Polyurethane material for adsorbing TGF-B1 growth factor for tissue repair and preparation method thereof

A polyurethane material, TGF- technology, applied in medical science, prosthesis and other directions, can solve the problems of complex preparation method, achieve the effect of simple and convenient preparation process, improve tissue repair effect, and reduce release speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

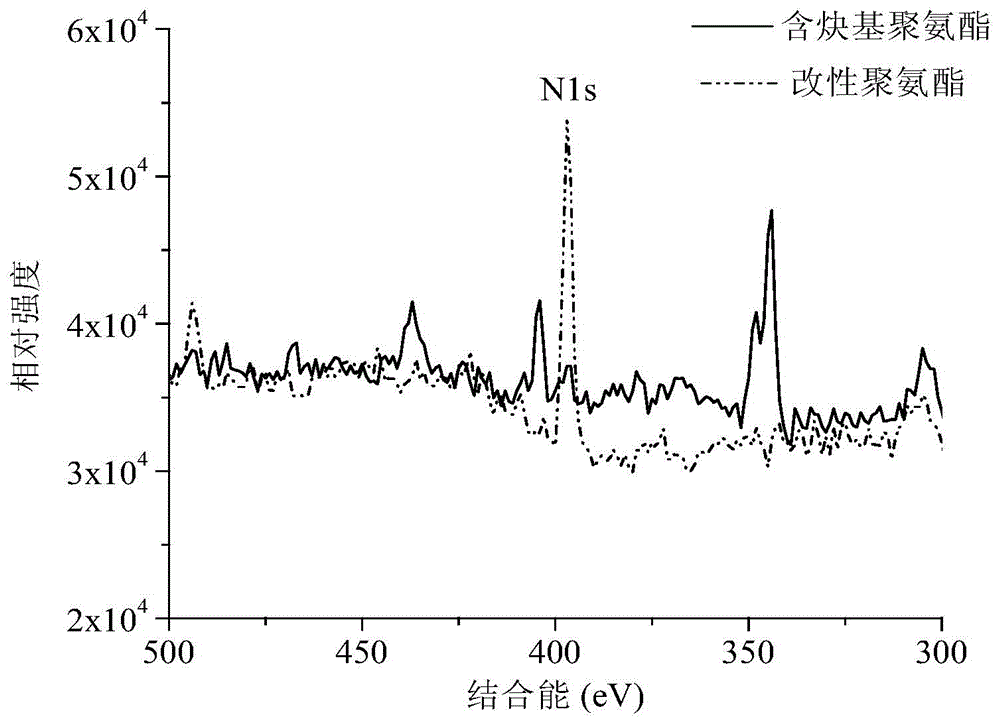

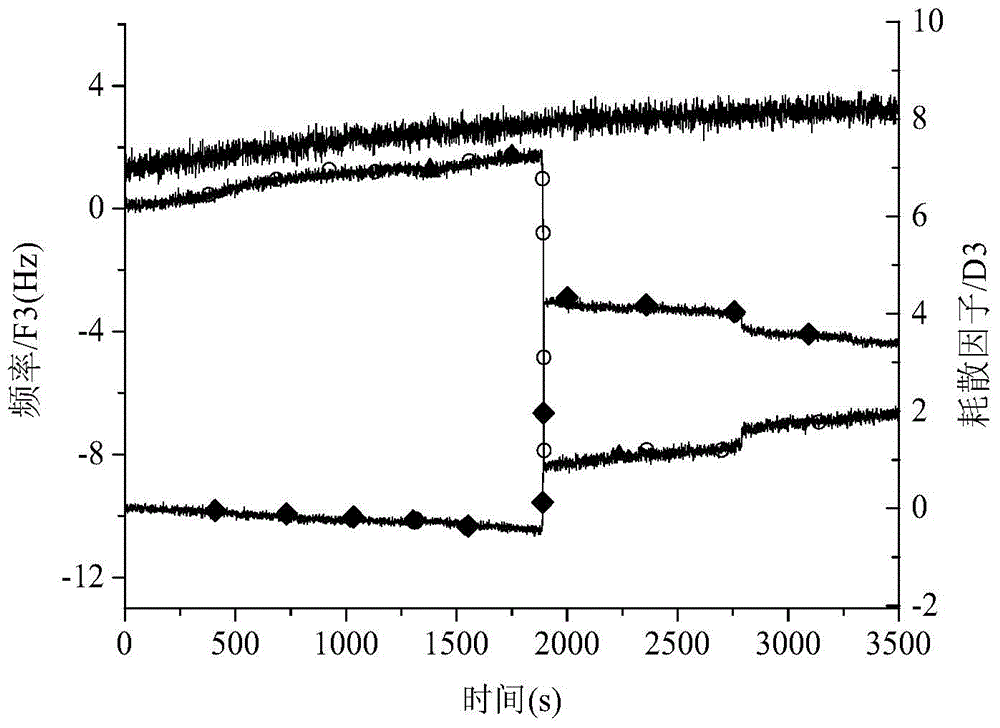

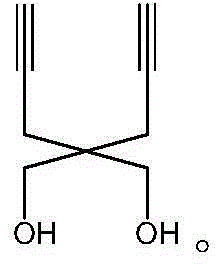

[0035] Weigh 20g of PCL-2000 in a three-necked flask, dehydrate under vacuum at 100°C for 30min (1mbar), add 100ml of DMF, 3.36g of HDI and 0.005g of stannous octoate catalyst under a nitrogen atmosphere, then cool down to 80°C for 2.5 h to form a prepolymer. After the prepolymer was formed, 1.52 g of chain extender DPPD was added. After raising the reaction temperature to 110°C, the reaction was continued for 4 hours, and water was added to terminate the reaction. After drying, it was purified by co-precipitation with methanol to obtain an alkyne-containing polyurethane. Finally, in the mixed solution of anhydrous copper sulfate (2mol%) and sodium ascorbate (10mol%), the azide-modified HSNGLPL is grafted to the surface of polyurethane synthesized by "click chemistry" reaction, and the system ambient oxygen concentration≤10ppm, the reaction The time is 12 hours, and a surface-modified polyurethane material is obtained, which can specifically adsorb TGF-β1 growth factor.

[0...

Embodiment 2

