Method for preparing super capacitor on basis of three-dimensional porous graphene composite material

A technology of supercapacitors and composite materials, applied in the manufacture of hybrid capacitor electrodes, hybrid/electric double layer capacitors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

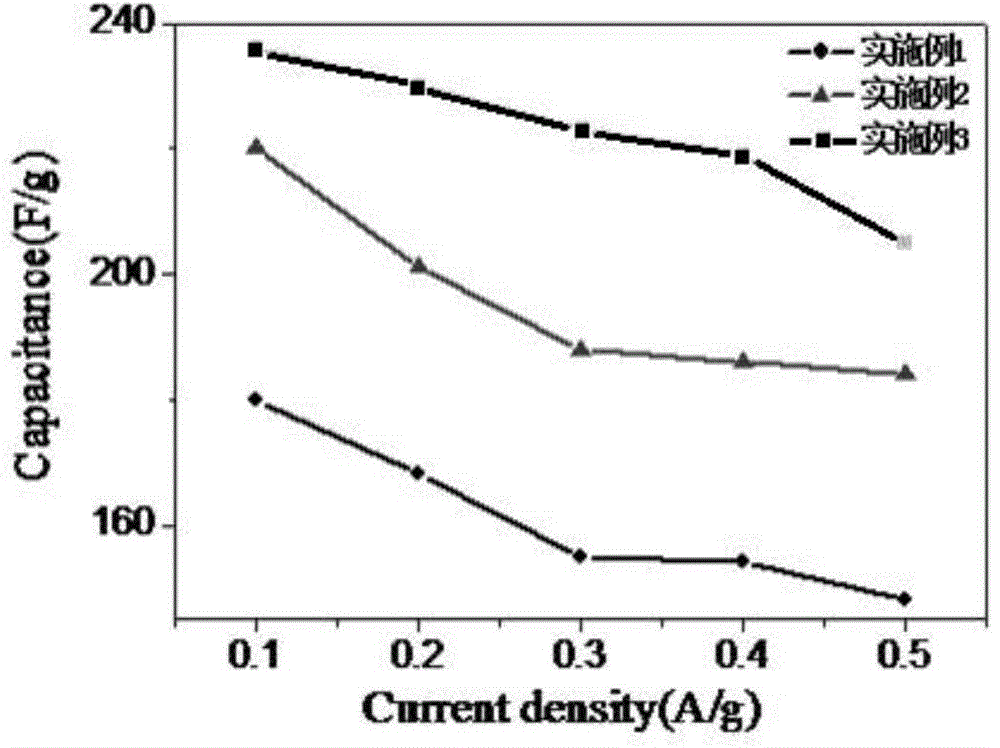

Embodiment 1

[0031] (2) Take 0.03 mol sodium dicotate in advance in 100ml distilled water, and then add 0.25mol NaOH aquatic solution to fully react under strong stirring, and then add an appropriate amount of distilled water to make a mixed slurry C;

[0032] (3) Under the condition of constantly stirring mixing slurry C, adding aquatic solution A and aquatic solution B to the mixed pulp C;

[0033] (4) After adding the addition, the pH value of NAOH solution with a mass ratio of 30%is 9.0 to obtain the sample; put the sample at 80 ° C for 12 hours;

[0034] (5) Wash the samples of Chen Hua to pH = 7, filter, and dry the obtained filter cake within 80 ° C temperature.

[0035] (6) Place the tiny stones of Ding Diexic acid roots in a tube furnace, burn it under the protection of the salamander, heat up to 1000 ° C, and then heat the temperature for 3 hours, then cool down and cool to room temperature to get rough products;

[0036] (7) After removing impurities with exfoliating coarse products...

Embodiment 2

[0045] (2) Take 1.7 mol's sodium dulate sodium sodium sodium sodium sulfonate in 100 ml of distilled water, this is solution C;

[0046] (3) Under the condition of constantly stirring solution C, the aqueous solution A and aquatic solution B are dripped into the solution C;

[0047] (4) After the addition of the drop is completed, the pH value of the NAOH solution with a mass ratio of 30%is 8.0 to obtain the sample; put the sample at 70 ° C for 16 hours;

[0048] (5) Wash the samples of Chen Hua to pH = 7, filter, and dry the obtained filter cake within 60 ° C temperature.It

[0049] (6) Place the water slippery stone plugged in the root of the duoline benzene sulfonic acid in the tube furnace, burn it under the protection of nitrogen, heat up to 800 ° C, then heat the temperature for 6 hours, then cool down and cool to room temperature to get rough products to obtain rough productsIt

[0050] (7) After removing impurities with exfoliating coarse products, the vacuum drying materi...

Embodiment 3

[0058] (2) Take 0.01mol's special -grade pure rosin fully scattered in 100ml water -free ethanol, this is solution C;

[0059] (3) Under the condition of constantly stirring solution C, the aqueous solution A and aquatic solution B are dripped into the solution C;

[0060] (4) After adding the addition, the pH value of NAOH solution with a mass ratio of 30%is 11.0 to obtain the sample; put the sample at 90 ° C for 10 hours;

[0061] (5) Wash the samples of Chen Hua to pH = 8, filter, and dry the obtained filter cake within 100 ° C temperature.

[0062] (6) Put the rosin roots in the tube furnace, burn it under the protection of the salamander, heat up to 1500 ° C, and then heat the temperature for 1 hour, then cool down and cool to room temperature to get rough products;

[0063] (7) After removing impurities with exfoliating coarse products, the vacuum drying material with a three-dimensional porous structure at 80 ° C is obtained;Up to 1810M 2 / g, single -point Kong Rong (P / P0 =...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com