Hybrid membrane production method

A hybrid film, compound technology, applied in semiconductor/solid state device manufacturing, nanotechnology for materials and surface science, electrical components, etc., can solve the problem of poor repeatability of hybrid materials, limiting composite film mobility, polymer Poor stability and other problems, to achieve the effect of easy large-scale mass production, low cost, and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

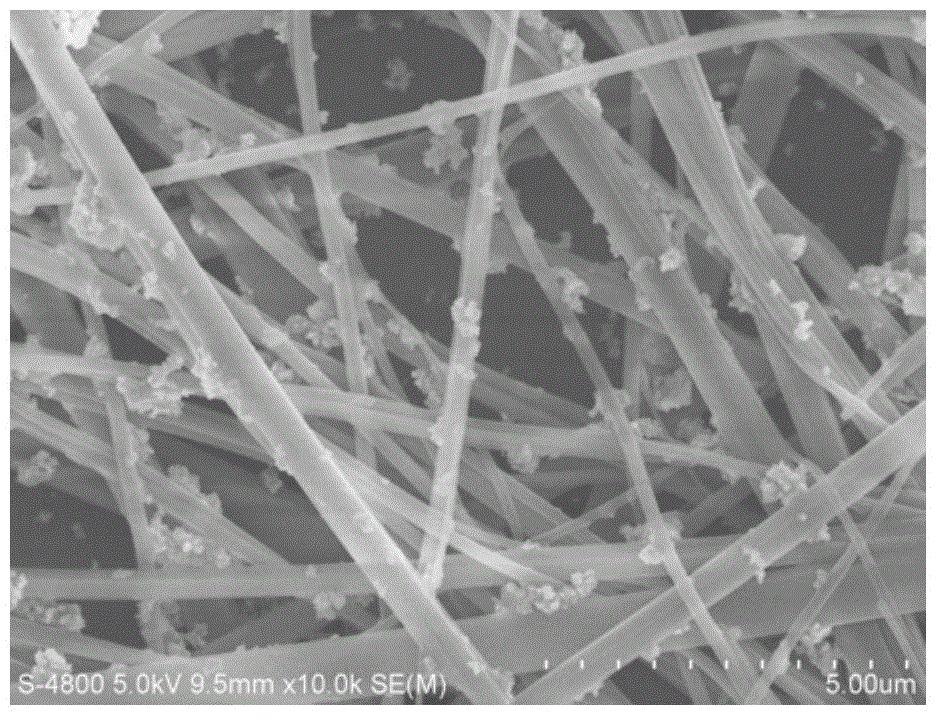

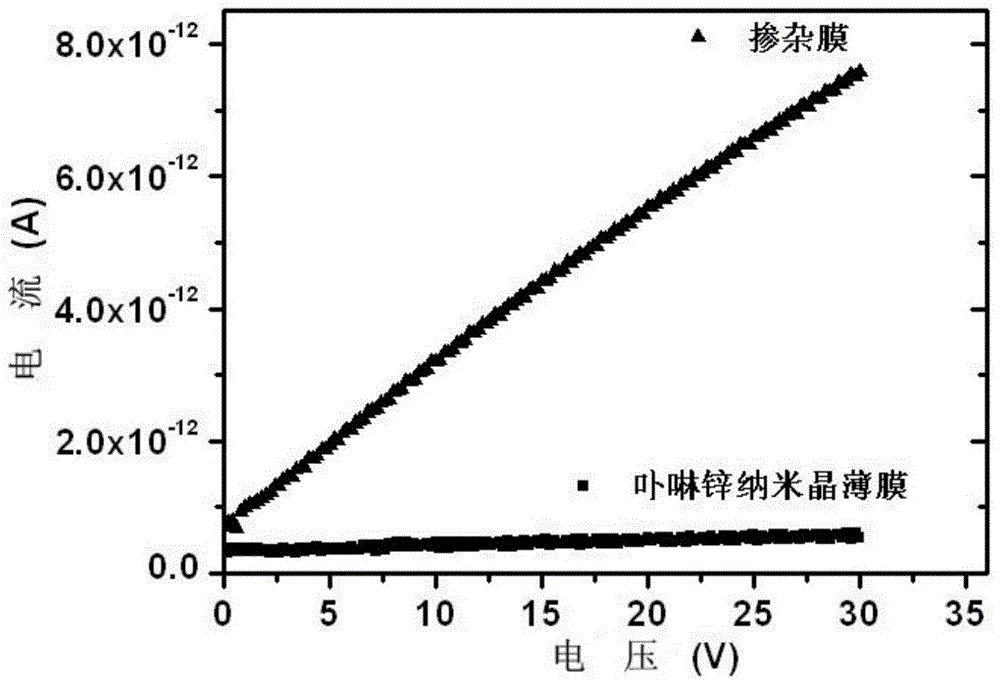

[0037] In the hybrid film of this embodiment, the organic semiconductor material in the raw material is zinc porphyrin, the first solvent is chloroform and octane, and the ratio of chloroform and octane is 4:1; the inorganic nanomaterial is zinc oxide, and the second solvent is ethanol .

