Lightweight aggregate concrete suitable for high remote pumping

A lightweight aggregate concrete and pumping technology, which is applied in the field of concrete, can solve the problems of large component delamination, reduced pumpability, and easy floating of aggregates, and achieve good workability and homogeneity, easy pumping, The effect of good pumpability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

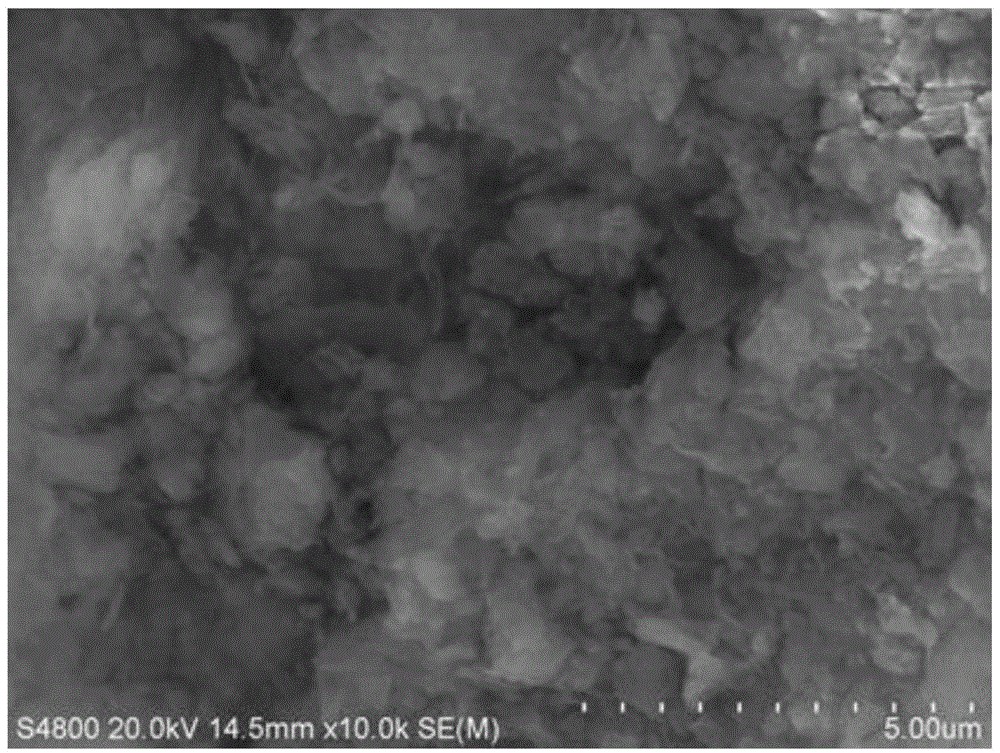

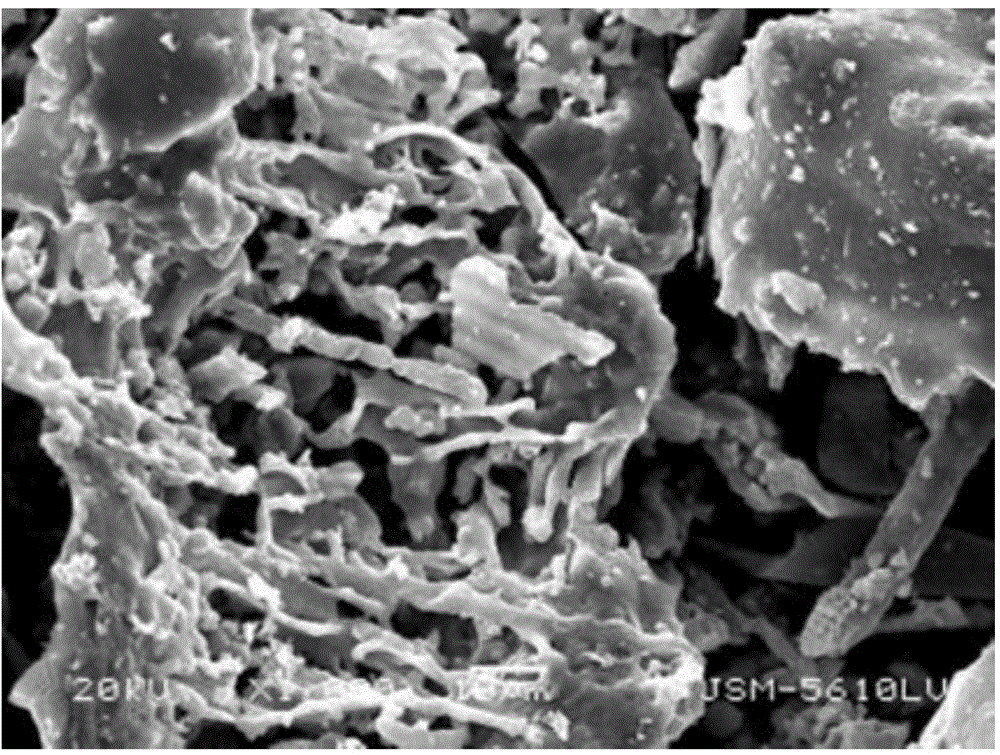

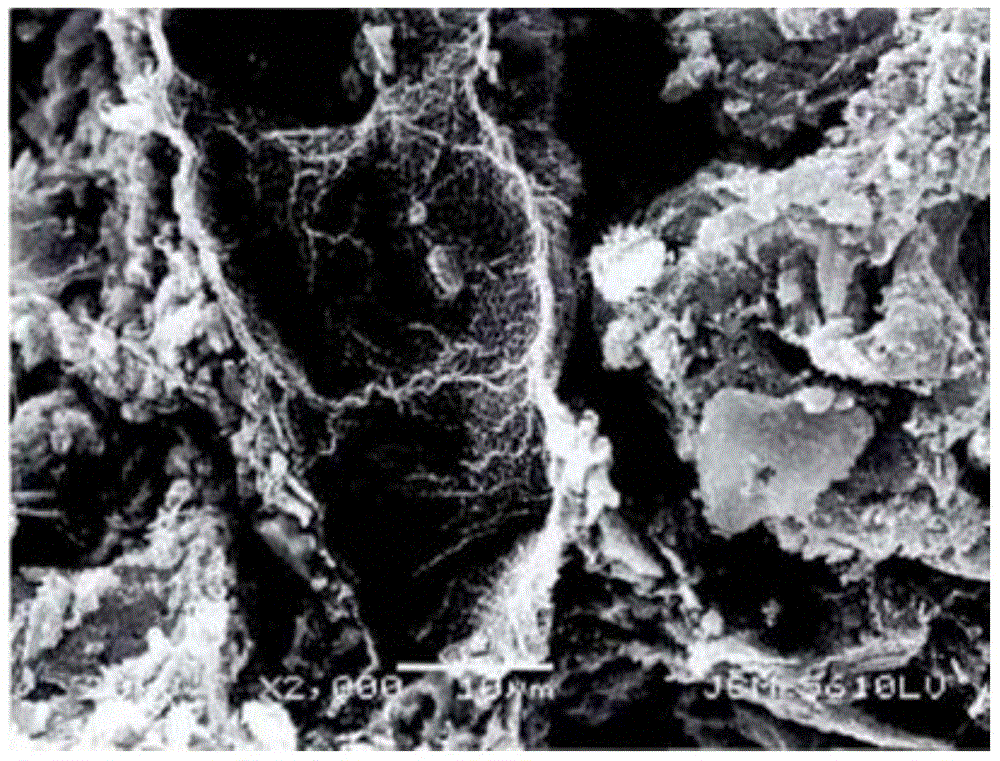

Method used

Image

Examples

Embodiment 1

[0034] A lightweight aggregate concrete suitable for high-distance pumping. The mass percentages of its components are: cement paste 36.5%, light coarse aggregate 30.5%, and fine aggregate 33.0%.

[0035] The cement paste is 51.4% by mass percentage of P.O42.5 cement, 14.0% of primary fly ash, 4.2% of silica fume, 2.8% of inorganic viscosity modifier, 0.1% of cellulose ether , 26.5% water and 1.0% polycarboxylate high-efficiency water reducer are evenly mixed. The measured viscosity of the cement slurry is 20mPa·s and the density is 1877kg / m 3 .

[0036] The light coarse aggregate is 800-grade shale ceramsite produced by Yichang Guangda Ceramic Products Co., Ltd., with a particle size range of 4.75 to 20mm; 1h water absorption rate of 4.5%; saturated water absorption rate of 8.7%; apparent density of 1587kg / m 3 , and the difference between the density of cement paste is 290kg / m 3 .

[0037] The fine aggregate is natural river sand with a particle size not greater than 4.75m...

Embodiment 2

[0049] A lightweight aggregate concrete suitable for high-distance pumping. The mass percentages of its components are: cement paste 33.3%, light coarse aggregate 28.4%, and fine aggregate 38.3%.

