Methyl 3-(2-(2-hydroxyethoxy)ethoxy)propanoate modification agent detection method

A technology of methyl diethylene glycol propionate and a detection method, applied in the detection field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

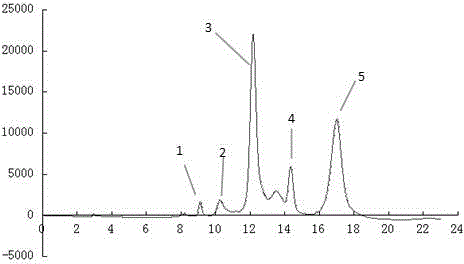

Image

Examples

Embodiment 1

[0022] Preparation of methyl diethylene glycol propionate: Add diethylene glycol and methyl acrylate to ether, first ultrasonically vibrate for half an hour, then add catalyst nano-gold, ultrasonic power is 65-85kw, then continue to vibrate for 1.5 hours, under pressure 0.1Mpa, the reaction temperature is 10°C to start the reaction, and the reaction time is 5 hours. Wherein, the consumption of nano-gold is 0.5% of the total mass of diethylene glycol and methyl acrylate, the consumption of ether is 10% of the total mass of diethylene glycol and methyl acrylate, and the mass ratio of diethylene glycol to methyl acrylate 1:1.

[0023] Diethylene glycol propionate methyl esterification modifier detection:

[0024] a) Preparation of standard stock solution: Weigh 100mg of methyl diethylene glycol propionate, dissolve in water and set the volume to 1000mL to obtain standard stock solution, and store at 4°C;

[0025] b) Preparation of standard solution: pipette 1, 2, 3, 4 and 5mL o...

Embodiment 2

[0029] Preparation of methyl diethylene glycol propionate: Add diethylene glycol and methyl acrylate to ethanol, first ultrasonically vibrate for half an hour, then add catalyst nano-silver, ultrasonic power is 65-85kw, then continue to vibrate for half an hour, under pressure 0.5Mpa, the reaction temperature is 180°C to start the reaction, and the reaction time is 8 hours. Wherein, the consumption of nano-silver is 0.8% of the total mass of diethylene glycol and methyl acrylate, the consumption of ethanol is 15% of the total mass of diethylene glycol and methyl acrylate, the mass ratio of diethylene glycol and methyl acrylate It is 1:1.2.

[0030] Diethylene glycol propionate methyl esterification modifier detection:

[0031] a) Preparation of standard stock solution: Weigh 100mg of methyl diethylene glycol propionate, dissolve in water and set the volume to 1000mL to obtain standard stock solution, and store at 4°C;

[0032] b) Preparation of standard solution: pipette 1, ...

Embodiment 3

[0036] Preparation of methyl diethylene glycol propionate: Add diethylene glycol and methyl acrylate to acetonitrile, first vibrate ultrasonically for half an hour, then add catalyst cerium oxide and nano-magnesium oxide, the ultrasonic power is 65-85kw, and then continue to vibrate for 2.5 Hours, the reaction was started at a pressure of 0.8Mpa and a reaction temperature of 220° C., and the reaction time was 10 hours. Wherein, the consumption of cerium oxide and nano magnesium oxide is 1.1% of the total mass of diethylene glycol and methyl acrylate, cerium oxide and nano magnesium oxide each account for half, and the consumption of acetonitrile is 1.1% of the total mass of diethylene glycol and methyl acrylate. 20%, the mass ratio of diethylene glycol to methyl acrylate is 1:1.85.

[0037] Diethylene glycol propionate methyl esterification modifier detection:

[0038] a) Preparation of standard stock solution: Weigh 100mg of methyl diethylene glycol propionate, dissolve in w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com