Perindopril tablets and direct tabletting process of perindopril tablet powder

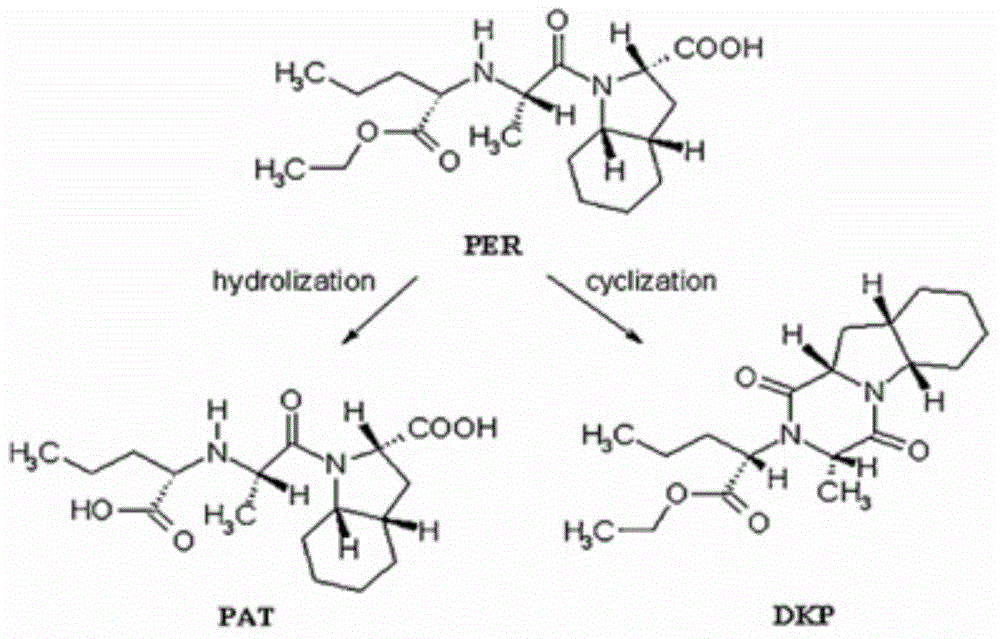

A technology of indopril tablets and powders, which is applied in the field of direct compression of perindopril tablets and powders, can solve the problem that the content of degraded impurities B and F increases obviously, and it is difficult to meet the product quality of enterprises and adapt to market demands, etc. problems, to achieve the effect of being conducive to stability and production controllability, avoiding granulation and drying processes, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

