Ethanol diesel oil

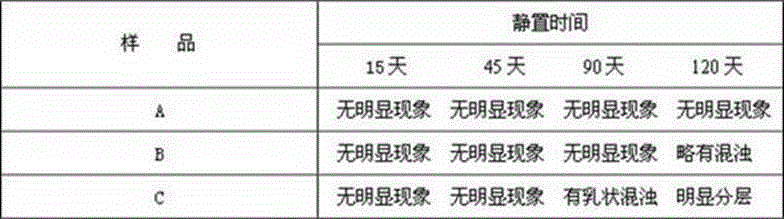

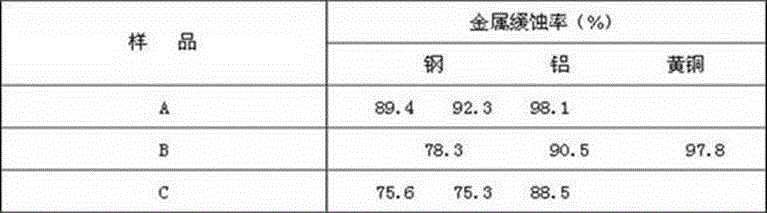

A technology of ethanol diesel and diesel oil, which is applied in the field of fuel oil, can solve the problems of poor stability and easy stratification of high-proportion ethanol diesel, and achieve the effects of protecting metal surfaces, reducing friction, and delaying corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Take the following raw materials by weight ratio:

[0026] Diesel 60 parts

[0027] 15 parts ethanol

[0028] Hydroxycyclohexanebenzophenone 1.0 parts

[0029] 1.5 parts of methylcyclopentane

[0030] 3.0 parts of methyl tert-amyl ether dimethyl ether

[0031] Lauryl methacrylate 1.5 parts

[0032] Sorbitan monolaurate 4.0 parts

[0033] Alkylphenol formaldehyde resin polyoxyethylene ether 2.5 parts

[0034] Phytate 1.0 parts

[0035] Cetyl dimethyl ammonium chloride 1.0 parts

[0036] Dimethoxypropane 0.5 part

[0037] First add hydroxycyclohexanebenzophenone, methylcyclopentane, methyl tert-amyl ether dimethyl ether into the raw material mixing tank, stir well and mix well, let stand naturally for 20-30 minutes, then add methacrylic acid Lauryl ester, sorbitan monooleate, stirred at normal temperature and pressure for 15-20 minutes, then added alkylphenol formaldehyde resin polyoxyethylene ether, phytic acid ester, stirred for 20-30 minutes; then Add cetyl d...

Embodiment 2

[0039] Take the following raw materials by weight ratio:

[0040] Diesel 60 parts

[0041] 20 parts ethanol

[0042] Hydroxycyclohexanebenzophenone 4.0 parts

[0043] Methylcyclopentane 3.0 parts

[0044] 1.0 parts of methyl tert-amyl ether dimethyl ether

[0045] Lauryl methacrylate 5.0 parts

[0046] Sorbitan monolaurate 2.5 parts

[0047] Alkylphenol formaldehyde resin polyoxyethylene ether 1.0 parts

[0048] Phytate 3.0 parts

[0049] Cetyl dimethyl ammonium chloride 2.5 parts

[0050] Dimethoxypropane 2.0 parts

[0051] First add hydroxycyclohexanebenzophenone, methylcyclopentane, methyl tert-amyl ether dimethyl ether into the raw material mixing tank, stir well and mix well, let stand naturally for 20-30 minutes, then add methacrylic acid Lauryl ester, sorbitan monooleate, stirred at normal temperature and pressure for 15-20 minutes, then added alkylphenol formaldehyde resin polyoxyethylene ether, phytic acid ester, stirred for 20-30 minutes; then Add cetyl dim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com