High-performance water-based wood coating

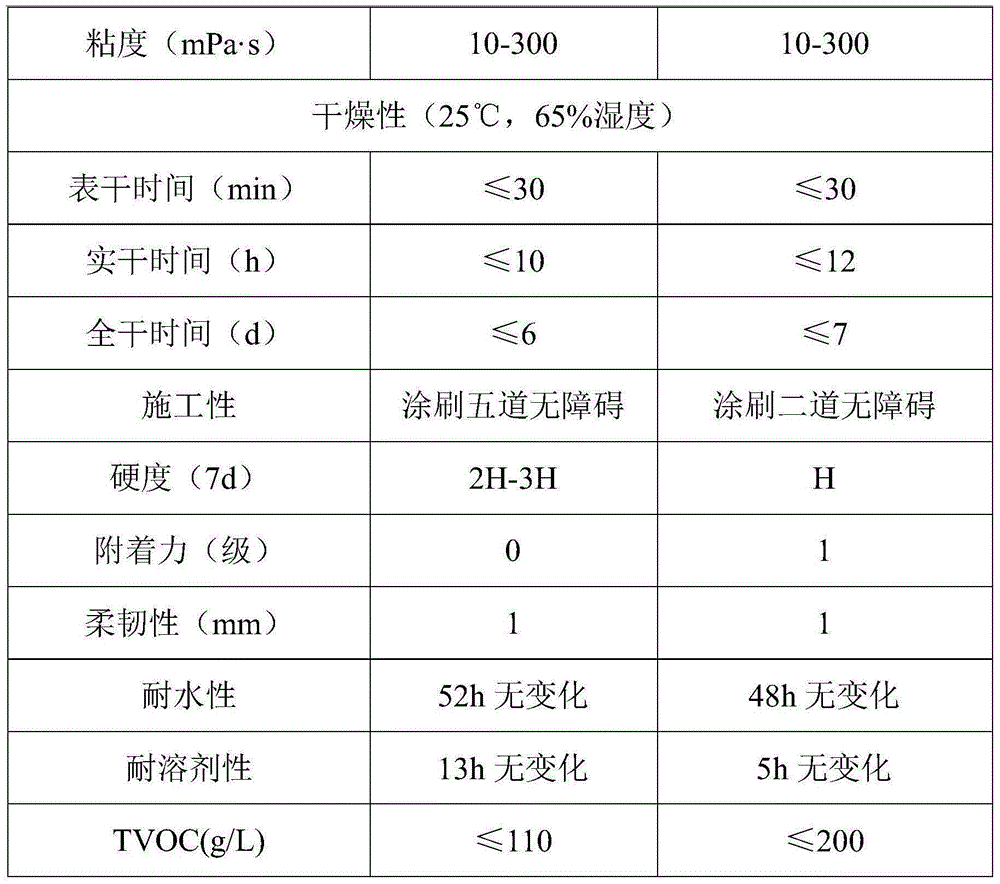

A woodware coating and high-performance technology, applied in the field of coatings, can solve the problems of insufficient water-based woodware coatings, such as insufficient waterproofness, strength, antibacterial property, and wear resistance, etc. the harmful effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The high-performance water-based wood coating of the present invention, its raw material comprises the following components by weight: 50 parts of silica sol-acrylic polyurethane composite emulsion, 5 parts of nano-alumina, 1 part of nano-zinc oxide, 0.25 part of polytetrafluoroethylene, bamboo charcoal 1 part of powder, 3 parts of bentonite, 121 parts of alcohol ester, 3 parts of tripropylene glycol n-butyl ether, 0.1 part of 2,2,4-trimethyl-1,3-pentanediol monoisobutyrate, 2-amino- 0.3 part of 2-methyl-1-propanol, 0.1 part of silane coupling agent, 1 part of defoamer, 0.5 part of thickener, 20 parts of water.

Embodiment 2

[0023] The high-performance water-based wood coating of the present invention, its raw material comprises the following components by weight: 75 parts of silica sol-acrylic polyurethane composite emulsion, 1 part of nano-alumina, 5 parts of nano-zinc oxide, 0.1 part of polytetrafluoroethylene, bamboo charcoal 3 parts of powder, 0.5 parts of bentonite, 122.5 parts of alcohol ester, 1.5 parts of tripropylene glycol n-butyl ether, 0.8 parts of 2,2,4-trimethyl-1,3-pentanediol monoisobutyrate, 2-amino- 0.1 part of 2-methyl-1-propanol, 0.5 part of silane coupling agent, 0.1 part of defoamer, 3 parts of thickener, 5 parts of water;

[0024] Wherein, the silica sol-acrylic polyurethane composite emulsion is prepared according to the following process: add isophorone diisocyanate and polycarbonate diol into the reaction device, heat up to 65°C after nitrogen gas is introduced, stir and keep warm for 5h, and cool down After reaching 55°C, add a mixture of dimethylolpropionic acid, penta...

Embodiment 3

[0026] The high-performance water-based wood coating of the present invention, its raw material comprises the following components by weight: 65 parts of silica sol-acrylic polyurethane composite emulsion, 3.5 parts of nano-alumina, 2.5 parts of nano-zinc oxide, 0.23 part of polytetrafluoroethylene, bamboo charcoal 1.8 parts of powder, 2.1 parts of bentonite, 121.5 parts of alcohol ester, 2.8 parts of tripropylene glycol n-butyl ether, 0.3 parts of 2,2,4-trimethyl-1,3-pentanediol monoisobutyrate, 2-amino- 0.21 parts of 2-methyl-1-propanol, 0.3 parts of silane coupling agent, 0.8 parts of defoamer, 1.2 parts of thickener, 15 parts of water;

[0027] Wherein, the average particle diameter of the nano-alumina is 20nm; the average particle diameter of the nano-zinc oxide is 15nm; the thickener is methyl cellulose;

[0028] The silica sol-acrylic polyurethane composite emulsion is prepared according to the following process: add isophorone diisocyanate and polycarbonate diol into t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com