Adhesive and preparation method thereof

A technology of adhesives and curing agents, applied in the direction of adhesives, adhesive types, polyurea/polyurethane adhesives, etc., can solve the problem of low dielectric constant, achieve high relative dielectric constant, easy assembly, adhesion strong relay effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

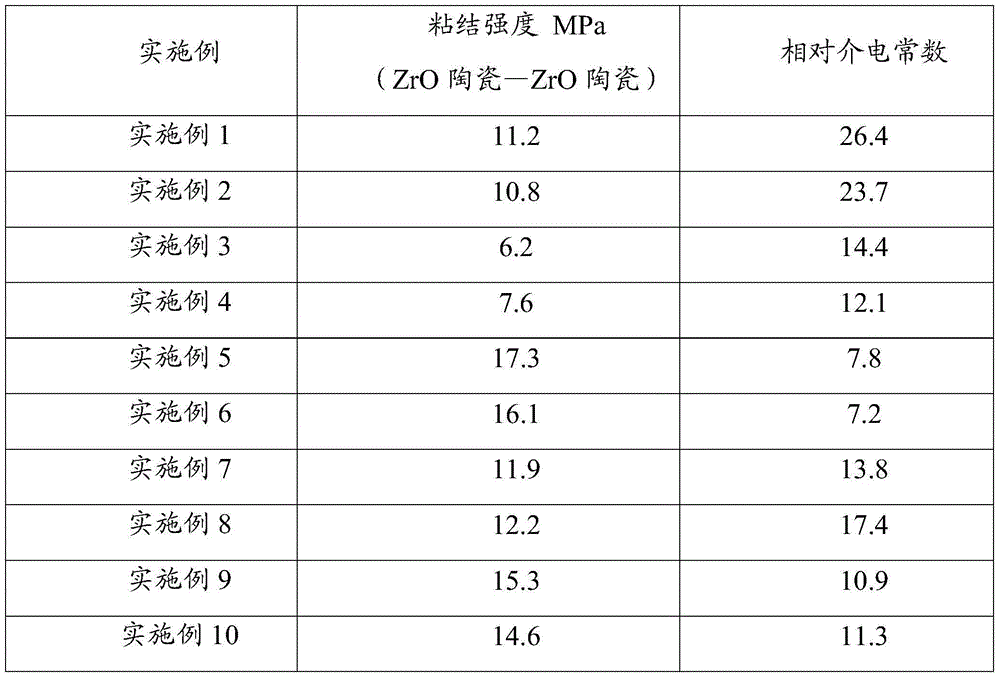

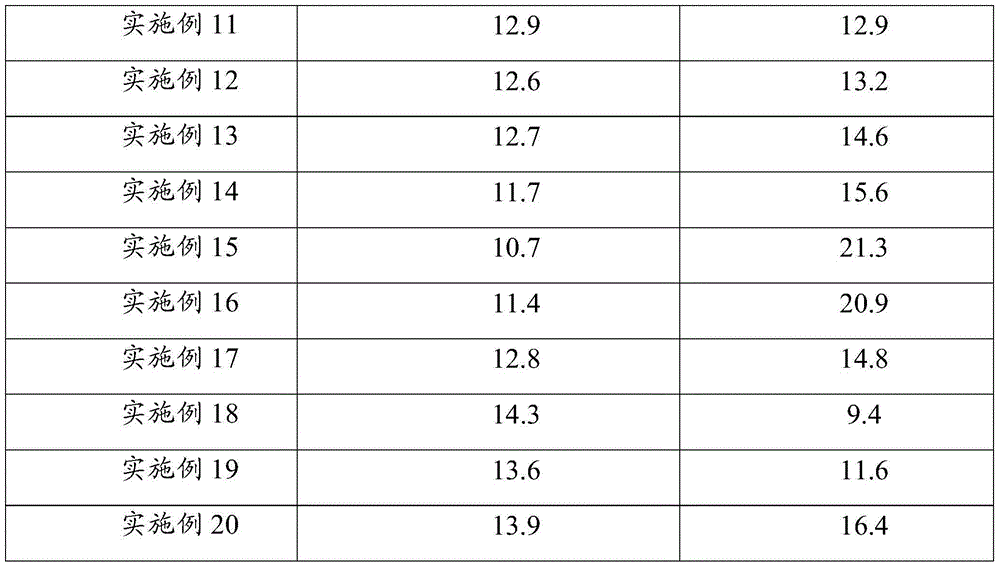

Examples

Embodiment 1

[0045] An embodiment of the adhesive of the present invention, the adhesive includes the following components in parts by weight: 100 parts of matrix resin, 10 parts of curing agent, 6 parts of accelerator, 350 parts of filler with high dielectric constant, 5 parts of dispersant, 5 parts of coupling agent, and 15 parts of toner; the adhesive also includes anti-settling agent and diluent, and its addition amount is 9.9 parts.

[0046] The base resin is epoxy resin, the diluent is diluent 692, the curing agent is dicyandiamide, the accelerator is an organic urea accelerator, the dispersant is lecithin, and the coupling The agent is silane coupling agent KH550, the high dielectric constant filler is sodium potassium niobate, the anti-sedimentation agent is polyamide wax, and the toner is carbon black.

[0047] A kind of embodiment of the preparation method of above-mentioned adhesive, described preparation method comprises the following steps:

[0048] Under vacuum conditions, a...

Embodiment 2

[0050] An embodiment of the adhesive of the present invention, the adhesive includes the following components by weight: 100 parts of matrix resin, 8 parts of curing agent, 6 parts of accelerator, 350 parts of filler with high dielectric constant, 5 parts of dispersant, 5 parts of coupling agent, and 15 parts of toner; the adhesive also includes anti-sedimentation agent and diluent, the addition amount of which is 8 parts.

[0051] The base resin is epoxy resin, the diluent is diluent 692, the curing agent is dicyandiamide, the accelerator is an organic urea accelerator, the dispersant is lecithin, and the coupling The agent is silane coupling agent KH550, the high dielectric constant filler is sodium niobate, the anti-sedimentation agent is polyamide wax, and the toner is carbon black.

[0052] A kind of embodiment of the preparation method of above-mentioned adhesive, described preparation method comprises the following steps:

[0053] Under the condition of vacuum and no m...

Embodiment 3

[0055] An embodiment of the adhesive of the present invention, the adhesive includes the following components in parts by weight: 100 parts of matrix resin, 4.3 parts of curing agent, 140 parts of filler with high dielectric constant, 1.5 parts of dispersant, 1.2 parts of coupling agent, 10 parts of toner; said adhesive also includes anti-settling agent and diluent, the addition amount of which is 11 parts.

[0056] The matrix resin is a blocked polyurethane prepolymer (containing 9%-NCO), the diluent is diluent 692, the curing agent is 1,4-butanediol, and the dispersant is dispersant 9400, The coupling agent is silane coupling agent KH-550, the high dielectric constant filler is barium titanate, the anti-sedimentation agent is polyamide wax, and the toner is carbon black.

[0057] A kind of embodiment of the preparation method of above-mentioned adhesive, described preparation method comprises the following steps:

[0058] Under vacuum conditions, add 140 parts by weight of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com