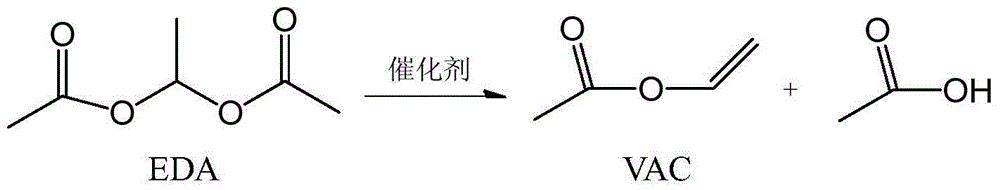

Method for preparing vinyl acetate from ethylidene diacetate through pyrolysis

A technology of ethylene diacetate and vinyl acetate, applied in the field of preparation of vinyl acetate, can solve the problems of difficulty in separating product and catalyst, affecting the purity of VAC, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

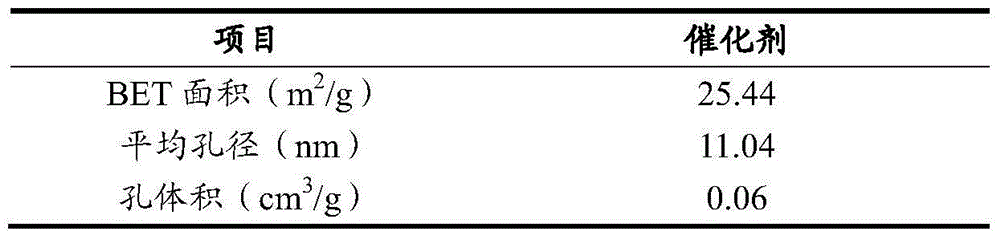

[0016] Put 1g of AlCl 3 Add in 50ml absolute ethanol, accurately weigh commercially available macroporous styrene cation exchange resin (D006 type resin) 7g, simultaneously mix D006 type resin and AlCl 3 Add the solution into a three-necked flask, insert a condenser tube and a thermometer into the three-necked flask, adjust the temperature of the constant temperature magnetic stirrer and the heating mantle, keep it at 40°C-50°C for 20-24 hours, filter, and use deionized water and Wash with acetone until there is no chloride ion (AgNO can be used 3 solution cannot be detected), the washed resin is dried in a vacuum oven to constant weight (drying temperature is preferably 80 ° C), and AlCl 3 Modified macroporous styrene cation exchange resin, its parameters are shown in Table 1.

[0017] Table 1

[0018]

Embodiment 2

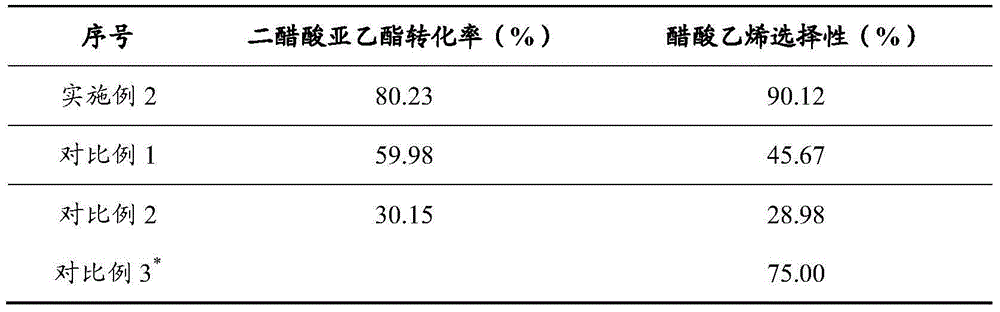

[0020] Take by weighing ethylene diacetate 120g, the AlCl prepared by embodiment 1 3 Modified macroporous styrene cation exchange resin (catalyst) 2.6g, joins in the 500ml there-necked flask, at normal pressure (1atm) and temperature is 140 ℃, the state keeps 1.5h, the product adopts gas chromatographic analyzer to carry out data analysis Analysis and processing, the results are shown in Table 2,

[0021] Gas chromatographic column: stationary phase HP-5, FID, vaporization temperature 250°C, column temperature initial temperature 50°C, temperature programmed to 250°C at 8°C / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com