A method for preparing cerium oxide ceramic fiber boards by a precursor impregnation process

The technology of ceramic fiber board and impregnation process is applied in the field of inorganic non-metallic materials and cerium oxide ceramic fiber board production. The effect of uniform and improved drying speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

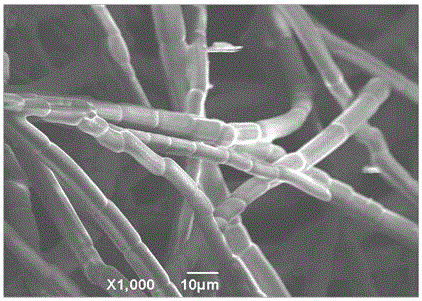

Image

Examples

Embodiment 1

[0023] The preparation method of the cerium oxide ceramic fiberboard of the present invention, concrete operation is as follows:

[0024] (1) Cutting: Cut the 3mm thick organic viscose fiber felt into the required size according to the firing shrinkage ratio;

[0025] (2) Solution preparation: use deionized water and Ce(NO 3 ) 3 ·6H 2 O was prepared into a cerium solution with a concentration of 0.4mol / l, and stirred evenly, then added 0.2% PVP to the solution, stirred while adding, and finally adjusted the pH of the cerium solution to 4 with (1:1) HCl;

[0026] (3) Cerium solution impregnation: put the cut fiber mat into the prepared cerium salt solution, control the solution temperature at 40°C, and immerse for 3 hours;

[0027] (4) Ammonia gas fumigation: take out the impregnated fiber felt from the solution, squeeze it dry, smooth it, and place the fiber felt in a closed container with ammonia water for 3 hours;

[0028] (5) Drying: take out the fiber mat from the airt...

Embodiment 2

[0036] The preparation method of the cerium oxide ceramic fiberboard of the present invention, concrete operation is as follows:

[0037] (1) Cutting: Cut the 6mm thick organic viscose fiber felt into the required size according to the firing shrinkage ratio;

[0038] (2) Solution preparation: use deionized water and Ce(NO 3 ) 3 ·6H 2 O was prepared into a cerium solution with a concentration of 0.6mol / l, and stirred evenly, then added 0.3% PVP to the solution, stirred while adding, and finally adjusted the pH of the cerium solution to 4 with (1:1) HCl;

[0039] (3) Cerium liquid impregnation: put the cut fiber mat into the prepared cerium salt solution, control the solution temperature at 50°C, and impregnate for 2 hours;

[0040] (4) Ammonia fumigation: the impregnated fiber felt is taken out from the solution, squeezed dry, smoothed, and the fiber felt is placed in an airtight container with ammonia water for 6 hours;

[0041] (5) Drying: take out the fiber mat from the a...

Embodiment 3

[0049] The preparation method of the cerium oxide ceramic fiberboard of the present invention, concrete operation is as follows:

[0050] (1) Cutting: Cut the organic viscose fiber felt with a thickness of 12mm into the required size according to the firing shrinkage ratio;

[0051] (2) Solution preparation: use deionized water and Ce(NO 3 ) 3 ·6H 2 O was prepared into a cerium solution with a concentration of 0.25mol / l, and stirred evenly, then added 0.1% PVP to the solution, stirred while adding, and finally adjusted the pH of the cerium solution to 4 with (1:1) HCl;

[0052] (3) Cerium solution impregnation: put the cut fiber mat into the prepared cerium salt solution, control the solution temperature at 55°C, and immerse for 6 hours;

[0053] (4) Ammonia fumigation: take out the impregnated fiber mat from the solution, squeeze it dry, smooth it, and place the fiber mat in a closed container with ammonia water for 10 hours;

[0054] (5) Drying: take out the fiber mat fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com