Ferroferric oxide/silver composite material and manufacturing method and application of ferroferric oxide/silver composite material

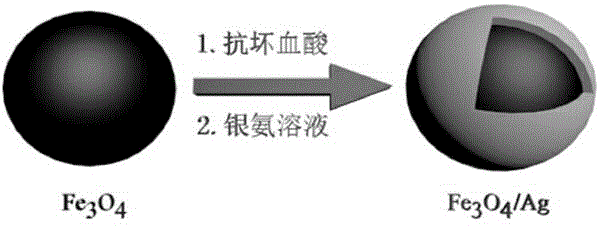

A technology of ferric tetroxide and composite materials, which is applied in the field of preparation of core-shell structure composite materials, can solve the problems of complicated operation, reduced detection signal intensity, waste of energy, etc., and achieves simple preparation method, good dispersibility, and good SERS enhancement. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Fe 3 o 4 Particle preparation method: in 1.35g FeCl 3 ·6H 2 Add 40 mL of ethylene glycol to O and stir magnetically until FeCl 3 ·6H 2 O was completely dissolved, then added 3.6 g NaAc and 1.0 g polyethylene glycol, and stirred for 1 h to obtain a homogeneous mixture. Then the mixture was transferred to a 50 mL stainless steel reaction kettle with a polytetrafluoroethylene liner, and the reaction kettle was heated to 200 °C in a blast drying oven, kept for 8 h, and then naturally cooled to room temperature. The obtained product was collected by a magnet, washed three times with distilled water, then washed three times with absolute ethanol, collected by a magnet, and then dried in a vacuum oven at 60 °C for 6 h to obtain a black powder.

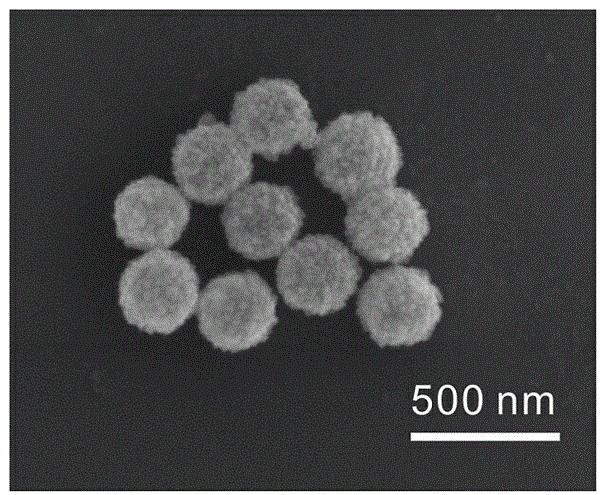

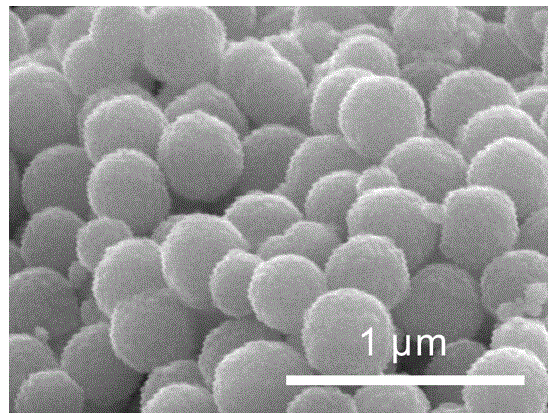

[0028] Take a small amount of the above-mentioned black powder, add distilled water and ultrasonically disperse it, drop the dispersion onto a silicon wafer, and test it on a scanning electron microscope after natural drying to ob...

Embodiment 2

[0030] Fe 3 o 4 The preparation method of / Ag composite material: get the Fe in embodiment 1 3 o 4 Add 8 mL of distilled water to 40 mg of particles, and ultrasonically disperse for 5 min to obtain Fe 3 o 4 Dispersion A. Take 100 μL of dispersion A and add it to 195 mL of distilled water, stir evenly to obtain dispersion B, add 4 mL of 0.1 mol / L ascorbic acid aqueous solution under constant stirring, and then add 0.1 mol / L of [Ag(NH 3 ) 2 ]OH 0.4 mL. In dispersion C, Fe 3 o 4 The particle concentration is 2.5 mg / L, the ascorbic acid concentration is 2 mmol / L, [Ag(NH 3 ) 2 ]OH concentration is 0.2 mmol / L. At a temperature of 25 °C, the dispersion C was reacted for 30 min under constant stirring. After the reaction, the product was collected with a magnet and washed three times with distilled water to obtain Fe with a spherical core-shell structure. 3 o 4 / Ag composites.

[0031] The aforementioned stirring refers to mechanical stirring using a propeller stirrer.

...

Embodiment 3

[0037] According to the invention patent "a magnetic surface-enhanced Raman spectroscopy substrate and its preparation method" (application publication number: CN104034715A), the surface-enhanced Raman spectroscopy substrate is prepared. The substrate is made of Fe with a core-shell structure 3 o 4 / Ag particles are piled up and have a flower-like structure. The optimized preparation method is as follows: dissolve 0.54 g of ferric chloride hexahydrate, 1.176 g of sodium citrate dihydrate, and 0.36 g of urea in 40 mL of distilled water, and then add 0.3 g polyacrylamide, stir until it is completely dissolved; transfer the above solution to a 50 mL reaction kettle lined with polytetrafluoroethylene, seal it and place it in a blast drying oven, and react at 200°C for 8 h; Cool to room temperature, collect the black precipitate with a magnet, wash with distilled water for 3 times, then wash with absolute ethanol for 3 times, and dry in a vacuum oven at 60°C for 8 hours to obtain F...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com