Method for removing hexavalent chromium in wastewater through magnetic adsorbent compounded by chitosan and magnetic biological carbon

A magnetic adsorbent, chitosan technology, applied in the direction of adsorption water/sewage treatment, chemical instruments and methods, water/sewage treatment, etc., can solve the problem that the adsorption performance of magnetic biochar cannot meet the required standards, and achieve surface adsorption Easy site, low cost, simple preparation method and process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

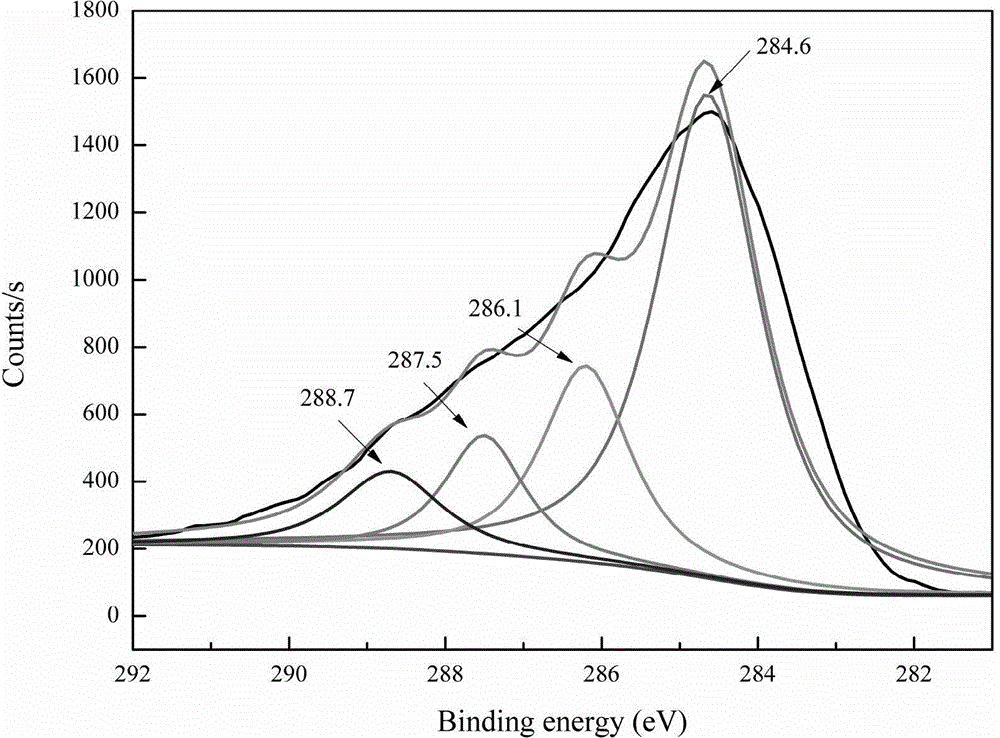

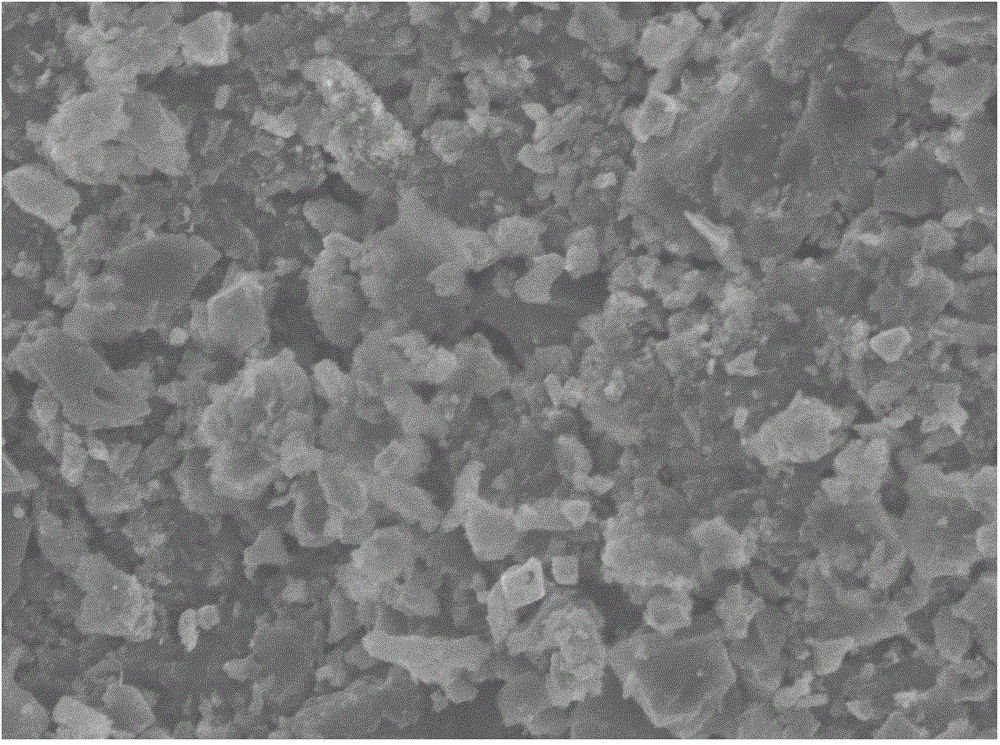

Image

Examples

Embodiment 1

[0025] A kind of chitosan / magnetic biochar composite material of the present invention, this composite material is prepared by following method:

[0026] (1) 40gFeCl 3 ·6H 2 O was dissolved in 120mL deionized water to prepare a certain concentration of ferric chloride solution, soak 20g of water hyacinth biomass into the ferric chloride solution, stir with a glass rod for 10min, then let stand and soak for 12h;

[0027] (2) drying the soaked water hyacinth biomass at 50-60°C, grinding, and passing through a 100-mesh sieve;

[0028] (3) Put the water hyacinth biomass that has been sieved and processed into a tube furnace at 600 ° C and pass N 2 , Burn for 1h to get magnetic biochar. Wash the obtained magnetic biochar with deionized water for 2-3 times, dry at 50-60°C, grind, and pass through a 100-mesh sieve;

[0029] (4) 6g chitosan is dissolved in the acetic acid solution of 2% by volume percentage, is mixed with the chitosan solution that mass percentage is 0.6%;

[003...

Embodiment 2

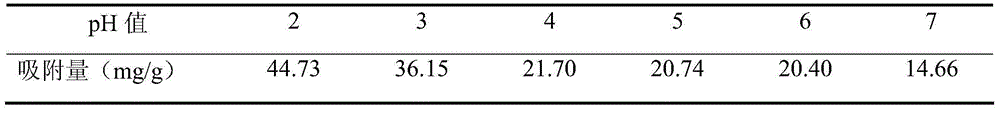

