Method for preparing single-layer molybdenum disulfide flake doped graphene composite film

A single-layer molybdenum disulfide and molybdenum disulfide sheet technology is applied in the field of preparation of graphene composite films, which can solve the problems of less preparation, high requirements, long reaction time, etc., and achieves simple operation, acceptable thickness and volume. Simple control and process preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

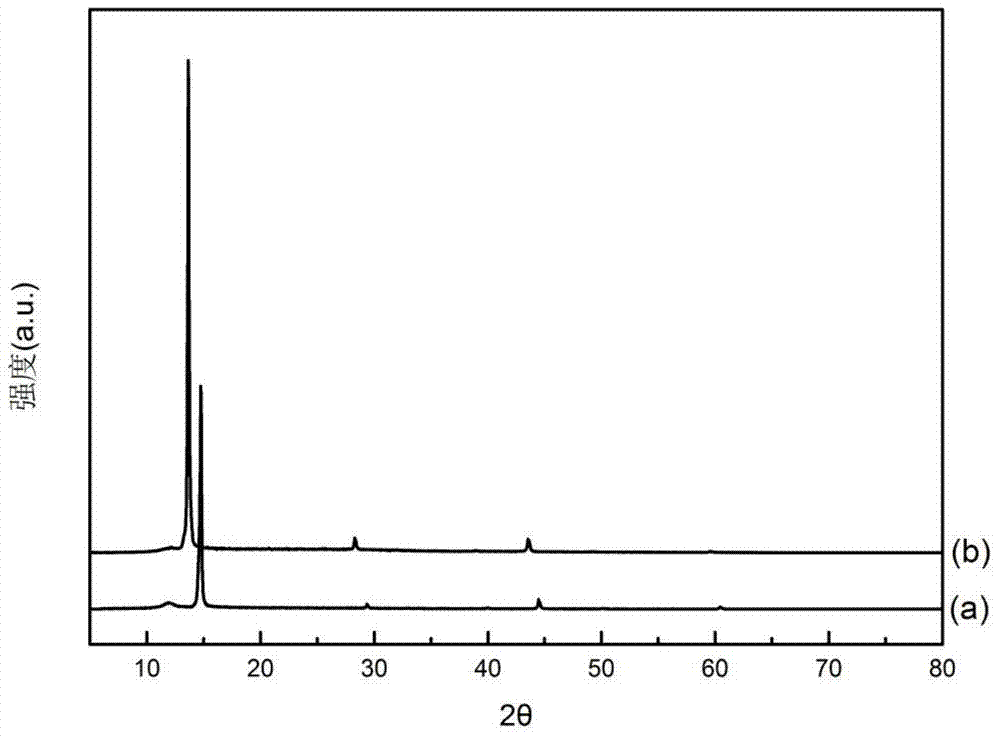

[0033] (1) Preparation of single-layer molybdenum disulfide by lithium ion intercalation method: at room temperature, fully stir and disperse 300mg molybdenum disulfide into 3mL n-butyllithium hexane solution, and react with magneton stirring for 48h under the protection of N2 atmosphere. After the reaction was completed, 10 mL of n-hexane solution was added to dilute the reaction solution. After fully stirring for 2 hours, 50 mL of deionized water was added and stirred for 10 minutes, followed by ultrasonic stripping reaction for 30 minutes to obtain a monomolecular layer of molybdenum disulfide stripped by lithium ion intercalation reaction.

[0034] (2) Graphite oxide was prepared by the Hummers method: 500-mesh graphite powder was oxidized with potassium permanganate and concentrated sulfuric acid, the filter cake obtained by suction filtration was vacuum-dried at 60° C. for 24 hours, and ground to obtain graphite oxide.

[0035] (3) At room temperature, disperse 10 mg of t...

Embodiment 2

[0037] Step (1) and step (2) are the same as (1) and (2) in Example 1.

[0038] (3) At room temperature, disperse 10 mg of the exfoliated monolayer molybdenum disulfide in 100 mL of deionized water, and after fully stirring, ultrasonication in a water bath and a cell pulverizer are performed for 10 min and 30 min, respectively. Weigh 5 mg of graphite oxide powder and ultrasonically disperse in 100 mL of deionized water, and ultrasonically disperse for 20 min. Measure 7.5mL of the dispersed single-layer molybdenum disulfide aqueous solution and graphene oxide aqueous solution respectively, mix well and then sonicate for 10min. The homogeneously mixed 15 mL mixed aqueous solution was filtered through polytetrafluoroethylene with a pore size of 0.6 μm to obtain a suction filter membrane. After the suction filtration, the obtained suction-filtered film and the polytetrafluoroethylene filter membrane were simultaneously placed in a vacuum oven at 80° C. for 2 hours to obtain a graph...

Embodiment 3

[0040] Step (1) and step (2) are the same as (1) and (2) in Example 1.

[0041] (3) Disperse 5 mg of the stripped monolayer molybdenum disulfide in 100 mL of deionized water at room temperature, and after fully stirring, ultrasonication in a water bath and cell pulverizer were performed for 30 min and 60 min, respectively. Weigh 10 mg of graphite oxide powder and ultrasonically disperse in 100 mL of deionized water, and ultrasonically disperse for 20 min. Measure 5 mL of the above dispersed molybdenum disulfide aqueous solution and 10 mL of graphene oxide aqueous solution, mix well and then sonicate for 10 min. The homogeneously mixed 15 mL mixed aqueous solution was filtered through polytetrafluoroethylene with a pore size of 0.5 μm to obtain a suction filter membrane. After the suction filtration, the obtained suction-filtered film and the polytetrafluoroethylene filter membrane were simultaneously placed in a vacuum oven at 60° C. for 2 hours to obtain a graphene oxide com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com