[0050] The cement paste is 45.5% P.O42.5 cement by mass percentage, 13.1% primary fly ash, 3.0% silica fume, 3.0% inorganic viscosity modifier, 6.6% light powder 27.8% water and 1.0% polycarboxylate high-efficiency water reducer are uniformly mixed. The measured viscosity of the cement slurry is 17mPa·s and the density is 1720kg / m 3 .

[0051] The light coarse aggregate is 700-grade shale ceramsite produced by Yichang Everbright Ceramic Products Co., Ltd., with a particle size range of 4.75 to 20mm; 1h water absorption rate of 4.8%; saturated water absorption rate of 9.1%; apparent density of 1390kg / m 3 , and the difference between the density of the cement paste is 330kg / m 3 .

[0052] The fine aggregate is natural river sand with a particle size not greater than 4.75mm, the riv...

Embodiment 3

[0064] A lightweight aggregate concrete suitable for high-distance pumping. The mass percentages of its components are: cement paste 41.0%, light coarse aggregate 28.5%, and fine aggregate 30.5%.

[0065] The cement paste is 37.3% by mass percentage of P.O42.5 cement, 16.3% of primary fly ash, 3.4% of silica fume, 8.3% of light powder, and 3.1% of inorganic viscosity modified 0.2% cellulose ether, 30.5% water and 0.9% polycarboxylate high-efficiency superplasticizer are uniformly mixed. The measured viscosity of the cement slurry is 21mPa·s and the density is 1621kg / m 3 .

[0066] The light coarse aggregate is 600-grade shale ceramsite produced by Yichang Everbright Ceramic Products Co., Ltd., with a particle size range of 4.75 to 20mm; 1h water absorption rate of 5.5%; saturated water absorption rate of 10.0%; apparent density of 1170kg / m 3 , and the difference between the density of the cement paste is 451kg / m 3 .

[0067] The fine aggregate is grade 800 shale pottery san...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com