A kind of sulfate-reducing bacteria immobilized particle and its preparation and use method

A sulfate, particle technology, applied in chemical instruments and methods, immobilized on or in inorganic carriers, immobilized on/in organic carriers, etc., can solve the problems of low pH, utilization rate of less than 30%, etc., To achieve the effect of reducing the COD value of effluent, improving the treatment capacity and improving the utilization rate of carbon sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

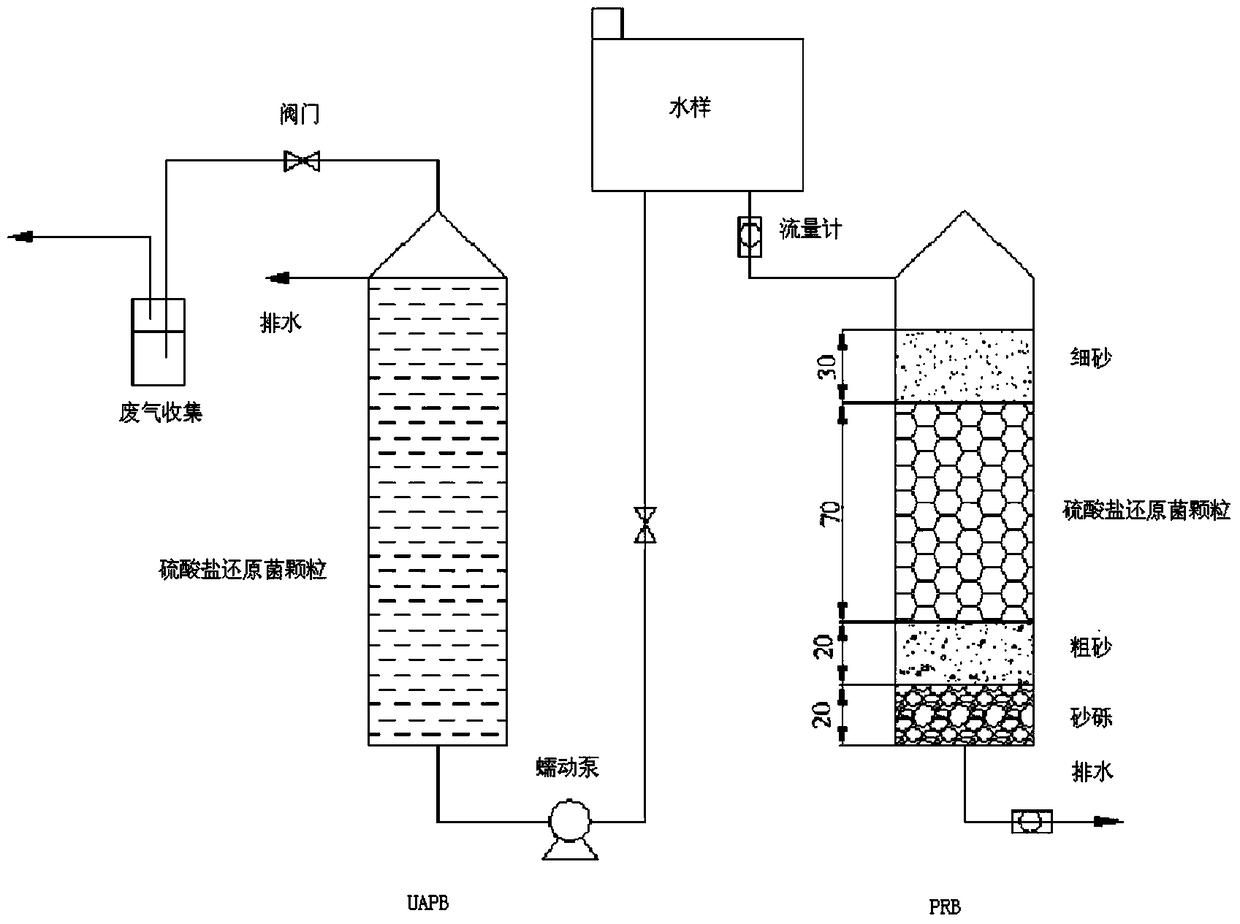

Image

Examples

preparation example Construction

[0037] The preparation method of the sulfate-reducing bacteria sludge stock solution is as follows: sulfate-reducing bacteria raw materials such as municipal activated sludge, landfill leachate sludge, and coal gangue polluted soil containing sulfate-reducing bacteria and hydrolytic microorganisms are diluted 10-20 times Take out 25mL-50mL and add it to 500mL-1000mL improved Starkey-type culture medium, and anaerobic culture at a constant temperature of 37±1℃ for several weeks to form sulfate-reducing bacteria as the dominant bacteria in the sludge, including hydrolytic microorganisms A mixed sulfate-reducing bacteria sludge floc that coexists with a variety of microbial strains; when the bottle cap is opened after cultivation, a strong smell of rotten eggs can be smelled, and the sludge suspension is dripped into the 2+ When the solution can immediately turn the solution into ink color, the sludge stock solution of sulfate-reducing bacteria is obtained;

[0038] The compositi...

Embodiment 1

[0041] A sulfate-reducing bacteria immobilized particle, the weight percentage of each component is: 30% sulfate-reducing bacteria sludge, 2% steel slag powder, 3% modified medical stone, 9% polyethylene alcohol, 0.5% sodium alginate, 5% corn cob and 50.5% water.

[0042] Its preparation method is:

[0043] Choose steel slag powder with a particle size of 80 mesh, wash it 3 times with 1mol / L HCl, and air-dry it; choose ordinary medical stone powder with a particle diameter of 60 mesh, use 2mol / L NaOH solution and medical stone powder according to the volume-to-mass ratio of 1:5kg / L mixed, soaked for 1 hour, then oscillated at 150r / min for 3 hours, then took out the medical stone, soaked it with deionized water for 3 times, baked at 300°C for 90 minutes, and cooled naturally to obtain Modified medical stone; corn cobs are dried in the sun and crushed mechanically to make a powder with a particle size of 100 mesh;

[0044] Add 9g of polyvinyl alcohol and 0.5g of sodium alginat...

Embodiment 2

[0050] A sulfate-reducing bacteria immobilized particle, the weight percentage of each component is: 20% sulfate-reducing bacteria sludge, 6% steel slag powder, 10% medical stone, 5% polyvinyl alcohol, 0.2% sodium alginate, 4% peanut shells and 54.8% water.

[0051] Its preparation method is:

[0052] Select steel slag powder with a particle size of 90-100 mesh, wash 2-3 times with 2mol / L HCl, and air-dry; select ordinary medical stone powder with a particle size of 70-80 mesh, wash with water 2-3 times, and air-dry; take peanut shells After drying, it is mechanically crushed to make a powder with a particle size of 80-100 mesh;

[0053] Add 5g of polyvinyl alcohol and 0.2g of sodium alginate into 54.8g of distilled water, fully swell at room temperature for 20 hours after sealing, then heat in a constant temperature water bath at 94±1°C, and keep stirring until there are no bubbles in the gel ;

[0054] Then slowly add 4g of biomass material peanut shell powder, 6g of stee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com