[0044]Weigh 5g of PEG-500 in a three-necked flask, dehydrate at 100°C for 30min under vacuum (1mbar), add 20ml of DMF, 2.75g of MDI and 0.2g of stannous octoate catalyst under nitrogen atmosphere, then cool down to 60°C for 4h to form a prepolymer. After the prepolymer was formed, 0.15 g of DPPD was added. Continue to react at 60°C for 24h, add water to terminate the reaction, and purify with methanol co-precipitation after drying. Finally, in the mixed solution of anhydrous copper sulfate (5mol%) and sodium ascorbate (10mol%), the azide-modified HSNGLPL is grafted to the surface of the synthetic polyurethane by "click chemistry" reaction, the system ambient oxygen concentration≤10ppm, the reaction time After 36 hours, a functionalized polyurethane material that specifically adsorbs TGF-β1 growth factor was obtained.

[0045] The performance of the functionalized polyurethane material specifically adsorbing TGF-β1 growth factor obtained in this example is similar to that of ...

Embodiment 3

[0047] Weigh 10g of PTMG-1000 in a three-necked flask, dehydrate at 100°C for 30min (1mbar) under vacuum, add 50ml of DMF, 5.22g of TDI and 0.005g of triethylamine catalyst under nitrogen atmosphere, then cool down to 90°C for 1h to form a prepolymer. After the prepolymer was formed, 3.04 g of DPPD was added. After raising the reaction temperature to 100° C., the reaction was continued for 5 h, and water was added to terminate the reaction. After drying, it was purified by co-precipitation with methanol. Finally, the azide-modified HSNGLPL was grafted onto the surface of the synthesized polyurethane by "click chemistry" reaction. A functionalized polyurethane material capable of specifically adsorbing TGF-β1 growth factor is obtained.

[0048] The performance of the functionalized polyurethane material specifically adsorbing TGF-β1 growth factor obtained in this example is similar to that of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com