Preparation method of graphene hydrogel and application of the graphene hydrogel

A graphene hydrogel and graphene technology, applied in the direction of graphene, nano-carbon, etc., can solve the problems that the excellent performance of the material cannot be effectively exerted, the specific surface area of graphene is reduced, and the stacking of nano-agglomerated sheets is achieved. It is suitable for large-scale commercial production, improves the adsorption effect, and has the effect of simple and easy process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

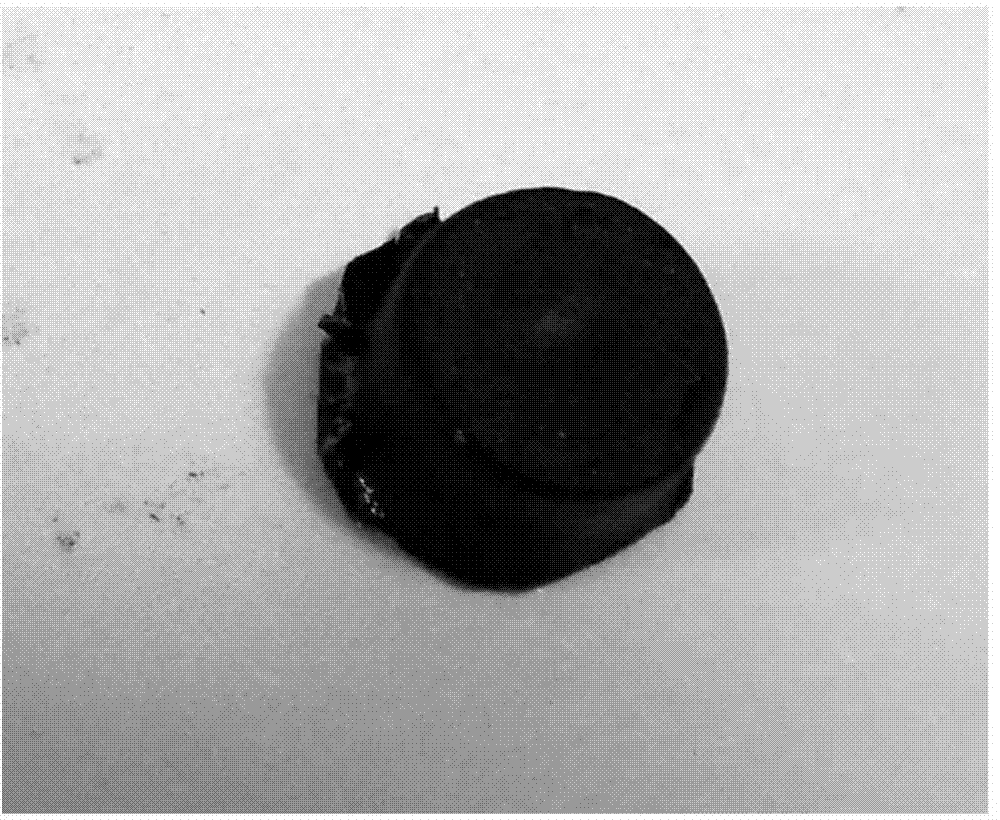

[0031] The method of the invention adopts a chemical reduction method under mild water-bath reaction conditions to reduce graphene oxide so that self-assembly occurs to form graphene hydrogel.

