Super-hydrophilic and underwater super-oleophobic coating, as well as preparation method and application thereof

An underwater super-oleophobic and super-hydrophilic technology, applied in antifouling/underwater coatings, coatings, paints containing biocide, etc., can solve the problems of cumbersome preparation process, cumbersome technical process, and poor stability, and achieve The method has the advantages of simple process, readily available raw materials and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] (1) Dissolve 5.0g of alkoxysilane-functionalized betaine-type zwitterionic compound in 95.0g of ethanol at room temperature, adjust the pH of the solution to 2 with 0.1M hydrochloric acid solution, hydrolyze and age for 4 hours, and obtain A solution ;

[0040] (2) Add 5.0g of nano-silica with a size of 50nm to 95.0g of methanol solvent to obtain B solution;

[0041] (3) At room temperature, mix 10.0g of A solution, 2.0g of B solution, 0.2g of isopropanol, 0.1g of water and 2g of ethyl orthosilicate and stir evenly to obtain a mixed solution;

[0042] (4) Clean the glass surface and dry it at room temperature;

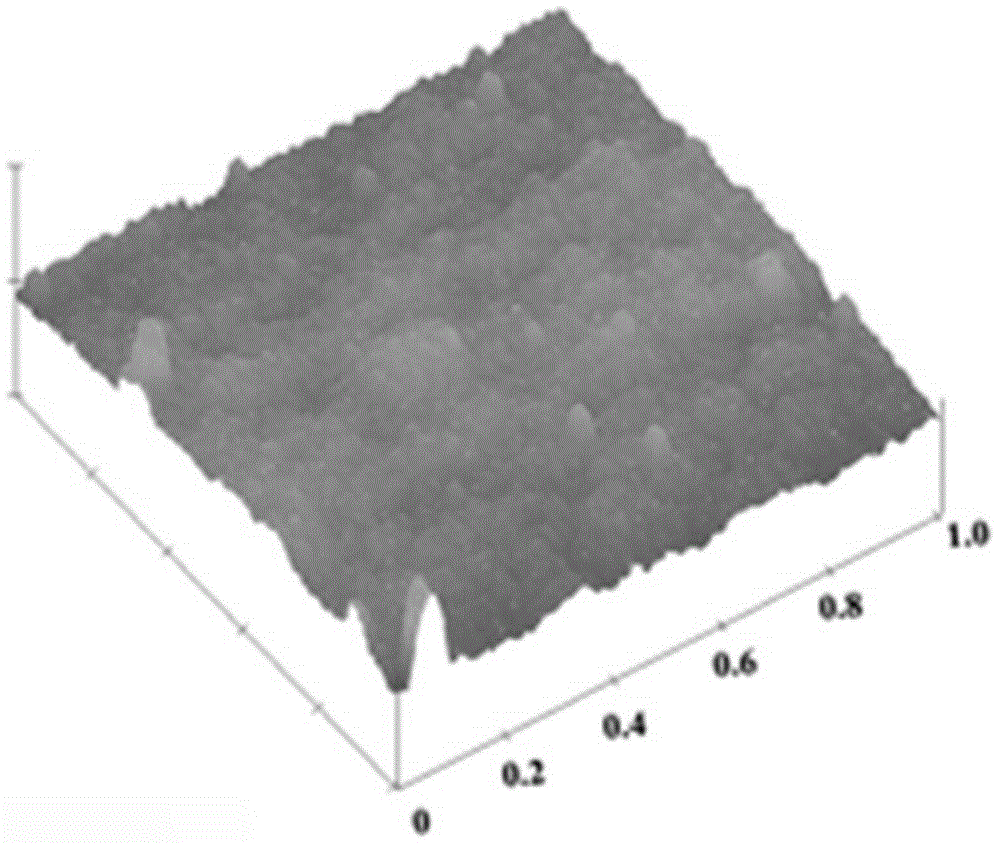

[0043] (5) By spraying, apply the mixed solution of step (3) on the clean glass surface and treat it at 80°C for 30 minutes to obtain a super-hydrophilic and underwater super-oleophobic coating. The three-dimensional surface of the coating Microstructure as attached figure 1 shown.

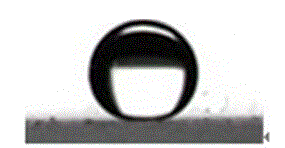

[0044] The thickness of the prepared coating is 10 μm, and the contact ang...

Embodiment 2

[0049] (1) Dissolve 5.0g of alkoxysilane-functionalized betaine-type zwitterionic compound in 450.0g of methanol at room temperature, adjust the pH of the solution to 5 with 0.1M hydrochloric acid solution, hydrolyze and age for 1 hour, and obtain A solution ;

[0050] (2) Add 5.0g of nano-silica with a size of 100nm to 450.0g of ethanol solvent to obtain B solution;

[0051] (3) At room temperature, mix 50.0 g of A solution, 1.0 g of B solution, 0.2 n-butanol, and 0.1 g of water and stir evenly to obtain a mixed solution;

[0052] (4) Clean the glass surface and dry it at room temperature;

[0053] (5) Using the method of shower coating, apply the mixed solution of step (3) to the clean glass surface and treat it at 160°C for 100 minutes to obtain a super-hydrophilic and underwater super-oleophobic coating. The three-dimensional microstructure is attached Image 6 shown.

[0054] The thickness of the prepared coating is 100 μm, and the contact angle of the surface with wat...

Embodiment 3

[0058] (1) Dissolve 20.0g of alkoxysilane-functionalized betaine-type zwitterionic compound in 95.0g of methanol at room temperature, adjust the pH of the solution to 7 with 0.1M hydrochloric acid solution, hydrolyze and age for 5 hours, and obtain A solution ;

[0059] (2) Add 5.0 g of nano-silica with a size of 50 nm into 145.0 g of isopropanol solvent to obtain B solution;

[0060] (3) At room temperature, mix 10.0g of A solution, 20.0g of B solution, 10.0g of water and 2g of methyl orthosilicate and stir evenly to obtain a mixed solution;

[0061] (4) Clean the glass surface and dry it at room temperature;

[0062] (5) Apply the mixed solution in step (3) to a clean glass surface by spraying, and place it at 120°C for 30 minutes to obtain a superhydrophilic and underwater superoleophobic coating.

[0063] The thickness of the prepared coating is 50 μm, and the contact angle of the surface with water in air is 3°; the contact angle with hexadecane under water is 150°.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com