of glycerol, 10g of sodium lactate, 10g of triethanolamine, and 5g of tetrahydroxypropylethylenediamine to the flask in sequence, and react for 3 hours;

[0042] (3) Add a boron solution composed of 4g of boric acid and 40g of methanol into the flask, and react for 3 hours to obtain a light yellow organic boron-zirconium crosslinking agen...

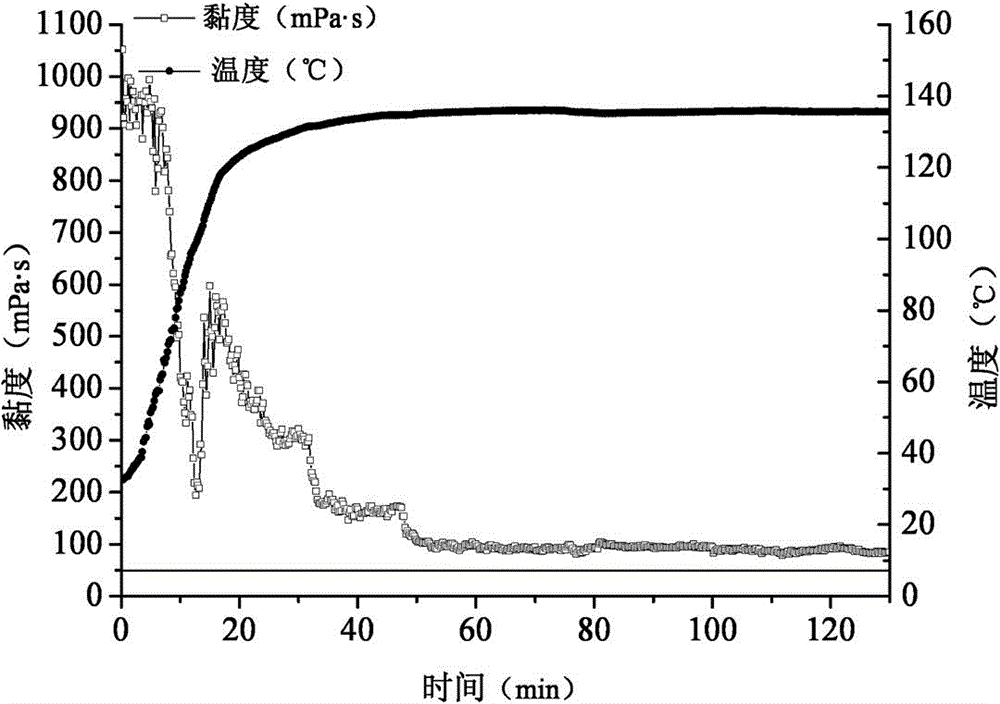

Embodiment 2

[0044] A kind of organic boron zirconium crosslinking agent, its formula is:

[0045] Calculated in parts by weight:

[0046] 1 part of zirconium oxychloride; 4 parts of water; 6 parts of isopropanol; 0.5 part of borax; 10 parts of methanol; 4 parts of ethylene glycol; 2 parts of sodium lactate; 2 parts of triethanolamine;

[0047] This organic boron zirconium crosslinking agent is prepared by the following steps:

[0048] (1) Mix 10g of zirconium oxychloride, 40g of water and 60g of isopropanol to form a zirconium salt solution, add it to a flask, and feed ammonia gas into the solution at 60°C, and reflux for 1 hour;

[0049] (2) Add 40g of ethylene glycol, 20g of sodium lactate, 20g of triethanolamine, and 5g of tetrahydroxypropylethylenediamine to the flask in sequence, and react for 2 hours;

[0050] (3) Add a boron solution composed of 5 g of borax and 100 g of methanol to the flask, and react for 2 hours to obtain a light yellow organic boron-zirconium crosslinking age...

Embodiment 3

[0052] A kind of organic boron zirconium crosslinking agent, its formula is:

[0053] Calculated in parts by weight:

[0054] 1 part of zirconium tetrachloride; 2 parts of water; 4 parts of isopropanol; 0.8 parts of boric acid; 8 parts of methanol; 4 parts of glycerol; 1 part of sodium gluconate; 1 part of triethanolamine; share.

[0055] This organic boron zirconium crosslinking agent is prepared by the following steps:

[0056] (1) Mix 10g of zirconium tetrachloride, 20g of water and 40g of isopropanol to form a zirconium salt solution, add it to a flask, and feed ammonia gas into the solution at 58°C, and reflux for 1 hour;

[0057] (2) Add 40g of glycerol, 10g of sodium gluconate, 10g of triethanolamine, and 10g of tetrahydroxypropylethylenediamine to the flask in sequence, and react for 3 hours;

[0058] (3) Add a boron solution composed of 8g boric acid and 80g methanol to the flask, and react for 2 hours to obtain a light yellow organic boron-zirconium crosslinking a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com