Method for comprehensive utilization of lignocellulosic biomasses

A lignocellulose and biomass technology, applied in microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve problems such as unfavorable utilization, environmental pollution of waste liquid, and no economy, and improve the viscosity reduction rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Comprehensive utilization of embodiment 1 corn stalks

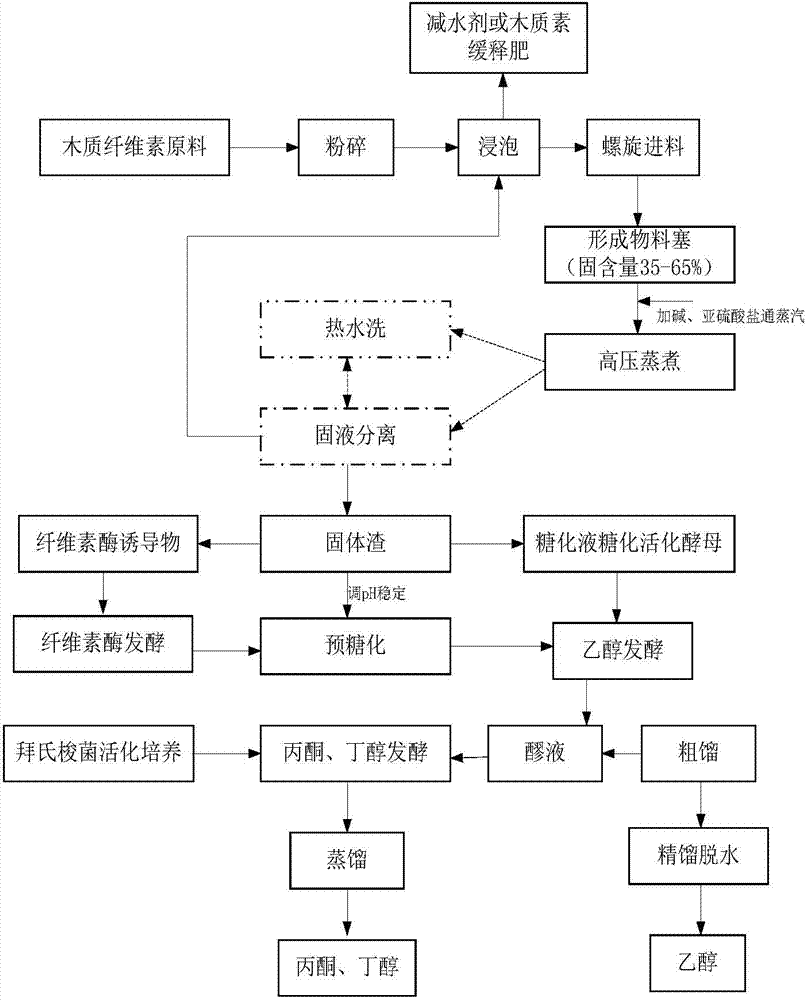

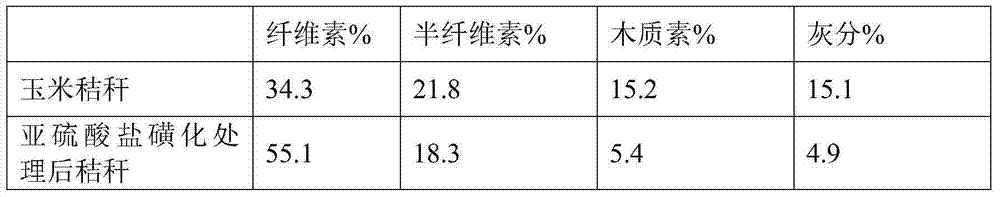

[0038] The flow chart of the comprehensive utilization of corn stalks is as follows: figure 1 As shown, the corn stalks were cut to 6-8 cm, placed in 4 times the mass of water or (filtrate), the amount of sodium hydroxide added was 0.8% of the lignocellulose mass in the corn stalks, and horizontal tube continuous cooking was used. Feed, after forming a material plug, add ammonium bisulfite with 10% lignocellulose mass in corn stalks, the liquid-solid ratio during the reaction is 6:1, after mixing, treat at 185°C for 40 minutes, spray with pressure, collect and spray The slag liquid after release is then rinsed with hot water (water temperature 65°C) and cooled to 65°C, then mixed with water of 1 times the mass of the slag liquid, and filtered to separate the solid from the liquid; the filtrate is reused for soaking materials. When the dry matter content in the liquid is 10-20%, utilize pressure type spray drying e...

Embodiment 2

[0047] The comprehensive utilization of embodiment 2 corn cobs

[0048] The comprehensive utilization flow chart of corn cob is as follows figure 1 As shown, the corn cob is cut to 5 cm, placed in water with 8 times the mass, fed by the material plug method for continuous cooking, and ammonia water and diammonium sulfite are added after the feed, and the amount of ammonia water added is 1.5% of the mass, the addition of diammonium sulfite is 8% of the lignocellulose mass in the corncob, and steam is passed through 160 ° C for 90 minutes. The liquid-solid ratio is 4: 1 in the reaction process. After the slag liquid is released, the slag liquid is separated by the plate and frame, and then the filter cake is washed with 0.5 times hot water at 55°C; the filtrate is reused to soak the material, and the quality of ammonia water and 10% ammonium sulfite can be reduced by 20% after the material plug is formed. The filtered liquid after 10-20% circulation is obtained by pressure spra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com