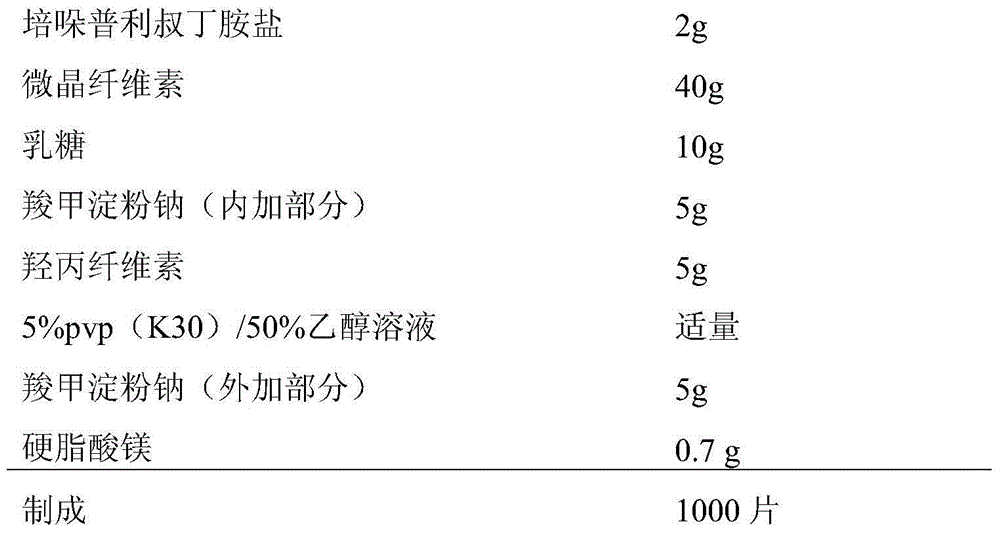

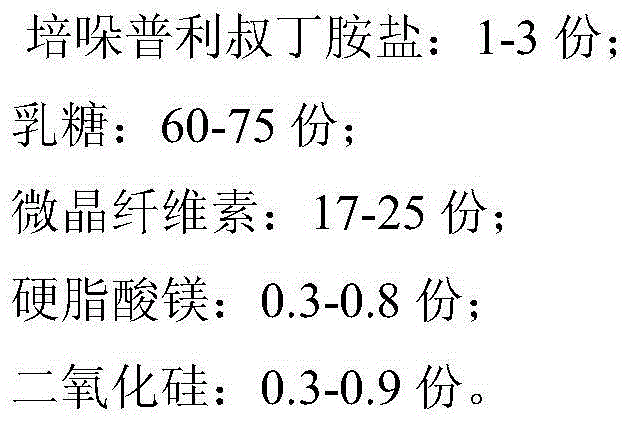

[0033] A kind of perindopril tablet, described perindopril tablet is made up of following components according to parts by weight:

[0034]

[0035] The direct compression process of perindopril sheet powder comprises the steps:

[0036] (1) Get perindopril tert-butylamine salt, mix with microcrystalline cellulose, sieve, and mix; the mesh of the sieve is 80 mesh;

[0037] (2) Mix with part of lactose again;

[0038] (3) Mix the above mixed powder with remaining lactose and silicon dioxide;

[0039] (4) Add magnesium stearate to mix at last, sampling detection, tabletting;

[0040] (5) It is packaged in aluminum-plastic blister, with a built-in desiccant and a composite film bag outside. Aluminum-plastic blister packaging, specifically: PVC+aluminum foil, desiccant is silica gel.

Embodiment 2

[0042] A kind of perindopril tablet, described perindopril tablet is made up of following components according to parts by weight:

[0043]

[0044] The direct compression process of perindopril sheet powder comprises the steps:

[0045] (1) Get perindopril tert-butylamine salt, mix with microcrystalline cellulose, sieve, and mix; the mesh of the sieve is 100 mesh;

[0046] (2) Mix with part of lactose again;

[0047] (3) Mix the above mixed powder with remaining lactose and silicon dioxide;

[0048] (4) Add magnesium stearate to mix at last, sampling detection, tabletting;

[0049] (5) Aluminum-plastic blister packaging with built-in desiccant and composite film bag outside; aluminum-plastic blister packaging, specifically: PVC+aluminum foil, desiccant is molecular sieve.

Embodiment 3

[0051] A kind of perindopril tablet, described perindopril tablet is made up of following components according to parts by weight:

[0052]

[0053] The direct compression process of perindopril sheet powder comprises the steps:

[0054] (1) Get perindopril tert-butylamine salt, mix with microcrystalline cellulose, sieve, and mix; the mesh of the sieve is 80 mesh;

[0055] (2) Mix with part of lactose again;

[0056] (3) Mix the above mixed powder with remaining lactose and silicon dioxide;

[0057] (4) Add magnesium stearate to mix at last, sampling detection, tabletting;

[0058] (5) It is packaged in aluminum-plastic blister, with a built-in desiccant and a composite film bag outside. Aluminum-plastic blister packaging, specifically: PVC+aluminum foil, desiccant is silica gel.

[0059] The perindopril tert-butylamine obtained by the above examples is needle-shaped, and through microscopic observation, the length is about 100-200 μm. When it encounters water, it can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com