Method for processing dried blueberry fruit having high anthocyanin content

A processing method and high anthocyanin technology are applied in food processing, fruit and vegetable preservation, and the function of food ingredients, etc., which can solve the problems of anthocyanin substance destruction, product phase difference, nutrition and functional health discount, etc., and achieve Effect of reducing loss and inhibiting hydration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

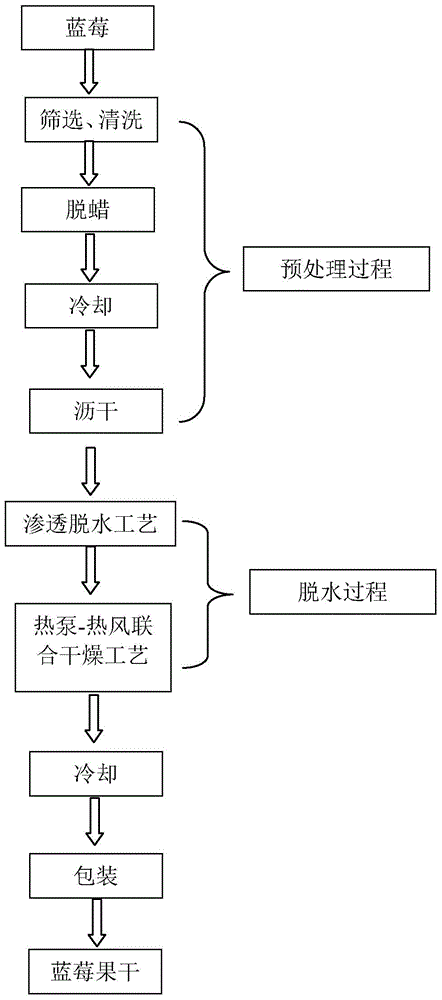

[0032] After screening and washing the blueberries, drain the water, prepare a 0.10% citric acid solution (pH<4.0), blanch at 95°C for 50s, quickly cool the blanched blueberries with cold water to below 35°C, and drain the surface water. The blueberries were immersed in a fructose syrup solution of 65°Brix at a ratio of 1:1.5 by mass to liquid, and 0.15% of honey, 0.10% of seaweed polysaccharide, 0.10% of citric acid, 0.03 % ascorbic acid, 0.04% tartaric acid, 0.01% tannic acid, 0.04% tea polyphenols, osmotic dehydration at 35°C for 48h, and 35% of fresh fruit moisture was removed. The blueberries after osmotic dehydration are dried to a moisture content of 35% by using a heat pump drying method at 42 ° C and a humidity of 60%, and then dried by a hot air drying method at 55 ° C until the moisture content is less than 15%, and aw is less than 0.65. The dried blueberry fruit is cooled to room temperature, and then packed in an opaque aluminum foil bag to obtain the dried bluebe...

Embodiment 2

[0034] After screening and washing the blueberries, drain the water, prepare a 0.15% citric acid solution (pH<4.0), blanch at 98°C for 45s, quickly cool the blanched blueberries with cold water to below 35°C, and drain the surface water. The blueberries were immersed in the fructose syrup solution of 55°Brix according to the ratio of material to liquid mass ratio of 1:2.0, and the mass fractions of 0.15% honey, 0.15% seaweed polysaccharide and 0.05% citric acid were added to the dipping solution. , 0.06% ascorbic acid, 0.03% tannic acid, 0.08% tartaric acid, 0.06% tea polyphenols, osmotic dehydration at 40 ℃ for 60h, removing 32% of fresh fruit moisture. The blueberries after osmotic dehydration are dried to a moisture content of 30% by a heat pump drying method at 45°C and a humidity of 65%, and then dried by a hot air drying method at 53°C to a moisture content of less than 15% and aw less than 0.65. The dried blueberry dried fruit is cooled to room temperature, and packed i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com