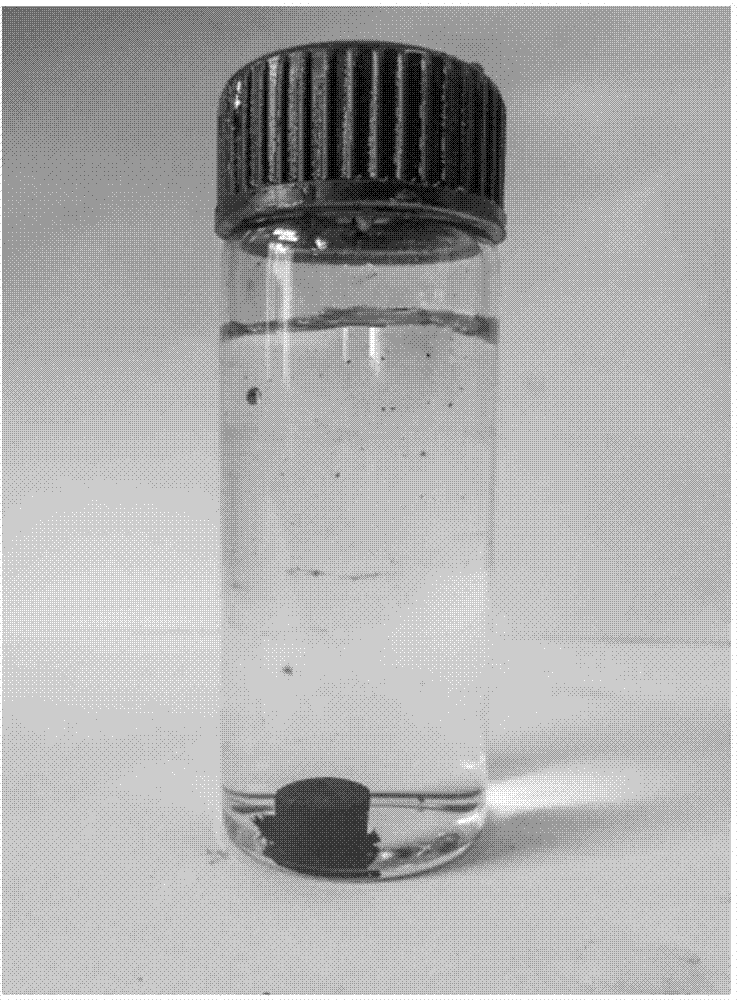

[0032] Graphite oxide is dissolved in water, ultrasonic 12 hours, graphite oxide is separated into the graphene oxide solution that uniform and stable concentration is 1mg / mL; In the graphene oxide solution of gained, according to graphene oxide and reducing agent mass ratio is 1: 1 Add the reducing agent ascorbic acid, ultrasonically disperse for 2 hours, so that the reducing agent and the graphene oxide solution are evenly mixed; divide into beakers according to a certain amount, seal with a parafilm, and put them into a water bath, and control the temperature of the water bath to 70°C , the heating time is 10 hours; after the reduction reaction process is finished, the product is taken out, the obtained graphene hydrogel is soaked in distilled water, and the water is constantly chang...

Embodiment 2

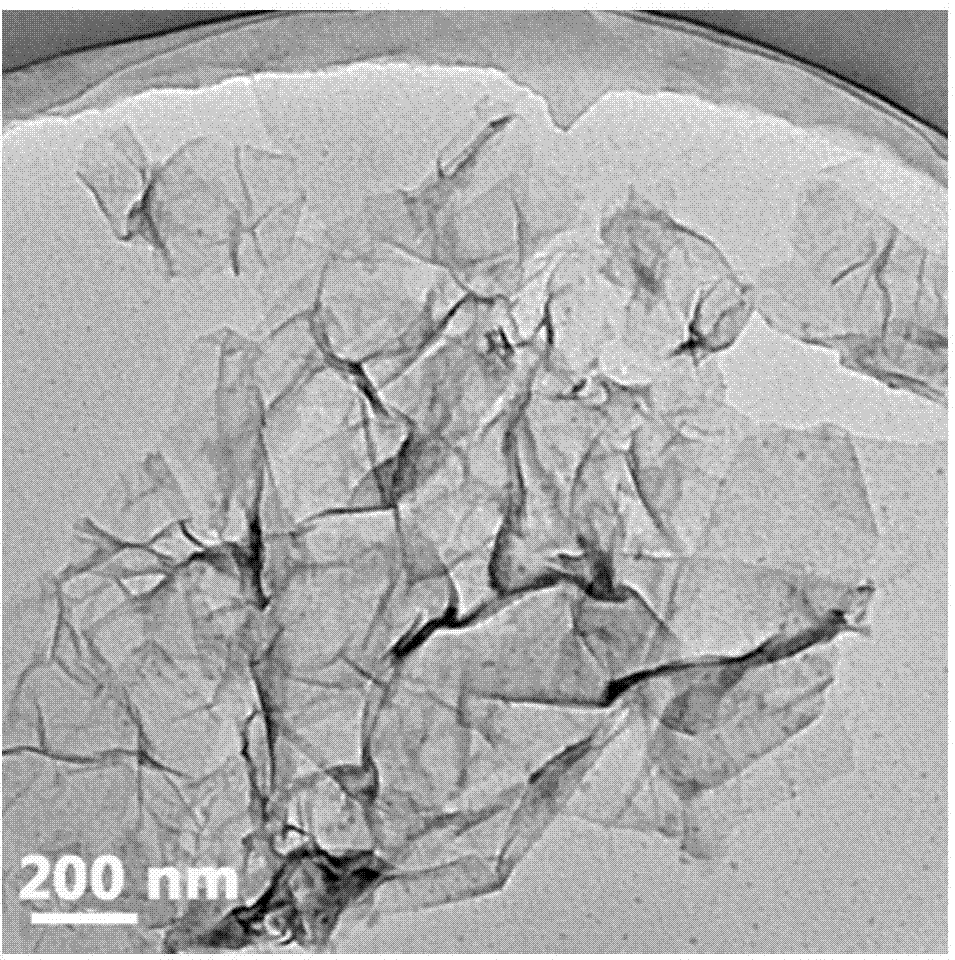

[0034] Graphite oxide is dissolved in water, ultrasonic 10 hours, graphite oxide is separated into the graphene oxide solution that uniform and stable concentration is 2mg / mL; In the graphene oxide solution of gained, according to graphene oxide and reducing agent mass ratio is 1: 1 Add the reducing agent ascorbic acid, ultrasonically disperse for 4 hours, so that the reducing agent and the graphene oxide solution are evenly mixed; according to a certain amount, they are divided into beakers, sealed with a parafilm, and put into a water bath, and the temperature of the water bath is controlled at 75°C , the heating time is 10 hours; after the reduction reaction process is finished, the product is taken out, the obtained graphene hydrogel is soaked in distilled water, and the water is constantly changed for washing to obtain the desired product. The field emission scanning electron microscope picture is as follows figure 2 as shown, figure 2 It is a field emission scanning el...

Embodiment 3

[0037] Graphite oxide is dissolved in water, ultrasonic 4 hours, graphite oxide is separated into the graphene oxide solution that uniform and stable concentration is 4mg / mL; In the graphene oxide solution of gained, according to graphene oxide and reducing agent mass ratio is 3: 1 Add the reducing agent glutathione, ultrasonically disperse for 1.5 hours, so that the reducing agent and the graphene oxide solution are evenly mixed; divide into beakers according to a certain amount, seal with a sealing film, and put them in a water bath to control the temperature of the water bath The temperature is 80°C, and the heating time is 14 hours; after the reduction reaction process is completed, the product is taken out, the obtained graphene hydrogel is soaked in distilled water, and the water is changed continuously for washing to obtain the desired product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com