[0038] The preparation method of this hybrid film comprises the following steps:

[0039] Step 1: Dissolve zinc porphyrin in the mixture of chloroform and octane to form the first mixture with a concentration of zinc porphyrin of 1 mg / mL; disperse zinc oxide in ethanol and disperse evenly by ultrasonic to form a zinc oxide concentration of 0.5 mg / mL of the second mixture. Among them, the solubility of porphyrin zinc in different solvents is different, and it affects the quality of subsequent nanocrystal assembly ability. Those skilled in the art know that for metal phthalocyanine compounds or metal porphyrin compounds themselves, the solubility in organic solvents is not high, so in order ...

Embodiment 2

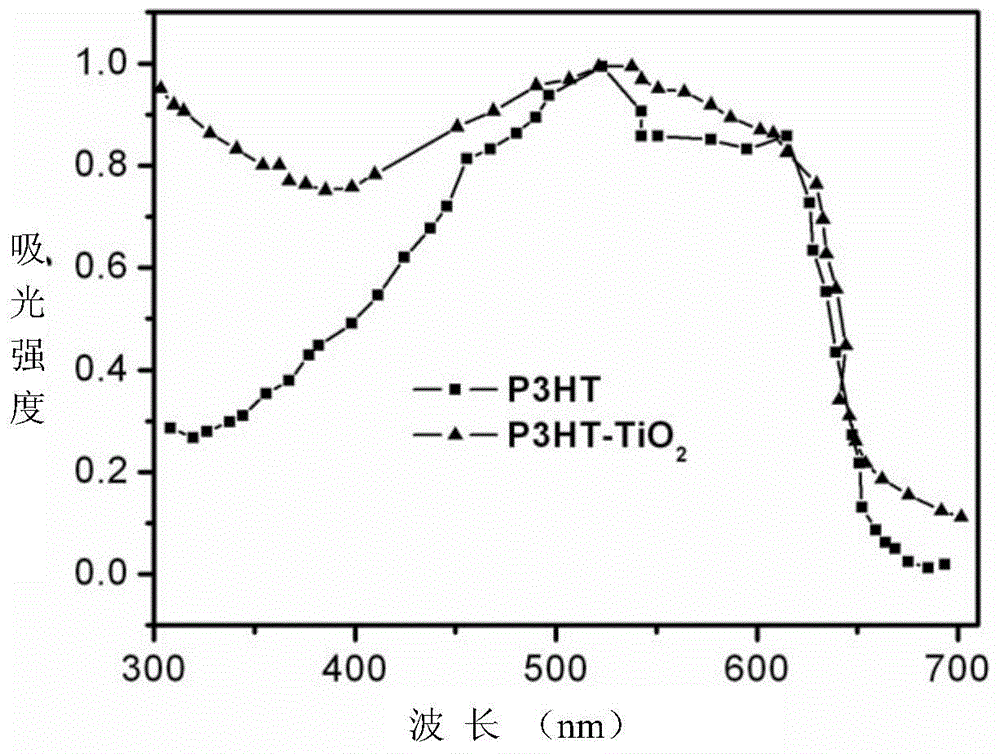

[0045] In the hybrid film of this embodiment, the organic semiconductor material is cobalt octamethylporphyrin, the first solvent is chlorobenzene; the inorganic nano material is titanium dioxide, and the second solvent is water.

[0046] Step 1: dissolving cobalt octamethylporphyrin in the chlorobenzene mixture to form the first mixture with a cobalt octamethylporphyrin concentration of 2 mg / mL; disperse titanium dioxide in distilled water and disperse evenly by ultrasonic to form a concentration of titanium dioxide of 0.2 mg / mL of the second mixture.

[0047] Step 2: Transfer the first mixture to the inert substrate SiO by spin coating 2 On the substrate, let stand at room temperature for 40 minutes, and then anneal at 120° C. for 30 minutes, and form cobalt octamethylporphyrin cobalt nanocrystals after the chlorobenzene volatilizes. Wherein, the annealing treatment in this step is to allow the chlorobenzene solvent to evaporate faster and clean.

[0048] Step 3: Soak the ...

Embodiment 3

[0050] In the hybrid film of this embodiment, the organic semiconductor material in the raw material is perylene imide, the first solvent is chloroform and methanol, and its volume ratio is about 1:5; the inorganic nanomaterial is silver nanoparticles, and the second solvent is ethanol.

[0051] Step 1: dissolving peryleneimide in a mixture of chloroform and methanol to form the first mixture with a peryleneimide concentration of 0.2 mg / mL; dispersing silver nanoparticles in ethanol and ultrasonically dispersing them uniformly to form silver nanoparticles A second mixture at a concentration of 0.5 mg / mL. For compounds such as perylene imide or its derivatives, adjusting its concentration in the first mixture within the range of 0.1-5 mg / mL can stably obtain a nanocrystalline film structure.

[0052] Step 2: Transfer the first mixture to an inert substrate polyethylene terephthalate (PET) substrate by aerosol spray printing, and let it stand at room temperature for 30 minutes, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com