One-component water-based solid color paint for car and preparation process of the one-component water-based solid color paint

A one-component, water-based technology, applied in coatings, polyurea/polyurethane coatings, etc., can solve the physical and mechanical properties of plain paints, water resistance, chemical resistance and weather resistance defects, poor compatibility, and factors affecting Solve the problem of equal color of the paint, achieve the effect of excellent physical and mechanical properties, excellent storage stability, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment A

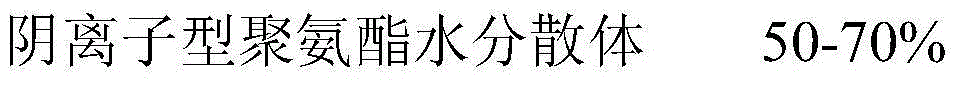

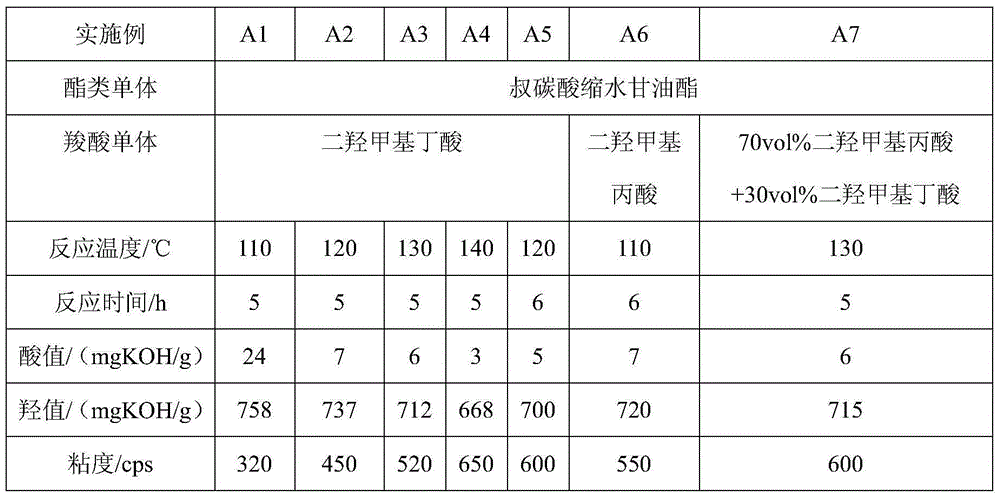

[0032] Example A Synthesis of prepolymer monomers

[0033] Add equimolar amounts of glycidyl tert-carbonate and (dimethylol butyric acid and / or dimethylol propionic acid) in a three-necked flask equipped with a stirrer, an oil bath, and a thermometer. At different temperatures, the reactions are different. Time, obtain the prepolymer monomer-dimethylol tertiary carbonate. Among them, the epoxy equivalent of glycidyl tert-carbonate is 240g / mol, and the viscosity at 25°C is 80cps; the original acid value of dimethylol butyric acid is 376mgKOH / g, and the hydroxyl value is 758mgKOH / g; The original acid value of propionic acid is 416 mgKOH / g, and the hydroxyl value is 825 mgKOH / g. The list of each embodiment in the embodiment group A is shown in Table 1.

[0034] Table 1 List of Example A

[0035]

[0036] Note: The viscosity of the intermediate is measured at room temperature 25°C, using Brookfield DV-II rotational viscometer, No. 3 spindle, 5 revolutions / min.

[0037] By c...

Embodiment B

[0038] Example B: Synthesis of Anionic Polyurethane Aqueous Dispersion (PUD)

[0039] The synthesis of the anionic polyurethane aqueous dispersion of the present invention will be described below in conjunction with preferred examples. The dimethylol tertiary carbonate in the formula can be synthesized by oneself or purchased, preferably satisfying the acid value≤7mgKOH / g. The dimethylol tertiary carbonate synthesized in preferred embodiment A2 in the following examples. To illustrate here: this is only an illustration, and the dimethylol tertiary carbonate synthesized by other routes in the prior art can also realize the present invention.

Embodiment B1

[0041] Add polycarbonate diol and polyester diol into the reaction kettle, heat up to 110-115°C, vacuumize for 0.5h to remove moisture; then cool down to 50-55°C, add the prepolymer monomer synthesized in Example A2, Chain-extending monomers, cross-linking monomers, diisocyanate monomers, catalysts and co-solvents, wherein the molar ratio of primary hydroxyl groups carried by each component monomer to isocyanate is 1.3:1; the temperature is raised to 65-70 °C for 1 hour, then raised to 85°C-90°C for reaction, and stopped the reaction when the isocyanate group value in the system was 0 to obtain a polyurethane solution.

[0042] Deionized water is added into the polyurethane solution for emulsification to obtain the anionic polyurethane aqueous dispersion.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com