Method of producing exoinulinase with utilization of solid state fermentation of streptomyces grisepoplanus S501

A technology of exo-inulinase and Streptomyces griseignis, which is applied in the field of microorganisms, can solve problems such as environmental pollution, waste, and unsuitability for industrial production, and achieve the effect of overcoming high cost and improving the activity of exo-inulinase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] Preparation of fructose standard curve:

[0039] Take 1mg / mL fructose standard solution 0, 0.2, 0.4, 0.6, 0.8, 1.0, 1.2, 1.4, 1.6mL respectively in test tubes, add distilled water to make up to 2.0mL, add 1.5mL of DNS solution respectively, mix well, put in boiling water bath React for 5 minutes, cool to room temperature, set the volume to 25.0mL, mix well, measure the absorbance value at 540nm, draw the fructose standard curve with the fructose content as the abscissa and the absorbance value (Abs) as the ordinate.

[0040] DNS inulinase activity assay:

[0041] The DNS method was used to determine the average value of three parallel experiments, and the fructose standard curve method was used to calculate the reducing sugar content. At the same time, the solid-state fermentation medium without inoculation was used as a control. The unit of inulinase activity is defined as: at 50°C, the amount of enzyme required to convert inulin into 1 μmol of reducing sugar per min...

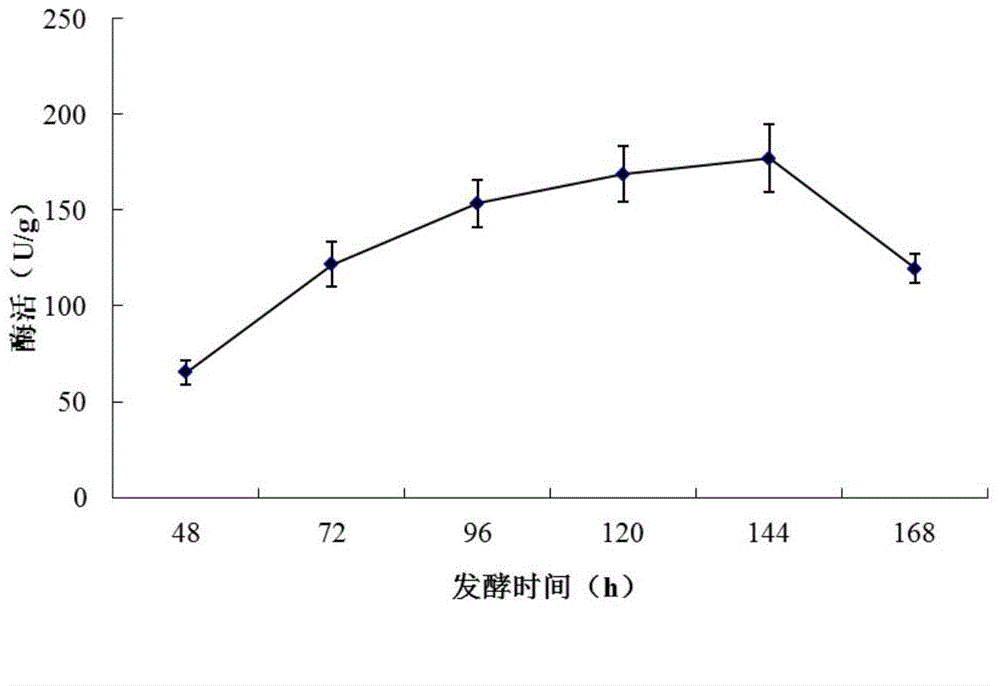

Embodiment 1

[0049] 1. Strain culture

[0050] Make the lyophilized powder of strain S501 into a bacterial suspension with sterile water, dip an appropriate amount on the selection medium with a sterile swab, and cultivate it at 28°C for 3-5 days, and gently scrape off the spores on the plate with a sterile spatula , placed in sterile water and diluted to a spore suspension concentration of 10 6 cfu / mL.

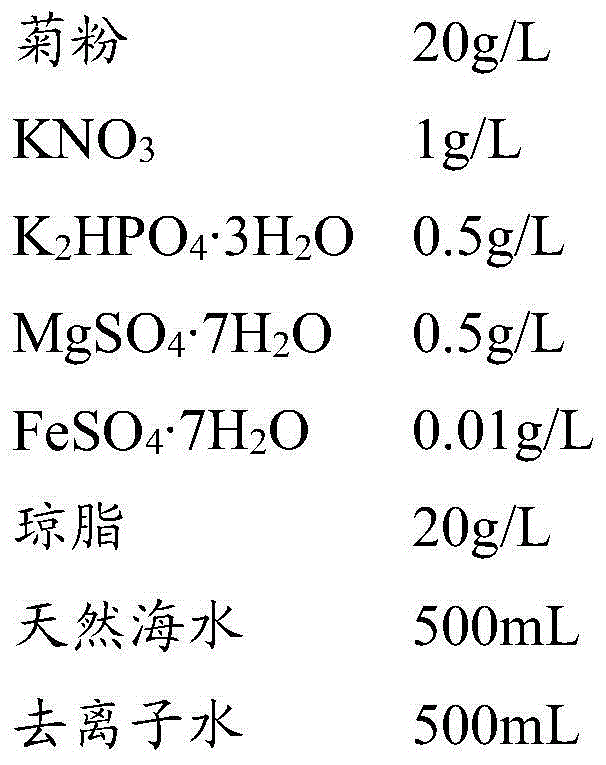

[0051] Described selection medium is made up of the component that comprises following content:

[0052]

[0053]

[0054] The selection medium has a pH of 7.2 and is autoclaved at 112° C. for 20 minutes.

[0055] 2. Exo-inulinase Preparation

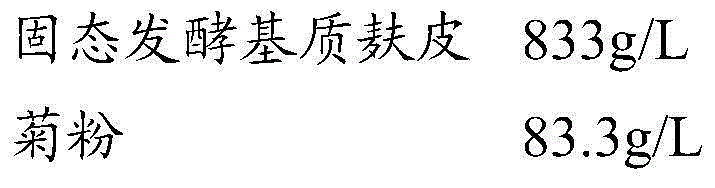

[0056] The above-mentioned bacterial suspension was inserted into a solid-state fermentation medium with an inoculation amount of 8% (v / w), and cultured statically at 28° C. for 6 days; the components of the solid-state fermentation medium were:

[0057]

[0058] The above-mentioned solid-state fermentation culture was sterilized under...

Embodiment 2

[0060] 1. Strain culture

[0061] Make the lyophilized powder of strain S501 into a bacterial suspension with sterile water, dip an appropriate amount on the selection medium with a sterile swab, and cultivate it at 28°C for 3-5 days, and gently scrape off the spores on the plate with a sterile spatula , placed in sterile water and diluted to a spore suspension concentration of 10 6 cfu / mL.

[0062] Described selection medium is made up of the component that comprises following content:

[0063]

[0064]

[0065] The selection medium has a pH of 7.2 and is autoclaved at 112° C. for 20 minutes.

[0066] 2. Exo-inulinase Preparation

[0067] The above-mentioned bacterial suspension was inserted into a solid-state fermentation medium with an inoculation amount of 8% (v / w), and cultured statically at 28° C. for 6 days; the components of the solid-state fermentation medium were:

[0068]

[0069] The pH of the solid-state fermentation medium is 8.0, and it is autoclave...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com