Fruit cracking prevention liquid fertilizer and preparation method thereof

A technology of anti-cracking fruit and liquid fertilizer, which is applied in the direction of fertilization device, fertilizer mixture, application, etc., can solve the problems of fruit quality and yield adverse effects, affect the safety of fruit consumption, and the effect is not ideal, so as to improve the appearance of products and internal quality, The effect of preventing fruit cracking and preventing small fruit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

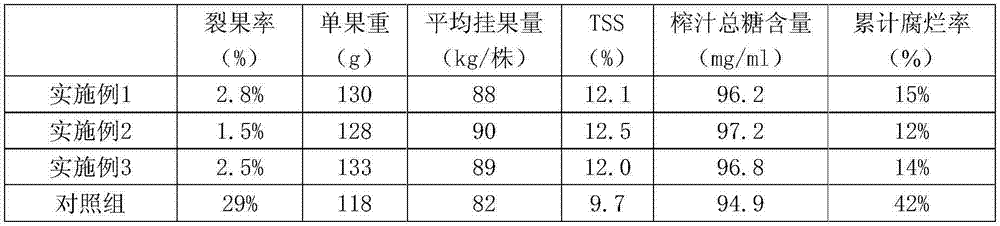

Examples

Embodiment 1

[0021] An anti-cracking fruit liquid fertilizer, using water as a solvent, its formula is: 3 parts of urea, 1 part of compound amino acid chelated zinc, 1 part of zinc acetate, 6 parts of magnesium nitrate, 4 parts of boric acid, 25 parts of phosphorous acid, 14 parts of orthophosphoric acid , 2 parts of phytic acid, 9 parts of potassium hydroxide, 0.1 part of cyclamate, 0.03 part of regulator, 0.05 part of azone, 0.04 part of polyethylene glycol, 1 part of citric acid, and the regulator is B1, B6, BPP equal compound match. Compound amino acid chelated zinc is made of defatted feed grade soybean meal as raw material, hydrolyzed by sulfuric acid, and then chelated by zinc sulfate, with zinc element 11% and crude protein CP 33%.

[0022] Prepare as follows:

[0023] (1) Add urea, compound amino acid chelated zinc, zinc acetate, and magnesium nitrate into water at 40°C in turn under stirring, and after the dissolution is complete, cool to room temperature for use;

[0024] (2) ...

Embodiment 2

[0031] An anti-cracking fruit liquid fertilizer, using water as a solvent, its formula is: 3.7 parts of urea, 1.5 parts of compound amino acid chelated zinc, 1.45 parts of zinc acetate, 6.5 parts of magnesium nitrate, 4.7 parts of boric acid, 26 parts of phosphorous acid, 14.5 parts of orthophosphoric acid , 2.5 parts of phytic acid, 9.8 parts of potassium hydroxide, 0.1 part of cyclamate, 0.33 parts of regulator, 0.1 part of azone, 0.1 part of polyethylene glycol, 2.3 parts of citric acid, in parts by mass. Compound amino acid chelated zinc is the same as embodiment 1.

[0032] Prepare as follows:

[0033] (1) Add urea, compound amino acid chelated zinc, zinc acetate, and magnesium nitrate in proportion to water at 45° C. under stirring, and after the dissolution is complete, cool to room temperature for use;

[0034] (2) Add orthophosphoric acid, phosphorous acid, phytic acid, and boric acid in proportion to the standby liquid obtained in step (1) under stirring, and add po...

Embodiment 3

[0041] An anti-cracking fruit liquid fertilizer, using water as a solvent, its formula is: 4 parts of urea, 2 parts of compound amino acid chelated zinc, 2 parts of zinc acetate, 7 parts of magnesium nitrate, 5 parts of boric acid, 27 parts of phosphorous acid, 15 parts of orthophosphoric acid , 3 parts of phytic acid, 10 parts of potassium hydroxide, 0.3 parts of cyclamate, 00.5 parts of regulator, 0.2 parts of azone, 0.2 parts of polyethylene glycol, 3 parts of citric acid, and the regulators are B1, B6, BPP equivalent compound match. Compound amino acid chelated zinc is the same as embodiment 1.

[0042] Prepare as follows:

[0043] (1) Add urea, compound amino acid chelated zinc, zinc acetate, and magnesium nitrate into water at 50°C in turn under stirring, and after the dissolution is complete, cool to room temperature for use;

[0044](2) Add orthophosphoric acid, phosphorous acid, phytic acid, and boric acid to the standby liquid obtained in step (1) successively unde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com