Preparation method for polycarboxylate superplasticizer

A technology of water reducing agent and polycarboxylic acid, applied in the field of preparation of polycarboxylic acid water reducing agent, can solve the problems of high pollution, increased production cost, high energy consumption, etc., and achieves less equipment investment, stable product performance, and operation easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

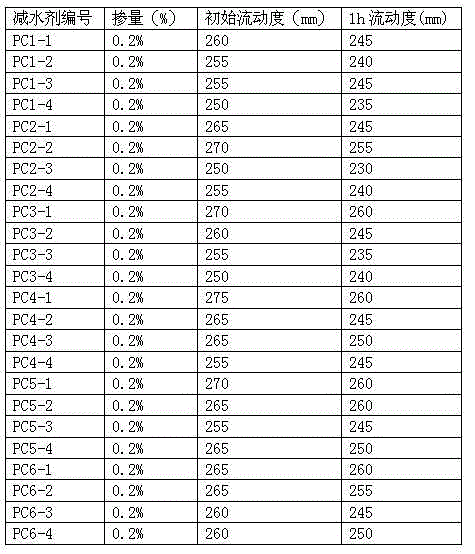

Examples

Embodiment 1

[0022] a Prepare the configuration of the initiator

[0023] Add 100g of vitamin C to the container, add water to dissolve, then add 1g of trisodium phosphate and 80g of sodium allyl sulfonate, continue to add water to dissolve, and configure it into a Y solution with a mass concentration of 5%. Store them for 7 days, 15 days, 30 days, and 50 days respectively, and mark them as Y1-1, Y1-2, Y1-3, and Y1-4.

[0024] b Initiator initiates synthesis of polycarboxylate superplasticizer

[0025] Add 500g of allyl polyoxyethylene ether to the reaction vessel, add 2500g of water at the same time, stir at room temperature until completely dissolved, then add 1g of hydrogen peroxide, 50g of acrylic acid, and 5g of Y solution, and then continue to stir and react for 1.0 hours, using a mass concentration of 30% The sodium hydroxide solution is adjusted to make it PH=7, and the gained transparent liquid is the target product polycarboxylic acid.

[0026] Replace Y with Y1-1, Y1-2, Y1-3, ...

Embodiment 2

[0028] a Prepare the configuration of the initiator

[0029] Add 100g of sodium bisulfite to the container, add water to dissolve, then add 5g of mercaptopropionic acid and 40g of sodium methallylsulfonate, continue to add water to dissolve, and configure it into a Y solution with a mass concentration of 7%. Store them for 7 days, 15 days, 30 days, and 50 days respectively, and mark them as Y2-1, Y2-2, Y2-3, and Y2-4.

[0030] b Initiator initiates synthesis of polycarboxylate superplasticizer

[0031] Add 500g of sodium methallyl sulfonate to the reaction vessel, add 1000g of water at the same time, stir at room temperature until completely dissolved, then add 2g of potassium oxalate, 25g of lactic acid, and 8g of Y solution, and then continue to stir and react for 1.5 hours.

[0032] Use a sodium hydroxide solution with a mass concentration of 40% to adjust the pH to 6, and the resulting transparent liquid is the target product polycarboxylic acid.

[0033] Replace Y with ...

Embodiment 3

[0035] a Prepare the configuration of the initiator

[0036] Add 100g of hanging white cubes to the container, add water to dissolve, then add 1.5g of thioglycolic acid, 60g of 2-acrylamido-2 methylpropanesulfonic acid, continue to add water to dissolve, and configure it to a mass concentration of 10%. solution. Store them for 7 days, 15 days, 30 days, and 50 days respectively, and mark them as Y3-1, Y3-2, Y3-3, and Y3-4.

[0037] b Initiator initiates synthesis of polycarboxylate superplasticizer

[0038] Add 500g of allyl polyoxyethylene ether to the reaction vessel, add 1500g at the same time, stir at room temperature until completely dissolved, then add 2g of hydrogen peroxide, 40g of maleic anhydride, and 6g of Y solution, and then continue to stir for 1.5 hours. % sodium hydroxide solution is adjusted to make it PH=6, and the gained transparent liquid is the target product polycarboxylic acid.

[0039] According to the above, replace Y with Y3-1, Y3-2, Y3-3, Y3-4 resp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com