Method for preparing C3N4 material with N defects and application

A C3N4, defect technology, applied in the field of preparation of nanomaterials, can solve the problems of limiting photocatalytic activity, energy consumption and time-consuming, and achieve the effect of major application prospects, good light absorption performance, and mild conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] A C with N deficiency 3 N 4 The preparation method of photocatalytic material comprises the following steps:

[0059] 1) Dissolve 15g of urea in 50mL of water, then add 10mL of KOH (0.001g / mL) aqueous solution, sonicate for 10 minutes to dissolve, then dry the above mixture in an oven at 80°C overnight;

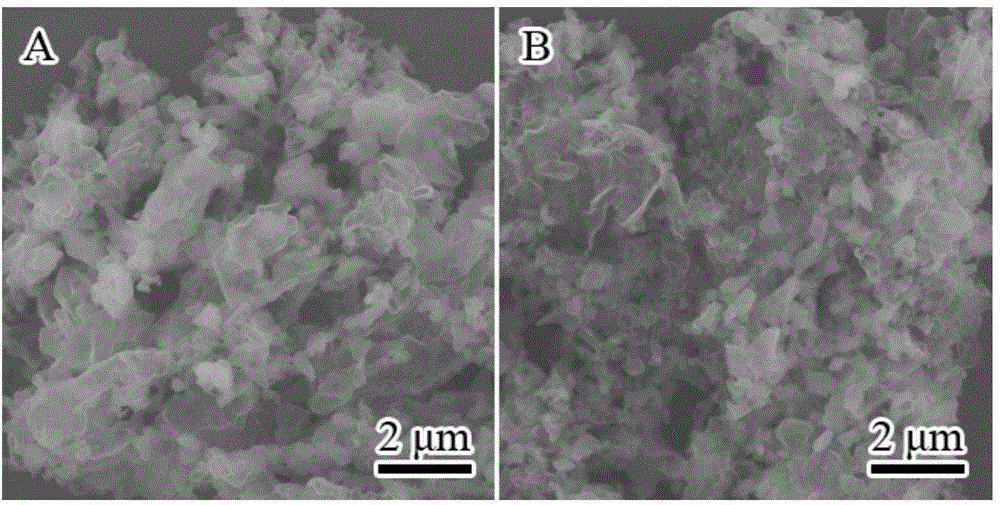

[0060] 2) The dried solid was put into a 100mL magnetic crucible, and calcined in a muffle furnace at 550°C for 4h, wherein the heating rate of the muffle furnace was 5°C min -1 ; get C with N deficiency 3 N 4 , named g-C 3 N x, Its scanning electron microscope pictures are as figure 1 Shown in B.

Embodiment 2

[0071] The comparative example in Example 1 was applied to the experiment of visible light photocatalytic water splitting to produce hydrogen.

[0072] 1) Determine C 3 N 4 As a catalyst, the amount of hydrogen produced and C 3 N 4 The relationship between dosage. Take 1,2,3,4,5,10,15,20,25,30mg Comparative Example C 3 N 4 Put into ten 60mL quartz tubes and add 20mL of lactic acid-water mixture with a volume ratio of 1:3. Nitrogen was passed into the quartz test tube for 30 minutes to remove the oxygen in the tube and sealed with a rubber stopper, and it was stirred and illuminated for 10 hours at room temperature. The light source is a 300W xenon lamp, and a 400nm filter is added to filter out ultraviolet light with a wavelength less than 400nm. The amount of hydrogen produced is measured with Shimadzu GC-2014 gas chromatograph every 1h, such as Image 6 shown. Before illumination, add 1wt% Pt precursor (H 2 PtCl 6 ), nitrogen was passed through for 30 minutes to e...

Embodiment 3

[0080] Repeat embodiment 1, prepare the catalyst of 0.01mg / mL (comparative example C 3 N 4 and C with N deficiency 3 N 4 ) aqueous solution, utilize the Hitachi-F4600 fluorescence spectrum to detect its fluorescence intensity under excitation at 380 nanometers, such as Figure 9 shown.

[0081] The results showed that compared to the comparative example C 3 N 4 ( Figure 9 a curve), C with N defects 3 N 4 ( Figure 9 The fluorescence intensity of curve b) is significantly reduced, which shows that the separation speed of photogenerated electrons and holes of the material has been improved to a certain extent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com