Method for preparing heavy metal extraction agent microcapsule and application of heavy metal extraction agent microcapsule to heavy metal wastewater treatment

An extractant and heavy metal technology, which is applied in the field of preparation of heavy metal extractants, can solve the problems of large differences in polarity and water solubility, difficult industrialization and mass production, and complicated technology, and is conducive to selective adsorption and desorption, maintaining The effect of capsule integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

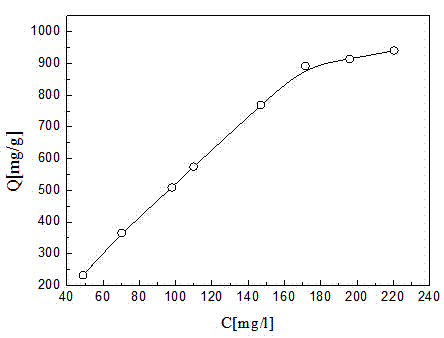

Examples

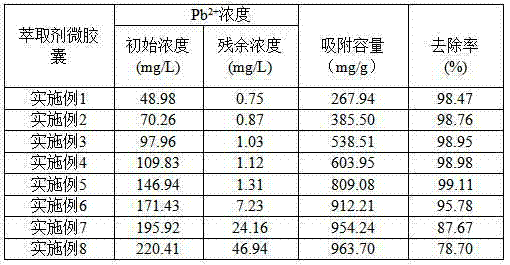

Embodiment 1

[0033] Embodiment 1 adopts the following steps to realize the present invention:

[0034] 1. Preparation of extractant microcapsules:

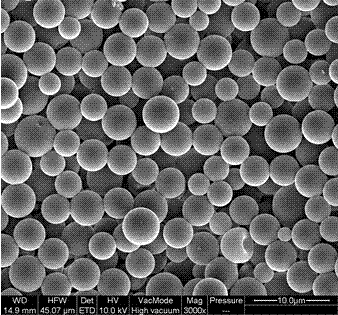

[0035] (1) Preparation of hollow capsules: Take 5g methyl methacrylate, 10g methacrylic acid, 1g tetraethylene glycol dimethacrylate, 0.5g trimethylolpropane trimethacrylate, 0.5g 1-hydroxycyclohexyl For phenyl ketone, the above-mentioned components were stirred evenly, and then slowly added dropwise under stirring to a solution in which 3 g of styrene-maleic anhydride copolymer sodium salt was dissolved in advance, and homogeneously emulsified to obtain an emulsion, and then ultrasonically Ultrasonic cavitation of the emulsion with a frequency of 20KHz for 20 minutes, under stirring, use a UV lamp with a power of 2000w, with a distance of 20cm from the liquid surface, and react with UV light for 15 minutes. After the reaction is completed, add a large amount of water to the suspension obtained from the reaction, and rinse repeatedly Hollow c...

Embodiment 2

[0038] Embodiment 2 adopts the following steps to realize the present invention:

[0039] 1. Preparation of extractant microcapsules:

[0040] (1) Preparation of hollow capsules: Take 3g of styrene, 10g of sodium methacrylate hydroxypropylsulfonate, 1.5g of hexanediol dimethacrylate, 0.3g of pentaerythritol triacrylate, and 0.6g of azobisisobutyronitrile, Stir the above-mentioned components evenly, then slowly drop them into the solution dissolved with 3g of sodium dodecylbenzenesulfonate under stirring, then perform ultrasonic cavitation on the emulsion at an ultrasonic frequency of 40KHz for 10 minutes, and raise the temperature of the above-mentioned emulsion to 75 o C, stirring and reacting for 2 hours, after the reaction is over, add a large amount of water to the suspension obtained by the reaction, repeatedly rinse the hollow capsule particles in the suspension, then collect the floating particles in the upper layer, and dry them in vacuum to obtain hollow microcapsules...

Embodiment 3

[0043] Embodiment 3 adopts the following steps to realize the present invention:

[0044] 1. Preparation of extractant microcapsules:

[0045] (1) Preparation of hollow capsules: Take 3g styrene, 3g methyl methacrylate, 5g methacrylic acid, 5g acrylamide, 1g neopentyl glycol diacrylate, 0.6g trimethylolpropane trimethacrylate, 0.5g of 1-hydroxycyclohexyl phenyl ketone, stir the above-mentioned components evenly, then slowly add dropwise to the solution with 3g of styrene-maleic anhydride copolymer sodium salt under stirring, and then conduct the emulsification of the emulsion with an ultrasonic frequency of 80KHz Ultrasonic cavitation for 10 minutes, under stirring, use a UV lamp with a power of 1000w, with a distance of 30cm from the liquid surface, and react with UV light for 20 minutes. After the reaction is completed, add a large amount of water to the suspension obtained from the reaction, and rinse the hollow capsules in the suspension repeatedly. Particles, then collec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com