Preparation method of SU-8 photoresist-based three-dimensional microelectrode

A SU-8, photoresist technology, applied in circuits, capacitors, electrical components, etc., can solve the problems of small specific surface area of supercapacitor electrodes, and achieve the effect of facilitating mass production, increasing specific surface area, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

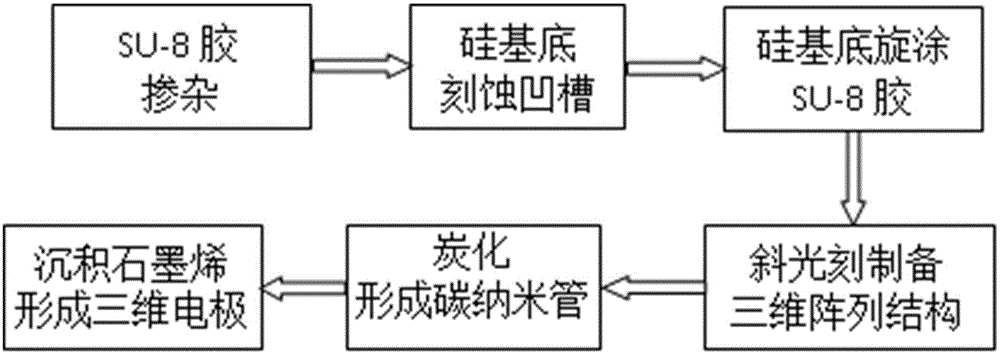

[0022] The process flow of the three-dimensional microelectrode preparation method based on SU-8 photoresist of the present invention is as follows figure 1 As shown, the manufacturing steps are as follows:

[0023] Grind ferric chloride into particles with a particle size greater than 2nm and less than 50nm, then mix and stir with SU-8 photoresist evenly, and then remove ferric chloride by high-temperature sublimation in the carbonization step to effectively control the pore size;

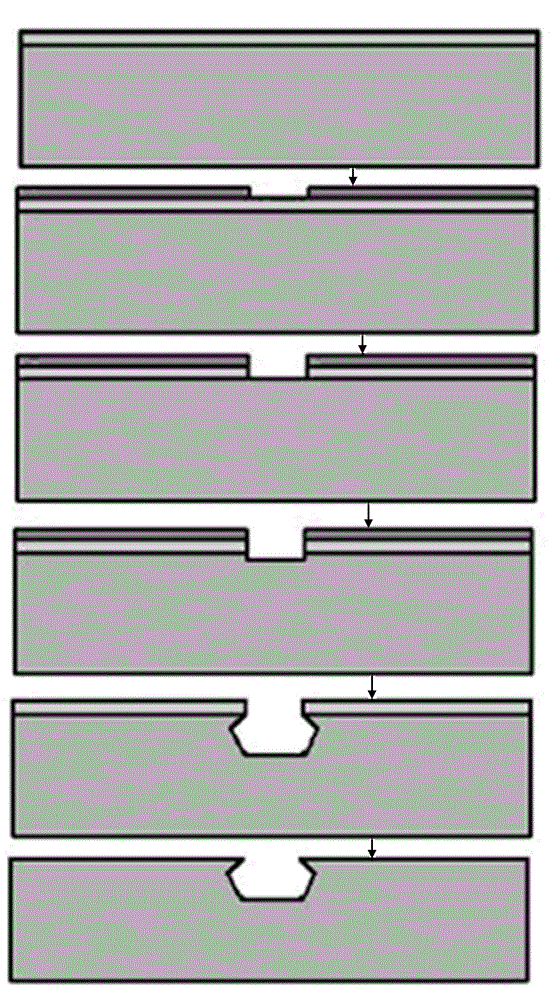

[0024] Select a 2-inch silicon wafer as the substrate, and wash the silicon wafer substrate in acetone, alcohol, sulfuric acid / hydrogen peroxide, ammonia water / hydrogen peroxide, hydrochloric acid / hydrogen peroxide solution to remove oil stains, oxide films and metal ions. After standard cleaning of the silicon wafer substrate, as image 3 As shown, the groove structure of "narrow mouth and wide inside" is etched on the silicon wafer substrate to prevent the SU-8 carbon nanotubes obtained after ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com