A kind of silver-substituting copper-phosphorus-tin solder ring and preparation method thereof

A solder ring and coating technology, which is applied in the direction of manufacturing tools, welding equipment, metal processing equipment, etc., can solve the problems that cannot be used in the production of coating solder, etc., achieve good wetting and spreading properties, and speed up heat conduction , huge social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] Preparation method of the present invention is to adopt following steps to realize:

[0029] a) Melting of copper-phosphorus-tin solder ingot;

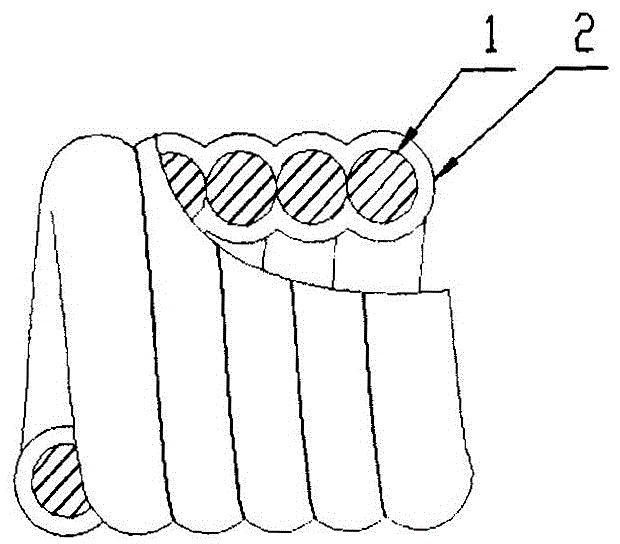

[0030] b) Preparation of filamentous copper-phosphorus-tin solder;

[0031] c) Copper-phosphorus-tin solder wire is wound into a ring shape;

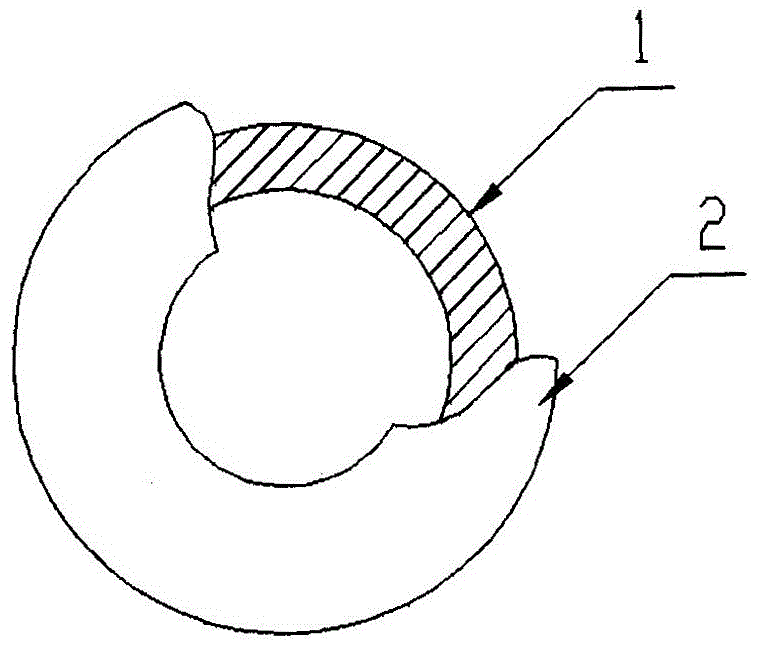

[0032] d) Make a flux liquid with a weight ratio of 50% to 70% of flux, 1% to 5% of adhesive, 1% to 4% of toughening agent, and 20% to 50% of solvent, and then put the flux The liquid is sprayed onto the outside of the ring-shaped copper-phosphorus-tin solder core, and after drying, the coated copper-phosphorus-tin solder ring is made.

[0033] The copper-phosphorus-tin solder ingot in the present invention is prepared from the following raw materials in weight ratio, wherein: P6.8%~7.2%, Sn0.4%~3%, Zr0.02%~0.5%, Si0.01%~0.4%, rare earth 0.01%~0.025%, and the rest is Cu.

[0034] When using the silver-substituting copper-phosphorus-tin-coated solder ring of the present invention to b...

Embodiment 1

[0038]The steps of the preparation method of this example are as follows: a) Prepare Cu, Cu-P master alloy, Sn, Cu-Si master alloy, Zr and rare earth in proportion, melt and cast it into a Φ50 mm rod-shaped BCu90P7Sn2.5ZrSi solder alloy Ingot (alloy composition: 6.8% to 7.2% of P, 0.4% to 3% of Sn, 0.02% to 0.5% of Zr, 0.01% to 0.4% of Si, 0.01% to 0.025% of rare earth, and the rest is Cu ), cut off the riser and then turn the ingot to remove the scale, and set it aside; b) raise the temperature of the solder extrusion equipment system to 460 ℃, place the ingot after turning and remove the scale in the muffle furnace to preheat, The preheating temperature is 470 °C, put the preheated ingot into the mold barrel of the extrusion equipment, extrude it into a Φ1.1 mm brazing wire, and draw it to a Φ0.8 mm silver brazing wire; c ) Clean the drawn copper-phosphorus-tin solder wire with dilute acid and passivate it. After cleaning, put it into the material tray of the ring-making equ...

Embodiment 2

[0040] The difference from Example 1 is that the flux composition is 10% sodium fluorosilicate or potassium fluoroaluminate, 35% potassium fluoride or lithium fluoride, 20% potassium fluoroborate, and 35% boric anhydride. The copper-phosphorus-tin-coated solder described in Example 1 can be used to braze common copper alloys, and this embodiment can be used to braze copper alloys containing aluminum.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com