Chitosan-grafting amino acid magnetic composite microsphere as well as preparation method and application

A technology of magnetic composite microspheres and amino acids, which is applied in the fields of alkali metal compounds, textile industrial wastewater treatment, alkali metal oxides/hydroxides, etc., can solve problems such as difficult and rapid separation, and achieve effective reduction in decolorization, good flocculation, and improved The effect of using efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

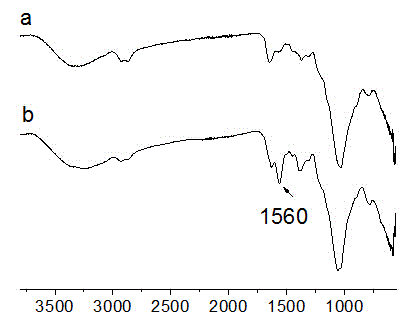

[0031] Chitosan and glutamine (weight ratio: 2:1) were mixed and dissolved in an aqueous solution to prepare a 3% solution. After the solution was uniform, the magnetic particles Fe 3 o 4 Disperse in the above polymer solution by ultrasonic (magnetic particles account for 10% of the total weight of chitosan and glutamine), add cyclohexane (the volume ratio of cyclohexane to chitosan / glutamine mixed solution is 5: 1) After adjusting the pH value to 8, add glutaraldehyde aqueous solution (glutaraldehyde accounts for 1% of the weight of chitosan), and cross-link at 50°C for 1 hour to obtain chitosan-grafted glutamine magnetic composite Microsphere samples. Infrared spectra of pure chitosan microspheres and chitosan-grafted glutamine magnetic composite microspheres figure 1 ,From figure 1 (b) see wavenumber 3250cm -1 Broad peaks are O-H and N-H characteristic absorption peaks; 1560cm -1 It is the characteristic absorption peak of the carbonyl group, thus proving that glutamin...

Embodiment 2

[0035] Chitosan and glutamic acid (weight ratio: 19:1) were mixed and dissolved in an aqueous solution to prepare a 2% solution. After the solution was uniform, the magnetic particles Fe 3 o 4 Disperse in the above polymer solution by ultrasonic (magnetic particles account for 10% of the total weight of chitosan and glutamic acid), add cyclohexane (the volume ratio of cyclohexane and chitosan / glutamic acid mixed solution is 1: 1) After adjusting the pH value to 9, add glutaraldehyde aqueous solution (glutaraldehyde accounts for 3% of the weight of chitosan), and cross-link at 65°C for 3 hours to obtain chitosan-glutamic acid magnetic composite microsphere samples (Glutamic acid accounts for 5% of the total weight of the polymer material). Its performance is similar to embodiment 1.

Embodiment 3

[0037] Dissolve chitosan and ornithine in an aqueous solution with a mass mixing ratio of 1:4 to prepare a solution with a total mass concentration of 10%. After the solution is uniform, the magnetic particles Fe 3 o 4 Disperse in the above polymer solution by ultrasonic (magnetic particles account for 20% of the total weight of chitosan and ornithine), add cyclohexane (the volume ratio of cyclohexane to chitosan / ornithine mixed solution is 10: 1) After adjusting the pH value to 10, add glutaraldehyde aqueous solution (glutaraldehyde accounts for 0.1% of the weight of chitosan), and cross-link at 35°C for 0.5 hours to obtain chitosan-ornithine magnetic composite microspheres Sample (80% ornithine by total weight of polymer material). Its performance is similar to embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com