[0033] The chitosan / magnetic biochar composite material prepared in Example 1 is applied to the treatment of hexavalent chromium ion wastewater, comprising the following steps: configure 6 parts of 50mg / L lead solution, use 1mol / L NaOH or HNO 3 Adjust the pH to 2, 3, 4, 5, 6, 7, respectively. Add the above-mentioned chitosan / magnetic biochar composite material, and the amount of adsorbent is 1g / L. They were placed in constant temperature shaking at 30°C. The oscillator speed is 150 rpm, and the oscillation time is 24h. After the reaction is over, place it on a magnet to separate the adsorbent from the solution, and the adsorption process ends. The content of unadsorbed hexavalent chromium in the wastewater was determined by ultraviolet spectrophotometry, and the calculated adsorption results are shown in Table 1.

[0034] Table 1: Effects of different pH values on the removal of hexavalent chromium in wastewater by chitosan / magnetic biochar composites

[0035]

[0036...

Embodiment 3

[0038] The chitosan / magnetic biochar composite material prepared by embodiment 1 is applied to the treatment of hexavalent chromium ion wastewater, comprising the following steps: getting an initial concentration of 100mg / L of hexavalent chromium solution, adjusting the pH value of the solution to 2.0, Add the chitosan / magnetic biochar composite material that embodiment 1 makes, the consumption of this composite is 1g / L, carry out adsorption reaction at 20,30 and 40 ℃ air bath constant temperature oscillator respectively, and the rotating speed is 150rpm, 24 Hours later, the complex was separated from the waste water with a magnet, and the content of unadsorbed hexavalent chromium in the waste water was measured by ultraviolet spectrophotometry. The calculated adsorption results are shown in Table 2.

[0039]Table 2: Chromium adsorption data of chitosan / magnetic biochar composites under different temperature conditions

[0040]

[0041] It can be seen from Table 2 that the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com